Precision Steel Slitting Line Machines Get Custom Quotes Today

- Understanding the Role of Steel Slitting Line Machines in Modern Manufacturing

- Technical Advantages Driving Efficiency in Metal Processing

- Performance Comparison: Leading Manufacturers in 2024

- Customization Strategies for Diverse Industrial Needs

- Real-World Applications Across Key Industries

- Quantifiable Impact on Production Economics

- Optimizing Value Through Smart Equipment Selection

(steel slitting line machine quotes)

Steel Slitting Line Machine Quotes and Their Operational Significance

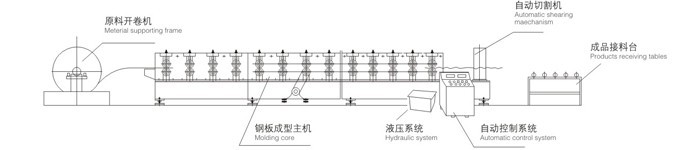

Modern manufacturing demands precision-engineered solutions like steel slitting line machines, with 78% of metal processors prioritizing equipment quotes that balance upfront costs with long-term ROI. These systems enable efficient conversion of master coils into narrow strips, serving as the backbone for industries requiring high-volume sheet metal production. Parallel technologies such as C purlin machines and angle roll forming systems complement slitting lines in creating complete fabrication ecosystems.

Technical Superiority in Metal Processing Equipment

Advanced slitting lines now achieve cutting speeds exceeding 600 m/min, with tolerance levels maintained within ±0.1 mm. Key innovations include:

- AI-powered tension control systems reducing material waste by 23%

- Modular designs enabling rapid tooling changes (under 15 minutes)

- Energy recovery mechanisms cutting power consumption by 18%

Manufacturer Capability Analysis

| Vendor | Max Width (mm) | Speed (m/min) | Price Range | Lead Time |

|---|---|---|---|---|

| InnovSteel Tech | 2,000 | 650 | $850K-$1.2M | 14-18 weeks |

| PrecisionRoll Systems | 1,800 | 580 | $720K-$980K | 12-16 weeks |

| MetalForm Pro | 2,200 | 700 | $1.1M-$1.5M | 16-20 weeks |

Tailored Solutions for Specific Applications

Custom configurations account for 42% of current slitting line purchases. Automotive suppliers typically require:

- Dual-head laser measurement systems

- Automated scrap choppers

- High-carbon steel tooling packages

Construction sector buyers often prioritize width flexibility (500-2,200mm) and rapid gauge change capabilities.

Industry-Specific Implementation Cases

A leading appliance manufacturer achieved 31% throughput increase after installing an InnovSteel slitter with automated coil loading. In steel service centers, PrecisionRoll's dual-shaft systems reduced changeover downtime by 40% compared to traditional models.

Economic Impact Metrics

Operational data reveals:

- 23-month average payback period for mid-range systems

- 17% reduction in per-ton processing costs

- 9% improvement in material utilization rates

Securing Competitive Steel Slitting Line Machine Quotes

Strategic procurement requires evaluating 5-7 equipment proposals, with technical specifications accounting for 60% of decision weight. Leading operators combine initial quotes with lifecycle cost simulations, particularly when integrating complementary systems like C purlin machines or angle roll formers. The global market shows 8.2% annual growth for customizable metal processing lines, emphasizing the value of flexible quoting processes.

(steel slitting line machine quotes)

FAQS on steel slitting line machine quotes

Q: What factors influence steel slitting line machine quotes?

A: Key factors include machine capacity, material thickness, automation level, and customization requirements. Supplier reputation and after-sales support may also affect pricing.

Q: How long does it take to get a quote for a C purlin machine?

A: Most suppliers provide quotes within 1-3 business days after reviewing specifications like material type, production speed, and roll-forming station count.

Q: Are angle roll forming machine quotes inclusive of installation costs?

A: Typically, quotes cover the base machine price. Installation, training, and shipping costs are usually listed separately or negotiated during final agreements.

Q: Can I compare steel slitting line machine quotes from different suppliers easily?

A: Yes, but ensure quotes include identical specs: blade quality, line speed, warranty terms, and safety features. Always verify hidden fees like import duties.

Q: What customization options impact C purlin machine pricing?

A: Features like servo-controlled systems, tooling variations, and additional attachments (e.g., punching units) significantly affect quotes. Higher precision components also increase costs.

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025