Vijesti

-

Stretch forming is a type of metalworking most commonly used in aerospace applications. During the metal stretch forming process (also known as ‘wrap forming’), metal sheets or extrusions are stretched to exceed their inherent elastic limit and formed around contoured dies to create the desired shape. This “stretching” results in an increased material yield strength and a stronger finished part. Since stretch forming machines maintain constant tension of the metal throughout the process, they minimize imperfections and wrinkles.Čitaj više

Stretch forming is a type of metalworking most commonly used in aerospace applications. During the metal stretch forming process (also known as ‘wrap forming’), metal sheets or extrusions are stretched to exceed their inherent elastic limit and formed around contoured dies to create the desired shape. This “stretching” results in an increased material yield strength and a stronger finished part. Since stretch forming machines maintain constant tension of the metal throughout the process, they minimize imperfections and wrinkles.Čitaj više -

Mobile Precision: Unleashing Efficiency with Portable Standing Seam Roof Panel Roll Forming MachinesIn the era of technological marvels, the "Portable Standing Seam Roof Panel Roll Forming Machine" emerges as a game-changer in the construction industry, bringing unparalleled efficiency and precision to the fabrication of roof panels.Čitaj više

Mobile Precision: Unleashing Efficiency with Portable Standing Seam Roof Panel Roll Forming MachinesIn the era of technological marvels, the "Portable Standing Seam Roof Panel Roll Forming Machine" emerges as a game-changer in the construction industry, bringing unparalleled efficiency and precision to the fabrication of roof panels.Čitaj više -

Metal roofing machines owe their exceptional performance to advanced technology and innovative design. From high-strength steel construction to automated production systems, these machines showcase efficiency, durability, and environmental consciousness. This article explores their diverse applications, impact on energy consumption, and the challenges and prospects in the industry.Čitaj više

Metal roofing machines owe their exceptional performance to advanced technology and innovative design. From high-strength steel construction to automated production systems, these machines showcase efficiency, durability, and environmental consciousness. This article explores their diverse applications, impact on energy consumption, and the challenges and prospects in the industry.Čitaj više -

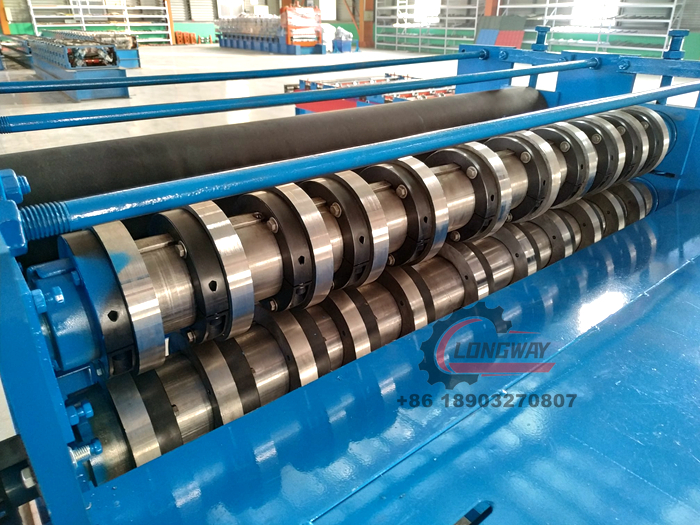

Roll forming machines are widely used in the manufacturing industry for producing various types of metal products. These machines use a series of rollers to shape and form metal sheets into different shapes and sizes. The precision and versatility of roll forming machines make them an essential tool for shaping the future of manufacturing.Čitaj više

Roll forming machines are widely used in the manufacturing industry for producing various types of metal products. These machines use a series of rollers to shape and form metal sheets into different shapes and sizes. The precision and versatility of roll forming machines make them an essential tool for shaping the future of manufacturing.Čitaj više -

Exploring the Dynamics and Benefits of Light Steel Ceiling FormingThis article delves into the inner workings and advantages of the Light Steel Ceiling CU Channel Roll Forming Machine. Discover how this machine achieves efficient production and precise forming, enticing readers to explore its capabilities for their manufacturing needs.Čitaj više

Exploring the Dynamics and Benefits of Light Steel Ceiling FormingThis article delves into the inner workings and advantages of the Light Steel Ceiling CU Channel Roll Forming Machine. Discover how this machine achieves efficient production and precise forming, enticing readers to explore its capabilities for their manufacturing needs.Čitaj više -

