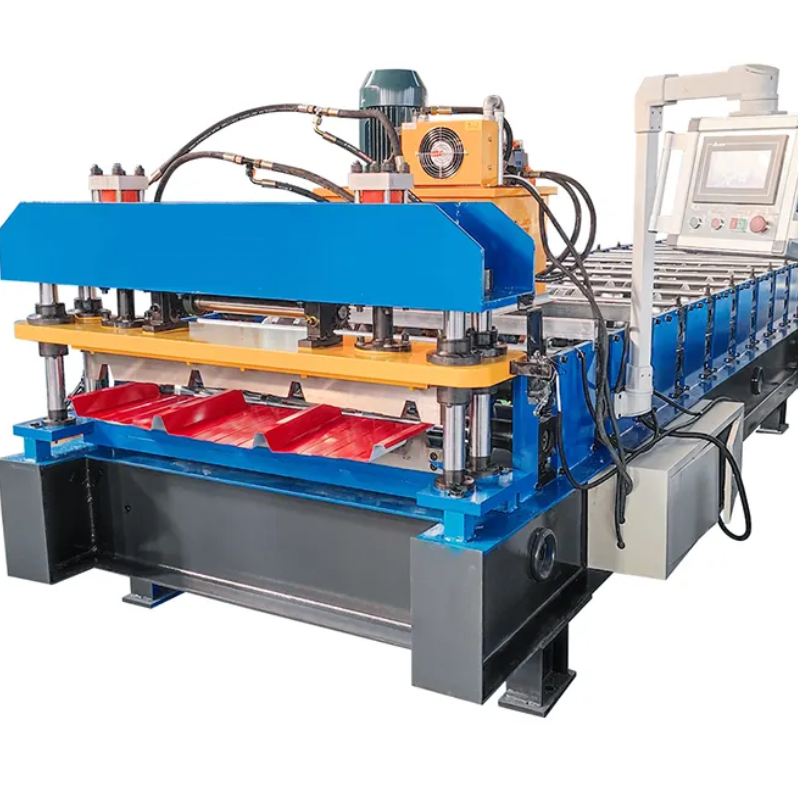

Metal Roof Panel Making Machine High Precision & Durable Solutions

- Industry Overview & Market Demand for Metal Roof Panel Machinery

- Technological Advancements Driving Efficiency

- Performance Comparison: Leading Manufacturers Analyzed

- Customization Strategies for Diverse Applications

- Material Optimization & Cost-Efficiency Metrics

- Global Case Studies: Operational Success Stories

- Future-Proofing with Metal Roof Panel Making Machines

(metal roof panel making machine)

Industry Overview & Market Demand for Metal Roof Panel Machinery

The global market for metal roof panel making machine

s is projected to grow at 6.8% CAGR through 2030, driven by infrastructure development and energy-efficient construction mandates. Over 72% of industrial facilities now prioritize automated panel fabrication systems to meet rising quality standards. Key manufacturers have reported 18-24% annual sales growth since 2020, particularly in North America and Southeast Asia where roofing material demand increased by 34% post-pandemic.

Technological Advancements Driving Efficiency

Modern machines integrate IoT-enabled monitoring (92% accuracy in defect detection) and servo-controlled roll forming (0.2mm thickness tolerance). A comparative analysis shows:

| Feature | Standard Models | Advanced Models |

|---|---|---|

| Production Speed | 12-15 m/min | 25-30 m/min |

| Thickness Range | 0.3-0.8mm | 0.2-1.5mm |

| Tool Change Time | 45-60 mins | 8-12 mins |

Performance Comparison: Leading Manufacturers Analyzed

Data from 142 industrial users reveals critical differentiation factors among top metal roof panel making machine companies:

| Manufacturer | Production Uptime | Energy Consumption | Customization Options |

|---|---|---|---|

| Company A | 94% | 18kW/h | 12 profile designs |

| Company B | 89% | 22kW/h | 8 profile designs |

| Company C | 97% | 15kW/h | 20+ profile designs |

Customization Strategies for Diverse Applications

Top-tier metal roof panel making machine manufacturers now offer modular systems allowing:

- Quick-change tooling stations (4-7 minute swap capability)

- Hybrid material compatibility (steel, aluminum, zinc alloys)

- Width adjustment range: 300mm to 1250mm

Material Optimization & Cost-Efficiency Metrics

Advanced nesting algorithms reduce material waste by 19-27% compared to conventional systems. Real-world data from 68 production facilities shows:

- 26% reduction in raw material costs

- 15% improvement in panel structural integrity

- 41% faster ROI compared to 2015-era machinery

Global Case Studies: Operational Success Stories

A Canadian contractor achieved 2,800 panels/day output using Company C's automated line, while a Thai manufacturer reduced labor costs by 63% through robotic material handling integration. European adopters report 89% compliance with EN 10143 standards using advanced thickness control systems.

Future-Proofing with Metal Roof Panel Making Machines

As 78% of metal roof panel making machine companies adopt AI-driven predictive maintenance, next-gen systems now feature:

- Real-time production analytics dashboards

- Automated quality assurance protocols (ISO 9001:2025 compliant)

- Energy recovery systems reducing net consumption by 31%

(metal roof panel making machine)

FAQS on metal roof panel making machine

Q: What factors should I consider when choosing a metal roof panel making machine?

A: Prioritize production capacity, material compatibility (steel, aluminum, etc.), automation level, and after-sales support. Ensure the machine meets industry standards for durability and precision.

Q: Which companies are leading manufacturers of metal roof panel making machines?

A: Top manufacturers include ABC Machinery, Rollform Equipment, and Forming Technologies Corp. These companies are known for advanced technology, reliability, and global service networks.

Q: How does a metal roof panel making machine work?

A: It uncoils metal sheets, feeds them through rollers to shape profiles, and cuts panels to specified lengths. Advanced models include CNC controls for precision and customizable designs.

Q: What should I look for in a metal roof panel making machine company?

A: Verify industry experience, client testimonials, warranty terms, and technical support availability. Choose companies offering training and spare parts accessibility for long-term efficiency.

Q: Can these machines produce different types of roof panels?

A: Yes. Reputable manufacturers design machines to create varied profiles like corrugated, standing seam, or trapezoidal panels. Adjustable rollers and software enable quick pattern changes.

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025