Understanding Gutter Machine Accessories and Attachments

Gutter machines are essential tools for producing custom gutters, but their functionality can be greatly enhanced with the right accessories and attachments. These components not only expand the versatility of the machine but also improve efficiency, precision, and the overall quality of the gutters produced. Whether you're operating a small business or managing a large-scale manufacturing operation, understanding the various gutter machine accessories and attachments can help you optimize your production process and offer a broader range of services to your clients. This article explores the key accessories and attachments that can elevate the performance of your gutter machine.

The Role of Gutter Machine Accessories

Gutter molding machine accessories serve several important purposes, including improving the accuracy of cuts, enabling the use of different materials, and increasing the speed of production. Many of these accessories are designed to add functionality without requiring a complete overhaul of the machine. Instead, they enhance specific capabilities, allowing users to tailor the machine to their specific needs.

One of the main advantages of these accessories is their ability to offer customization. Since gutter making machines are used to produce gutters in various profiles and sizes, accessories help in producing custom designs that meet the unique requirements of each job. Whether you're working on residential gutters or commercial-grade installations, these add-ons ensure your machine is versatile enough to handle any project.

Common Gutter Machine Attachments

Several key attachments can be added to gutter machines to improve both their performance and versatility. These attachments can vary depending on the type of machine and the specific model, but they generally fall into a few broad categories.

Roll Forming Dies

Roll forming dies are essential attachments for shaping the gutter material as it is fed through the machine. These dies are designed to produce different gutter profiles, allowing the machine to create gutters of various sizes and shapes, such as K-style, half-round, or box gutters. Some gutter machines come with interchangeable dies, while others require separate attachments for each profile. The ability to quickly change dies ensures flexibility and adaptability, enabling contractors to offer a wide variety of gutter styles without needing multiple machines.

Gutter Machine Shaping Tools

In addition to roll forming dies, gutter shaping tools are used to fine-tune the edges and curves of the gutter profiles. These tools help ensure the gutters maintain their shape and structural integrity, even under stress or pressure from water flow. Common shaping tools include forming rollers, guide rails, and pinch rollers, which work together to ensure that the gutter profile remains consistent and free from imperfections.

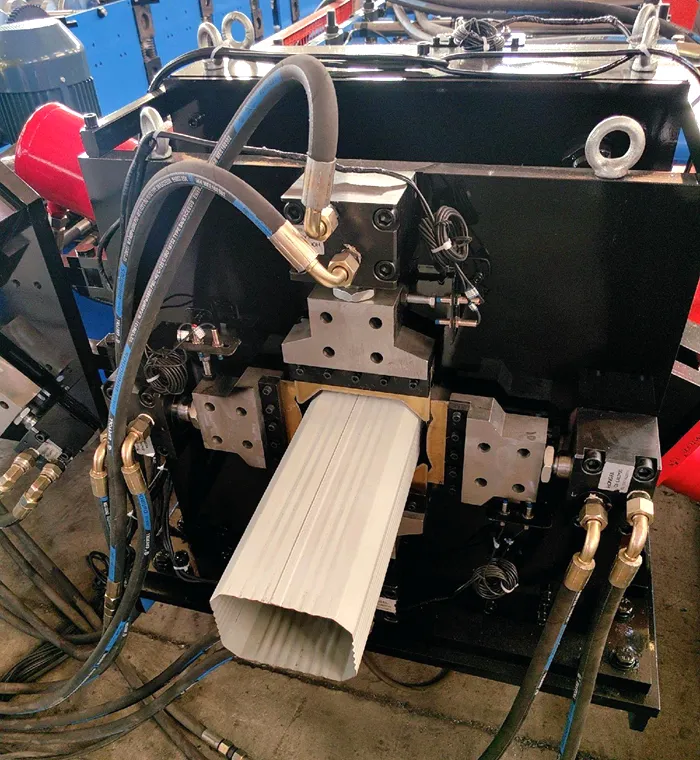

Downspout Machines and Attachments

Downspout machines are often attached to gutter machines to streamline the production of matching downspouts. These attachments can form downspouts in various sizes and shapes, such as round or rectangular profiles, to complement the gutters produced. Some machines feature integrated downspout formers, which allow the operator to seamlessly transition between producing gutters and downspouts. For businesses looking to offer complete gutter systems, investing in these attachments can significantly improve efficiency and reduce the need for additional equipment.

Specialized Accessories for Enhanced Functionality About Máquina de Calhas

Beyond the basic attachments, specialized accessories can be added to gutter machines to improve production speed, reduce downtime, and increase material handling efficiency.

Cutting Blades and Shears

Cutting blades and shears are essential for accurately cutting the gutter material to the required length. Some gutter machines come equipped with integrated cutting systems, but for those who require more precision or faster cutting speeds, additional cutting blades and shears can be attached. These blades are often adjustable to ensure clean, precise cuts regardless of the material or size of the gutter being produced. Upgrading to high-quality cutting accessories can improve overall accuracy and reduce the risk of defects in the finished product.

Splice Plates and Jointers

When producing longer gutters, splice plates and jointers are necessary for connecting multiple sections together. These accessories ensure that the gutters are securely joined without compromising the integrity or aesthetics of the final product. Splice plates are available in different sizes to match the gutter profile, and they are typically used in conjunction with fasteners or welding equipment to ensure a tight, leak-proof connection. For contractors working on large-scale installations, having reliable splice plates and jointers can save time and enhance the quality of the work.

Coil Holders and Feed Systems

Gutter machines often require large rolls of coil material, such as aluminum or steel, to produce gutters. Coil holders and automatic feed systems help manage the material as it is fed into the machine, reducing the risk of material wastage and ensuring consistent feed rates. By automating the feeding process, these accessories can help improve production speeds and reduce the labor required to manually handle the material. Coil holders can also help reduce tangling and damage to the material, ensuring a smoother production process.

-

Corrugated iron roofing sheet making machine with CE, AutoNotíciasNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNotíciasNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNotíciasNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNotíciasNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNotíciasNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNotíciasNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENotíciasNov.11, 2025