roofing sheet roll forming machine

The Benefits and Features of Roofing Sheet Roll Forming Machines

In today's construction industry, the demand for durable, efficient, and cost-effective building materials has led to the popularization of roll forming technology. One of the key players in this field is the roofing sheet roll forming machine, which is revolutionizing how roofing sheets are produced. This innovative machinery offers numerous advantages that appeal to manufacturers and builders alike.

What is a Roofing Sheet Roll Forming Machine?

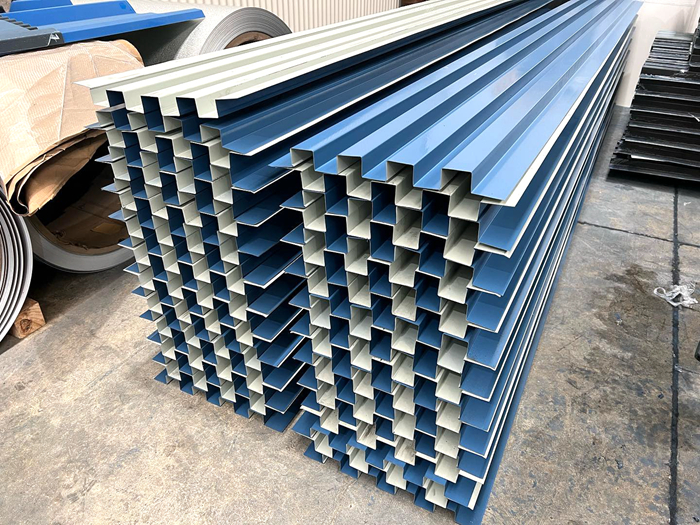

A roofing sheet roll forming machine is specifically designed to produce metal roofing sheets efficiently. The machine uses a continuous bending process to convert flat metal strips, usually galvanized steel, into various roofing profiles. The output sheets can be tailored to meet different design requirements, including various thicknesses, widths, and shapes. This customization capability allows manufacturers to cater to diverse market needs.

Efficiency and Speed

One of the most notable benefits of roofing sheet roll forming machines is their efficiency and speed. Unlike traditional methods of roofing sheet production, which may involve multiple manual processes, roll forming automates the bending and shaping of metal sheets. This reduces production times significantly, allowing manufacturers to meet high demand without compromising on quality. With the ability to produce several meters of roofing material per minute, these machines maximize output and minimize labor costs.

Cost-Effectiveness

Investing in a roofing sheet roll forming machine can lead to substantial cost savings over time. The initial investment is offset by the reduced labor costs and the ability to minimize material waste. Furthermore, roll forming machines often have lower operational costs due to their energy-efficient design. As a result, businesses can enjoy a better return on investment, making it an attractive option for manufacturers.

roofing sheet roll forming machine

Durability and Quality

The roofing sheets produced by roll forming machines are known for their durability and high quality. The process uses high-strength materials that withstand harsh weather conditions, making them ideal for various applications. Whether for residential, commercial, or industrial buildings, these roofing sheets provide excellent structural integrity. Furthermore, the precision of the roll forming process ensures that each sheet is uniformly shaped, delivering a perfect fit when installed.

Versatility of Design

Another significant advantage of roofing sheet roll forming machines is their versatility in design. The machines can be configured to produce an array of profiles, including corrugated, trapezoidal, and standing seam roofing. This adaptability allows manufacturers to switch between designs quickly, catering to specific project requirements without the need for extensive retooling. Additionally, manufacturers can create customized profiles that reflect current architectural trends, giving their clients a competitive edge in the market.

Environmental Benefits

In an era where sustainability is paramount, roofing sheet roll forming machines provide ecological benefits. The production process generates minimal waste, as excess material can often be recycled back into the manufacturing line. Furthermore, many roofing sheets produced are made from recyclable materials, promoting a circular economy approach.

Conclusion

In conclusion, roofing sheet roll forming machines represent a significant advancement in the production of roofing materials. Their efficiency, cost-effectiveness, durability, and versatility make them a preferred choice for manufacturers in the construction sector. As the demand for high-quality roofing materials continues to grow, embracing this innovative technology can provide businesses with a competitive advantage, ensuring they meet the evolving needs of their customers while also contributing to a more sustainable future. Whether for new construction or renovation projects, roofing sheet roll forming machines are paving the way for the future of roofing solutions.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025