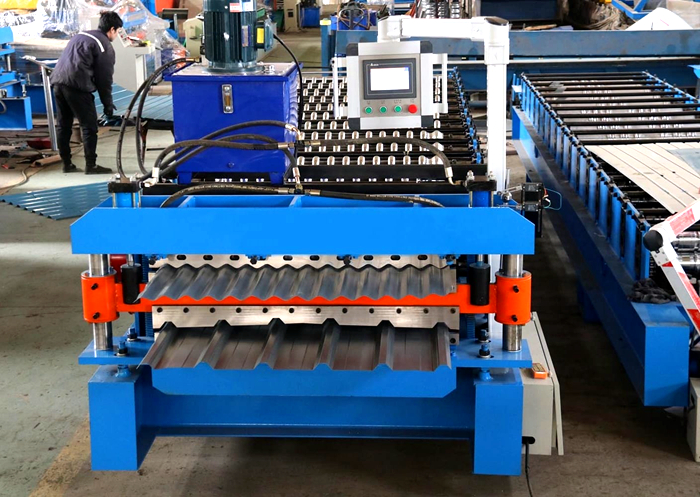

metal double layer roll forming machine

Metal Double Layer Roll Forming Machine A Comprehensive Overview

In the ever-evolving world of manufacturing, efficiency, innovation, and quality are paramount. One of the technological marvels that embodies these principles is the metal double layer roll forming machine. This advanced piece of equipment combines versatility with precision, allowing manufacturers to produce a wide range of metal products with remarkable speed and accuracy.

The metal double layer roll forming machine is designed to create two different profiles with a single production line, effectively doubling productivity without the need for additional machinery. This dual functionality is achieved through the use of two separate sets of roll forming stations, which operate simultaneously. As a result, manufacturers can produce various products such as roofing sheets, wall panels, and even structural components, all from the same machine. This flexibility not only saves space in the production area but also reduces overall operational costs.

One of the primary advantages of the metal double layer roll forming machine is its ability to utilize a variety of raw materials

. It can work with different types of metal sheets, such as galvanized steel, aluminum, and stainless steel, catering to diverse customer needs and industry requirements. The machine's adjustable parameters allow operators to change the specifications easily, ensuring consistent product quality without significant downtime.metal double layer roll forming machine

Moreover, this type of roll forming machine is equipped with state-of-the-art technology that enhances accuracy and efficiency. Computer Numerical Control (CNC) systems are often integrated into these machines, providing precise control over the forming process. This technology enables operators to program specific designs and dimensions, ensuring that every product meets exact specifications. Additionally, with automatic feeding and cutting systems, production is streamlined, minimizing human error and further increasing output.

Maintenance and operation of the metal double layer roll forming machine are relatively user-friendly. Manufacturers can rely on robust construction and high-quality materials that ensure longevity and durability. Regular maintenance schedules can be easily established to keep the machine running smoothly, reducing the likelihood of unexpected breakdowns or production delays. This reliability is crucial in today’s fast-paced manufacturing environment, where time is money.

Safety is another critical aspect when it comes to operating the metal double layer roll forming machine. Modern machines are built with various safety features, including emergency stop buttons, protective covers, and safety sensors. These safety measures are crucial for protecting operators and ensuring a safe working environment.

In conclusion, the metal double layer roll forming machine represents a significant advancement in metal manufacturing technology. Its ability to produce multiple profiles concurrently, coupled with its versatility in handling different materials, makes it an essential tool for businesses looking to enhance their production capabilities. As industries continue to demand higher efficiency and quality, investing in such advanced machinery will be a game-changer for manufacturers seeking to remain competitive in the market. Whether for large-scale production or specialized applications, the metal double layer roll forming machine stands out as a reliable and efficient solution in the modern manufacturing landscape.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025