metal roofing roll forming machines for sale manufacturer

Metal Roofing Roll Forming Machines for Sale A Comprehensive Look at Manufacturers

In today’s construction and manufacturing landscape, metal roofing has emerged as a popular choice due to its durability, sustainability, and aesthetic appeal. The production of metal roofing panels is facilitated by specialized machinery known as roll forming machines. These machines play a vital role in producing high-quality metal roofing materials efficiently and at scale. With a plethora of manufacturers in the market, it's essential to understand what to look for when considering the purchase of metal roofing roll forming machines.

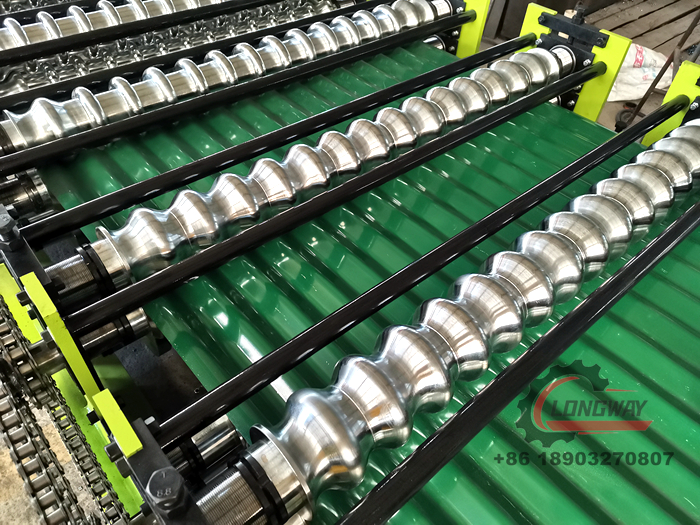

Understanding Roll Forming Machines

Roll forming is a process that involves the continuous bending of a long strip of metal into desired cross-sectional profiles. This is achieved by passing the metal sheet through a series of rollers, each designed to shape the material progressively until it reaches the final profile. Metal roofing roll forming machines are specifically engineered to produce various styles of roofing panels, such as standing seam, corrugated, and shingles.

The primary advantages of using roll forming machines include

1. Efficiency Once set up, these machines can operate continuously, producing long lengths of roofing material without interruption. 2. Consistency Roll forming ensures uniformity in the dimensions and quality of the roofing panels, which is critical for both aesthetics and structural integrity. 3. Material Utilization Roll forming minimizes waste, as the process is designed to use only the necessary amount of raw material. 4. Versatility Many machines are designed to produce multiple profiles, offering manufacturers the flexibility to meet varying market demands.

Key Features to Look For

When exploring manufacturers for metal roofing roll forming machines, several critical features should be considered

1. Quality of Construction Durable machines built with high-quality materials not only withstand the demands of production but also require less maintenance over time. Look for manufacturers who use robust steel and proven engineering practices.

metal roofing roll forming machines for sale manufacturer

2. Customization Options The ability to customize the machine to produce specific profiles or accommodate different materials (such as Galvalume, copper, or aluminum) is a significant advantage. Many manufacturers offer tailored solutions to meet the unique needs of their clientele.

3. Ease of Operation User-friendly controls and automation features can greatly enhance productivity. Machines with advanced technology, such as touch-screen interfaces and programmable settings, also reduce the likelihood of human error.

4. Support and Maintenance A reliable manufacturer should provide comprehensive after-sales support, including installation assistance, operator training, and access to replacement parts. This is essential for minimizing downtime and ensuring long-term operational success.

5. Warranty and Guarantees A solid warranty reflects the manufacturer's confidence in their product. Look for machines that come with extensive warranties, protecting your investment against defects and operational failures.

Leading Manufacturers in the Market

Several manufacturers have established themselves as leaders in producing metal roofing roll forming machines. Companies such as Winstar, Bemo, and Harris Products are renowned for their cutting-edge technology and commitment to quality. Each company offers a diverse range of models with varying specifications to cater to different production needs.

Winstar, for instance, is known for its innovative features, such as high-speed production capabilities and energy-efficient designs, making it a favorite among large-scale manufacturers. Bemo focuses on producing highly customized solutions to meet the specific requirements of the roofing industry, while Harris Products emphasizes user-friendly designs, allowing for easy operation.

Conclusion

Investing in a metal roofing roll forming machine is a significant decision for any manufacturer in the roofing industry. The right machine can enhance production efficiency, improve product quality, and ultimately contribute to the success of your business. By considering key features and options available from reputable manufacturers, businesses can ensure they are making a well-informed choice. As the demand for metal roofing continues to rise, having the right machinery will position manufacturers to thrive in a competitive market. Choose wisely, and watch your production capabilities soar with the right metal roofing roll forming machine.

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025