Embarking on Precision: Understanding the Essence of Roll Forming MachinesThis article unravels the intricacies of roll forming machines, delving into their operational principles and widespread applications in sectors like construction and manufacturing. Explore how these machines intricately bend and press metal sheets continuously to craft the desired shapes and dimensions.Čitaj više

Embarking on Precision: Understanding the Essence of Roll Forming MachinesThis article unravels the intricacies of roll forming machines, delving into their operational principles and widespread applications in sectors like construction and manufacturing. Explore how these machines intricately bend and press metal sheets continuously to craft the desired shapes and dimensions.Čitaj više -

Unveiling the Strengths of Metal Roofing Machines: Efficiency, Durability, and Environmental FriendlinessThis article delves into the myriad advantages of metal roofing machines, exploring how these cutting-edge technologies contribute to efficient production, long-lasting structures, and eco-friendly practices. Discover how the utilization of metal roofing machines enhances the efficiency and quality of construction projects while minimizing environmental impact.Čitaj više

Unveiling the Strengths of Metal Roofing Machines: Efficiency, Durability, and Environmental FriendlinessThis article delves into the myriad advantages of metal roofing machines, exploring how these cutting-edge technologies contribute to efficient production, long-lasting structures, and eco-friendly practices. Discover how the utilization of metal roofing machines enhances the efficiency and quality of construction projects while minimizing environmental impact.Čitaj više -

Cutting to Desired Lengths – Exploring the Versatile World of Cutting MachineryCutting machinery has revolutionized industries by providing solutions to tailor materials to specific lengths. This article delves into the machine designed for cutting materials to desired lengths, discussing its applications across various industries, including metal and wood processing. Highlighting its advantages such as efficiency, precision, and reliability, we explore how this machinery meets diverse needs.Čitaj više

Cutting to Desired Lengths – Exploring the Versatile World of Cutting MachineryCutting machinery has revolutionized industries by providing solutions to tailor materials to specific lengths. This article delves into the machine designed for cutting materials to desired lengths, discussing its applications across various industries, including metal and wood processing. Highlighting its advantages such as efficiency, precision, and reliability, we explore how this machinery meets diverse needs.Čitaj više -

Understanding these working principles is essential for optimizing the performance of metal roofing machinery. Manufacturers and operators need to ensure precise calibration and maintenance to achieve consistent and high-quality results in the production of metal roofing materials.Čitaj više

Understanding these working principles is essential for optimizing the performance of metal roofing machinery. Manufacturers and operators need to ensure precise calibration and maintenance to achieve consistent and high-quality results in the production of metal roofing materials.Čitaj više -

Mission creep is a common problem in manufacturing. The initial success of a product can trigger an unexpected level of demand, ironically leading to production volumes that are less cost-effective.Čitaj više

Mission creep is a common problem in manufacturing. The initial success of a product can trigger an unexpected level of demand, ironically leading to production volumes that are less cost-effective.Čitaj više -

High-strength steels have become increasingly popular for use in the automotive industry mainly because of their very high strength-to-weight ratios. However, formability in these same materials remains a problem; the yield strength is very high in these metals, which means the springback is very high. This makes roll forming parts a challenge. However, the efficiency of roll forming makes it an ideal process for producing certain parts compared to hot stamping. If you intend to roll form high-strength steels, it’s important to understand how you have to adjust your equipment to get the best results. You also have to consider the steel you are purchasing and how that is affecting the process.Čitaj više

High-strength steels have become increasingly popular for use in the automotive industry mainly because of their very high strength-to-weight ratios. However, formability in these same materials remains a problem; the yield strength is very high in these metals, which means the springback is very high. This makes roll forming parts a challenge. However, the efficiency of roll forming makes it an ideal process for producing certain parts compared to hot stamping. If you intend to roll form high-strength steels, it’s important to understand how you have to adjust your equipment to get the best results. You also have to consider the steel you are purchasing and how that is affecting the process.Čitaj više -

Roll forming systems used to run at a very slow speed, about 50 ft./min., Which made it easy to handle everything manually at the end of the line. These days roll formers can run anywhere from 300 to 500 ft./min. Speed can make parts hard to handle, but so can part configuration, which has become more complex as machine capabilities have expanded.Čitaj više

Roll forming systems used to run at a very slow speed, about 50 ft./min., Which made it easy to handle everything manually at the end of the line. These days roll formers can run anywhere from 300 to 500 ft./min. Speed can make parts hard to handle, but so can part configuration, which has become more complex as machine capabilities have expanded.Čitaj više