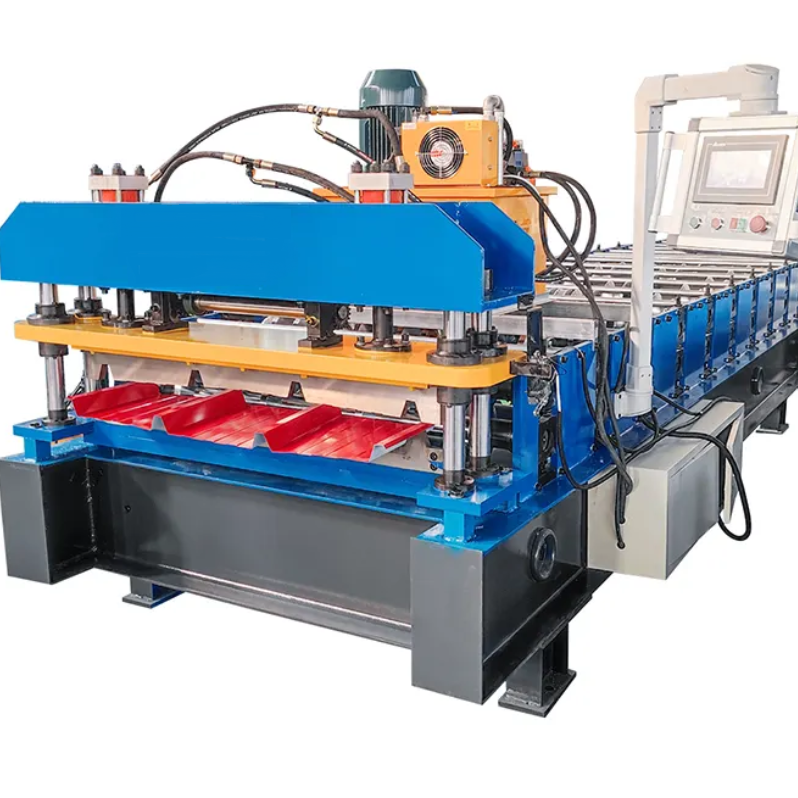

T18 Metal Roofing Sheet Roll Forming Equipment for High-Quality Roof Production

The T18 20 Metal Roofing Sheet Roll Forming Machine A Comprehensive Overview

In the world of construction and manufacturing, efficiency and precision are paramount. One of the key contributors to achieving these goals is the technology behind roll forming machines. Among the various models available, the T18 20 metal roofing sheet roll forming machine stands out for its advanced capabilities and robust design. This article will explore its features, applications, benefits, and why it is a vital tool in the metalworking industry.

Understanding Roll Forming Technology

Roll forming is a continuous bending operation in which a long strip of metal, typically coiled steel, is fed through consecutive pairs of rolls. Each pair of rolls shapes the metal further until it reaches the desired final profile. Roll forming machines are highly efficient, capable of producing large volumes of components with minimal waste and high consistency.

The T18 20 metal roofing sheet roll forming machine specializes in producing metal roofing sheets, which are known for their durability, weather resistance, and aesthetic appeal. The T18 20 model, in particular, is designed to create trapezoidal profiles that are commonly used in industrial and commercial roofing applications.

Key Features of the T18 20 Machine

1. High-Precision Roll Forming The T18 20 machine incorporates advanced stainless steel rolls, ensuring high precision in the shaping process. This accuracy is crucial for achieving tight tolerances and high-quality finishes on roofing sheets.

2. Robust Construction Built with high-strength steel, the T18 20 is designed to withstand rigorous operational demands, ensuring longevity and reliability in harsh working conditions.

3. User-Friendly Control Panel The machine comes equipped with a PLC (Programmable Logic Controller) for easy operation and monitoring. This feature allows users to set parameters with high accuracy, facilitating quick adjustments and enhancing overall efficiency.

4. Integrated Cutting System The T18 20 includes a hydraulic cutting system that can cut sheets to exact lengths as they exit the roll forming line. This integration minimizes handling and operational delays, allowing for seamless production flow.

5. Versatile Production Capabilities The machine can produce a variety of profiles and thicknesses, making it suitable for diverse applications, from residential roofs to commercial structures.

Applications of the T18 20 Machine

t18 metal roofing sheet roll forming machine

The versatility of the T18 20 metal roofing sheet roll forming machine makes it ideal for various sectors

- Commercial Roofing Its ability to produce durable, lightweight sheets makes it a popular choice among commercial builders looking for cost-effective roofing solutions.

- Agricultural Buildings The machine is widely used in the agricultural sector for constructing barns and storage facilities, where robust and weather-resistant materials are essential.

- Residential Projects Home builders appreciate the aesthetic appeal and durability of metal roofing produced by this machine, making it a preferred option for contemporary homes.

Advantages of Using the T18 20 Metal Roofing Sheet Roll Forming Machine

1. Cost-Effectiveness The high-speed production capabilities of the T18 20 reduce labor costs and material waste, making it a cost-effective solution for manufacturers.

2. Durability Metal roofing is inherently resistant to adverse weather conditions, providing long-lasting solutions that require minimal maintenance.

3. Sustainability Metal roofing is often made from recyclable materials, contributing to environmentally friendly building practices.

4. Aesthetic Flexibility The machine can produce various profiles and finishes, allowing for customization that meets architectural requirements.

5. Enhanced Efficiency With its fast production rates and integrated features, the T18 20 significantly enhances efficiency in manufacturing processes.

Conclusion

The T18 20 metal roofing sheet roll forming machine represents a significant advancement in metalworking technology. Its combination of precision, durability, and efficiency makes it an invaluable asset for manufacturers in the construction sector. As the demand for sustainable and resilient roofing materials continues to grow, investing in a T18 20 machine proves to be a forward-thinking decision for companies aiming to stay competitive in the evolving market. Whether for commercial, agricultural, or residential applications, the T18 20 machine is a cornerstone of modern roofing solutions.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025