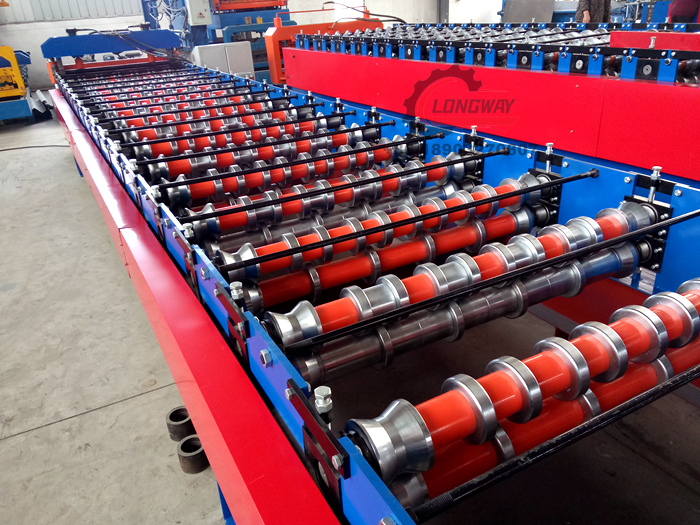

light gauge steel framing roll forming machine

The Advantages of Light Gauge Steel Framing Roll Forming Machines

In the modern construction industry, the demand for efficient, durable, and cost-effective materials has led to an increased interest in light gauge steel framing. This innovative approach utilizes thin sheets of steel that are roll-formed into structural components, providing numerous benefits over traditional building materials. At the heart of this process are light gauge steel framing roll forming machines, which play a crucial role in manufacturing the essential components of light gauge steel structures.

Light gauge steel framing is characterized by its lightweight yet strong design, making it an ideal choice for various construction applications, from residential buildings to commercial structures. These machines are engineered to produce steel sections with precise dimensions, ensuring consistency and high-quality output. This precision is essential for maintaining the structural integrity of buildings, allowing for quick assembly and reduced waste, which is a significant advantage in today’s environmentally conscious market.

One of the primary benefits of using roll forming machines for light gauge steel framing is efficiency. The machines are designed to operate at high speeds, significantly reducing production time. This efficiency is critical for builders and contractors who need to meet tight deadlines in competitive markets. Furthermore, the automated nature of these machines minimizes labor costs, as fewer workers are needed to oversee the production process.

light gauge steel framing roll forming machine

In addition to efficiency, light gauge steel framing roll forming machines contribute to material optimization. Traditionally, building materials can result in excess waste due to cutting and shaping. However, roll forming allows for continuous lengths of steel to be shaped into required profiles without the need for cutting, thereby maximizing the material usage. This aspect is particularly important in efforts to reduce the environmental footprint of construction projects. By minimizing waste, companies can not only save costs but also appeal to the growing segment of environmentally conscious consumers.

Durability is another key attribute of light gauge steel framing. Steel is inherently resistant to many issues that can affect traditional materials, such as rot, mold, and pest infestation. Buildings constructed using light gauge steel frameworks tend to have a longer lifespan and require less maintenance over time. This durability is particularly advantageous in various climates, as steel can withstand harsh weather conditions better than other materials.

Moreover, the versatility of light gauge steel framing allows for a wide range of architectural designs. The flexibility of steel means that it can be formed into intricate shapes and sizes, accommodating the unique requirements of any project. This adaptability makes it a favorite among architects and engineers looking to push the boundaries of design while still ensuring safety and structural integrity.

In conclusion, light gauge steel framing roll forming machines have revolutionized the construction industry by providing an efficient, durable, and environmentally friendly solution for building frameworks. As the industry continues to evolve, these machines will play an increasingly vital role in shaping the future of construction, helping to meet the demands of modern architecture while promoting sustainability and cost-effective building practices. The integration of this technology not only enhances productivity but also contributes to the development of safer and more resilient structures in our communities.

-

Understanding Steel Coil Cutting Machines and Their ImportanceNewsMay.16, 2025

-

The Essential Guide to Floor Deck Roll Forming MachinesNewsMay.16, 2025

-

Slitting Lines and Their BenefitsNewsMay.16, 2025

-

Sheet Metal Slitting Machines and Their OptionsNewsMay.16, 2025

-

Choosing the Best Downpipe Roll Forming MachinesNewsMay.16, 2025

-

5 Inch Gutter Machines: The Key to Efficient Gutter ProductionNewsMay.16, 2025

-

The Latest Trends in Cut to Length Equipment and MachinesNewsMay.09, 2025