Mar . 06, 2025 13:01

Back to list

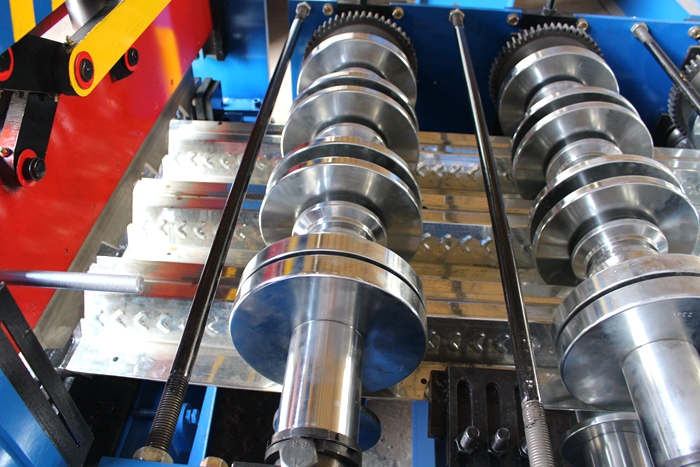

roll forming machine for sheet metal

The roll forming machine for sheet metal has become an essential element in the modern manufacturing landscape, offering unrivaled efficiency and precision for metalworking processes. Unlike traditional machine tools, these specially designed roll forming machines are engineered to handle a variety of metals, including steel, aluminum, and copper, transforming simple sheets into complex profiles with consistent quality and dimensional accuracy.

Authoritative understanding comes into play with the adaptability of roll forming machines to meet diverse manufacturing challenges. With custom die tooling, a roll forming machine can be configured to produce complex cross-sections that are otherwise difficult to achieve with traditional methods. This capability is invaluable for industries like automotive, construction, and aerospace, where precision components are non-negotiable. Trustworthiness is demonstrated by the machine manufacturers who not only provide state-of-the-art equipment but also offer robust after-sales support. Reliable suppliers invest in customer education, offering training and comprehensive documentation to empower operators. Furthermore, they ensure their machines comply with international standards, which not only guarantees safety and environmental considerations but also maximizes operational efficiency. In conclusion, the roll forming machine for sheet metal fabrication exemplifies technological advancement in the manufacturing domain. Its precision, efficiency, and adaptability distinguish it as a superior choice for high-volume production with complex profile requirements. By combining experience, expertise, authoritative guidance, and trustworthiness, businesses can optimize their metal forming processes, leading to enhanced product quality and competitiveness in the global market. Whether incorporating advanced materials or custom configurations, roll forming remains an unparalleled method for meeting sophisticated engineering and manufacturing demands.

Authoritative understanding comes into play with the adaptability of roll forming machines to meet diverse manufacturing challenges. With custom die tooling, a roll forming machine can be configured to produce complex cross-sections that are otherwise difficult to achieve with traditional methods. This capability is invaluable for industries like automotive, construction, and aerospace, where precision components are non-negotiable. Trustworthiness is demonstrated by the machine manufacturers who not only provide state-of-the-art equipment but also offer robust after-sales support. Reliable suppliers invest in customer education, offering training and comprehensive documentation to empower operators. Furthermore, they ensure their machines comply with international standards, which not only guarantees safety and environmental considerations but also maximizes operational efficiency. In conclusion, the roll forming machine for sheet metal fabrication exemplifies technological advancement in the manufacturing domain. Its precision, efficiency, and adaptability distinguish it as a superior choice for high-volume production with complex profile requirements. By combining experience, expertise, authoritative guidance, and trustworthiness, businesses can optimize their metal forming processes, leading to enhanced product quality and competitiveness in the global market. Whether incorporating advanced materials or custom configurations, roll forming remains an unparalleled method for meeting sophisticated engineering and manufacturing demands.

Latest news

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

Related Products