IBR Roof Sheet Production Equipment for Efficient Roofing Solutions

The IBR Roof Sheet Forming Machine Revolutionizing Roofing Solutions

In the construction and roofing industry, efficiency and quality are paramount. One of the standout innovations in this field is the IBR roof sheet forming machine, a technology designed to streamline the production of high-quality roofing sheets. The popularity of IBR (Inverted Box Rib) sheets can be attributed to their durability, aesthetic appeal, and cost-effectiveness, making them a preferred choice for both residential and commercial buildings.

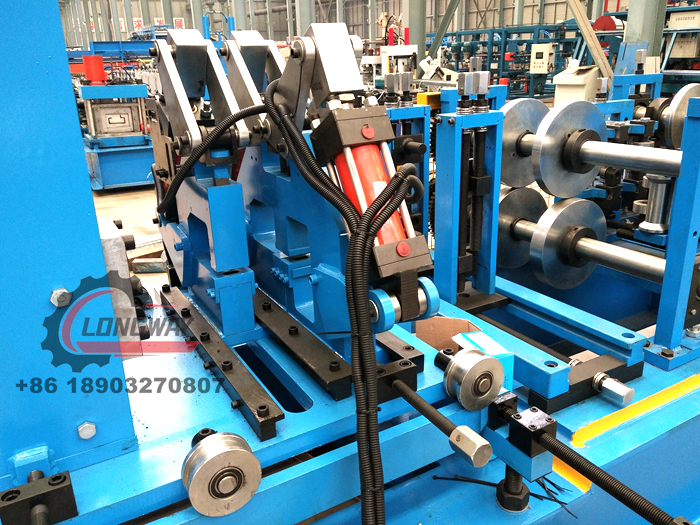

The IBR roof sheet forming machine automates the manufacturing process, allowing for quick and efficient production of roofing sheets shaped in the unique IBR profile. This profile features distinct ribs that enhance the strength of the sheets while also providing a modern aesthetic. The machine operates through a series of rollers that shape flat metal sheets into the desired form. The ability to produce these sheets on-site reduces lead times and minimizes waste, making it an ideal solution for contractors and builders who require timely project completion.

The IBR Roof Sheet Forming Machine Revolutionizing Roofing Solutions

Moreover, the IBR roof sheet forming machine is designed with energy efficiency in mind. Modern machines are equipped with features that minimize power consumption without compromising output quality. This not only reduces operational costs for manufacturers but also aligns with the increasing global emphasis on sustainability in construction practices. By reducing energy usage during production, these machines contribute to environmentally friendly building solutions.

ibr roof sheet forming machine

Maintenance plays a vital role in the longevity and efficiency of the IBR roof sheet forming machine. Regular upkeep ensures that the machine operates at optimal levels, producing high-quality sheets consistently. Many manufacturers offer comprehensive service packages that include training for operators, spare parts supply, and technical support to ensure that users get the most out of their investment.

As the demand for roofing solutions continues to grow, particularly in emerging markets, IBR roof sheet forming machines have become essential tools for manufacturers aiming to stay competitive. Companies leveraging this technology not only meet the demand for quality roofing materials but also enhance their production capabilities and respond swiftly to market changes.

The future of roofing production looks promising with the ongoing advancements in forming machine technology. Innovations such as automation, smart controls, and AI integration are expected to further enhance the productivity and efficiency of IBR roof sheet forming machines, paving the way for even more superior roofing solutions.

In conclusion, the IBR roof sheet forming machine represents a significant advancement in the construction industry. By offering high-quality, efficient, and sustainable roofing solutions, it supports builders in meeting the evolving demands of the market while ensuring that projects can be completed on time and within budget. Investing in this technology is not just about keeping up with the current trends; it is a strategic move toward a more efficient and sustainable future in construction.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025