angle roll forming machine supplier

The Role of Angle Roll Forming Machines in Modern Manufacturing

In today's manufacturing landscape, the demand for efficiency, precision, and versatility is at an all-time high. Among the various technologies that have evolved to meet these demands, angle roll forming machines have gained significant prominence. These machines are essential in fabricating metal components used in diverse applications, from construction to automotive industries. As a result, the role of angle roll forming machines and their suppliers has become crucial in ensuring the success of manufacturing operations.

What is an Angle Roll Forming Machine?

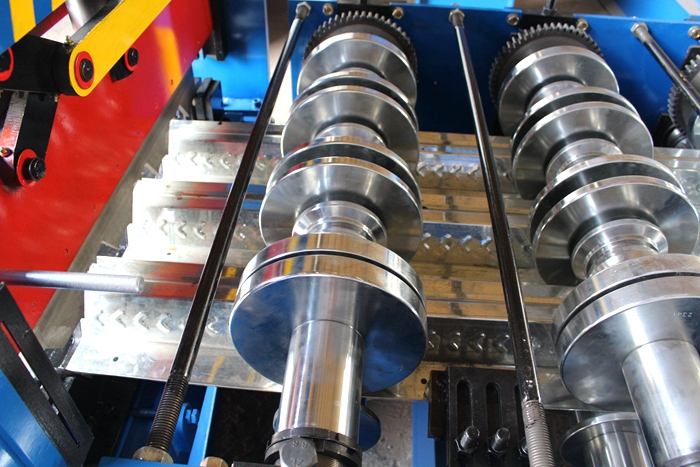

An angle roll forming machine is a specialized piece of equipment designed to bend and shape metal sheets into various angles or profiles, most commonly L-shaped or U-shaped sections. This process is vital for producing frames, supports, and brackets that are integral to many structures and machines. The machine operates by passing the metal through rotating rollers, which gradually bend the material to the desired shape. The end result is not only accurate in terms of measurements but also exhibits a high degree of uniformity across production runs.

Significance of Suppliers in the Industry

The role of suppliers in the angle roll forming machine market extends beyond simply providing equipment. They are responsible for delivering comprehensive solutions that encompass the machinery, technical support, and maintenance services. A reliable supplier will have a deep understanding of their client's needs and the specific requirements of the projects at hand. This relationship is essential for achieving optimal performance of the machines and ensuring that production schedules are met without interruption.

Factors to Consider When Choosing a Supplier

When selecting an angle roll forming machine supplier, manufacturers should consider several key factors

1. Experience and Reputation A supplier with years of experience in the industry will have a proven track record of delivering quality machines. Checking customer reviews and testimonials can provide insights into their reliability and service quality.

angle roll forming machine supplier

2. Product Range Different industries may require various types of angle roll forming machines. It is beneficial to choose a supplier that offers a wide range of machines tailored to specific applications.

3. Technical Support After-sales service is crucial in maintaining the efficiency of forming machines. Suppliers should provide comprehensive support, including installation, maintenance, and training for operators.

4. Innovation and Technology As technology evolves, so do the capabilities of forming machines. Suppliers that invest in research and development are likely to offer the latest advancements, enhancing production efficiency and output quality.

5. Customization Options Every manufacturing operation has unique requirements. A supplier that offers customized solutions can help businesses achieve their specific goals, ensuring optimal machine performance.

Economic Benefits of Using Angle Roll Forming Machines

Investing in angle roll forming machines can yield significant economic benefits for manufacturers. Firstly, the machines can enhance productivity, as they are capable of handling large volumes of material with speed and precision. This leads to reduced labor costs and shorter lead times. Secondly, the high level of accuracy achieved with roll forming minimizes material wastage, which is a critical consideration in terms of cost-efficiency and sustainability.

Furthermore, the versatility of angle roll forming allows manufacturers to diversify their product offerings, thereby expanding their market reach. By incorporating different profiles and shapes, businesses can cater to a broader range of industries and applications.

Conclusion

In conclusion, angle roll forming machines play an indispensable role in modern manufacturing, streamlining processes and increasing production capabilities. The relationship between manufacturers and suppliers is foundational to the success of these machines. By choosing a knowledgeable and reliable supplier, manufacturers can harness the full potential of angle roll forming technology to meet their production goals efficiently. As industries continue to evolve, those who leverage the advantages of advanced forming machines will undoubtedly find themselves well-positioned to thrive in a competitive marketplace.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025