The Essential Guide to Floor Deck Roll Forming Machines

When searching for a high-quality floor deck roll forming machine manufacturer, it's essential to find a company that combines experience, technology, and reliable customer service. The floor deck roll forming machine manufacturer is responsible for designing and producing machines that can efficiently transform flat metal sheets into complex shapes, which are then used in various industries, including construction, roofing, and flooring. These machines are used to create metal decks that serve as a base for concrete floors or roofs, offering structural integrity and support. The expertise of a floor deck roll forming machine manufacturer ensures that the machines are durable, reliable, and capable of producing high-quality metal decks that meet industry standards. Manufacturers must also provide customer service, maintenance, and training to ensure seamless operations and long-lasting equipment.

OEM Floor Deck Roll Forming Machine for Customization

An OEM floor deck roll forming machine allows businesses to tailor the machine according to their specific needs. OEM (Original Equipment Manufacturer) machines are often customizable, enabling businesses to adapt the machinery to unique production requirements. For companies that require flexibility in terms of size, shape, and design of the floor deck, investing in an OEM floor deck roll forming machine is a game-changer. These machines are built with advanced technology and can produce metal decks in a variety of profiles, widths, and thicknesses, all while maintaining high efficiency and precision. Choosing an OEM floor deck roll forming machine ensures that companies can optimize their production processes and meet the specific demands of their customers, whether they are working with different types of metal or custom deck designs.

The Advantages of Metal Deck Roll Forming Machines

The metal deck roll forming machine plays a significant role in creating metal decks for commercial, industrial, and residential applications. The machine works by feeding metal sheets through a series of rollers that progressively shape and form the sheets into a desired deck profile. A metal deck roll forming machine offers many advantages, including high-speed production, minimal material waste, and consistent results. These machines are engineered to handle various materials, including galvanized steel, stainless steel, and aluminum, making them highly versatile. For industries involved in construction and infrastructure, the ability to produce strong, reliable, and cost-effective metal decks quickly is a competitive edge. A metal deck roll forming machine is crucial for streamlining production lines and reducing labor costs while ensuring the durability and strength of the resulting metal decks.

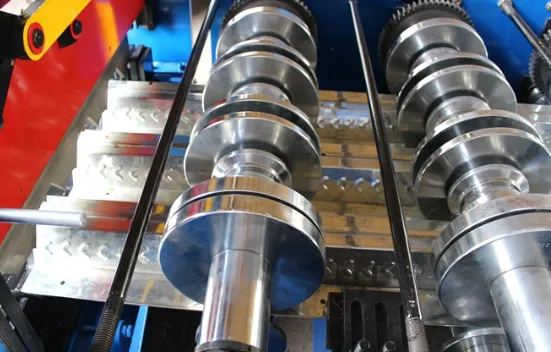

How Deck Roll Forming Machines Work

A deck roll forming machine is designed to transform flat metal sheets into specific profiles that are used for constructing floors and roofs. These machines operate by feeding metal sheets into rollers that gradually shape the material into the desired deck profile. The process is continuous, making deck roll forming machines highly efficient for large-scale production. These machines offer versatility in terms of thickness and material type, allowing manufacturers to create decks from steel, aluminum, and other metals. The deck roll forming machine is essential in producing metal decks that meet the structural requirements of modern buildings and other infrastructure projects. These machines not only increase production speeds but also reduce material waste, making them an environmentally and economically beneficial investment for manufacturers in the construction industry.

Choosing the Right Floor Deck Roll Forming Machine Material

The floor deck roll forming machine material is an important factor when selecting a machine for your production line. The material used in the machine's construction affects its durability, longevity, and performance. High-quality materials ensure that the floor deck roll forming machine can handle various metals without wear and tear over time. Steel, particularly high-grade steel, is commonly used for its strength, resistance to corrosion, and ability to withstand the forces exerted during the roll forming process. Additionally, the choice of floor deck roll forming machine material also impacts the speed and efficiency of the machine. Machines made with high-quality materials are able to operate at higher speeds while maintaining precision and reducing downtime. It’s important to choose a machine made from durable and reliable materials to ensure long-term performance and minimize maintenance costs.

Floor Deck Roll Forming Machines FAQs

What are the benefits of purchasing from a floor deck roll forming machine manufacturer?

Buying from a trusted floor deck roll forming machine manufacturer guarantees you get high-quality equipment tailored to your production needs. The manufacturer can provide expert guidance, maintenance support, and custom solutions to ensure your machine performs optimally.

What customization options are available for an OEM floor deck roll forming machine?

An OEM floor deck roll forming machine can be customized based on your specific production requirements, including the size and shape of the metal deck, speed of production, and material types. Customization options allow for a machine that fits perfectly within your workflow.

How does a metal deck roll forming machine improve production efficiency?

A metal deck roll forming machine increases production efficiency by automating the shaping of metal sheets into deck profiles. It reduces the need for manual labor, speeds up production, and ensures consistent quality in every deck produced.

What materials can be used with a deck roll forming machine?

A deck roll forming machine is versatile and can process a variety of materials such as steel, stainless steel, aluminum, and galvanized steel. The machine can be adjusted to accommodate different material thicknesses and widths.

Why is the choice of floor deck roll forming machine material important?

The floor deck roll forming machine material affects the machine's durability and performance. Machines made with high-quality materials, such as high-grade steel, ensure longer operational life, increased efficiency, and minimal maintenance, which are essential for high-volume production environments.

-

Corrugated iron roofing sheet making machine with CE, AutoНовостиNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyНовостиNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCНовостиNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseНовостиNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseНовостиNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableНовостиNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CEНовостиNov.11, 2025