Production Equipment for High-Quality Zinc Sheet Manufacturing and Forming Processes in Factories

The Evolution and Importance of Zinc Sheet Making Machines in Modern Manufacturing

In the realm of industrial manufacturing, zinc sheets play a crucial role by providing a robust solution for various applications, including roofing, automotive components, and construction materials. The demand for high-quality zinc sheets has surged in recent years, necessitating the development of advanced machinery tailored for their production. One such advancement is the zinc sheet making machine, a vital piece of equipment in factories dedicated to producing zinc-coated sheets.

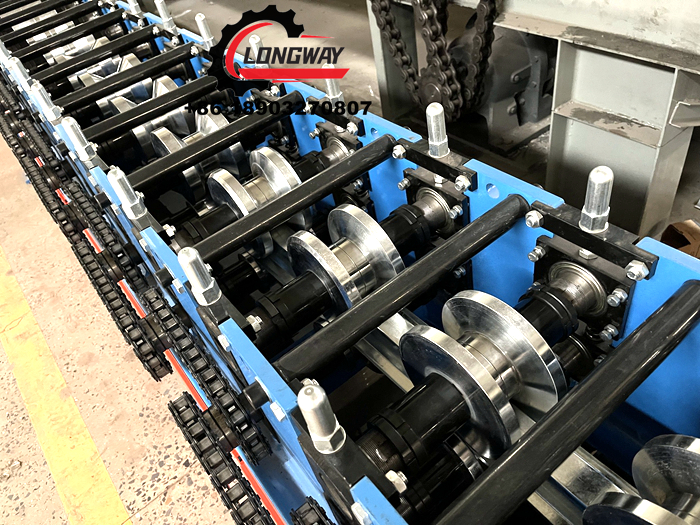

Zinc sheet making machines are engineering marvels designed to streamline the manufacturing process of galvanized steel products. These machines are capable of producing sheets of variable thickness and width, meeting the diverse needs of industries worldwide. The technology has evolved significantly, incorporating automation and precision engineering to enhance productivity and quality control.

The primary process involved in zinc sheet production is galvanization, where a thin layer of zinc is applied to steel sheets to prevent corrosion. This process not only extends the lifespan of the steel but also enhances its aesthetic appeal. Zinc sheet making machines use several techniques, including hot-dip galvanization and electro-galvanization. Hot-dip galvanization involves submerging the steel sheets in molten zinc, allowing for a thicker, more durable coating. In contrast, electro-galvanization uses electrical current to deposit a thin layer of zinc, offering a finer finish suitable for applications requiring less corrosion resistance.

The design of zinc sheet making machines incorporates various features to ensure operational efficiency. Advanced control systems allow for precise adjustments to thickness and coating weight, ensuring that each sheet meets specific industry standards. Moreover, improved cooling systems in these machines prevent overheating, enhancing their longevity and reducing maintenance costs.

zinc sheet making machine factory

One of the notable trends in the production of zinc sheets is the integration of eco-friendly practices. Modern machines are designed to minimize waste and energy consumption. Operators are increasingly looking for machines that utilize less water and energy during the galvanization process. By adopting such environmentally friendly practices, manufacturers not only reduce their carbon footprint but also comply with stringent environmental regulations.

Another significant aspect of zinc sheet production is the increasing emphasis on quality. Zinc sheet making machines are equipped with advanced monitoring systems that assess the quality of the output in real time. These systems measure various parameters, from the thickness of the zinc coating to the overall surface finish, ensuring that the final product meets the highest standards. This level of quality control is essential as industries become more reliant on consistent and durable materials.

As industries continue to evolve, the demand for zinc sheets is expected to grow. From construction to automotive applications, the versatility of zinc-coated materials positions them as a preferred choice for manufacturers. Consequently, investing in state-of-the-art zinc sheet making machines is not just an option; it is a necessity for factories that aim to remain competitive in a dynamic market.

In conclusion, the zinc sheet making machine factory plays a pivotal role in the production of high-quality zinc sheets, essential for various industries. With advancements in technology, focus on sustainability, and an unwavering commitment to quality, these machines are at the forefront of modern manufacturing. As the industry continues to grow, the importance of zinc sheet making machines will undoubtedly increase, driving innovation and efficiency in the production process. Through continuous improvements, manufacturers will meet the evolving demands of the market while contributing to a more sustainable future.

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025