High-Quality Door Frame Roll Forming Machine Supplier Custom Solutions

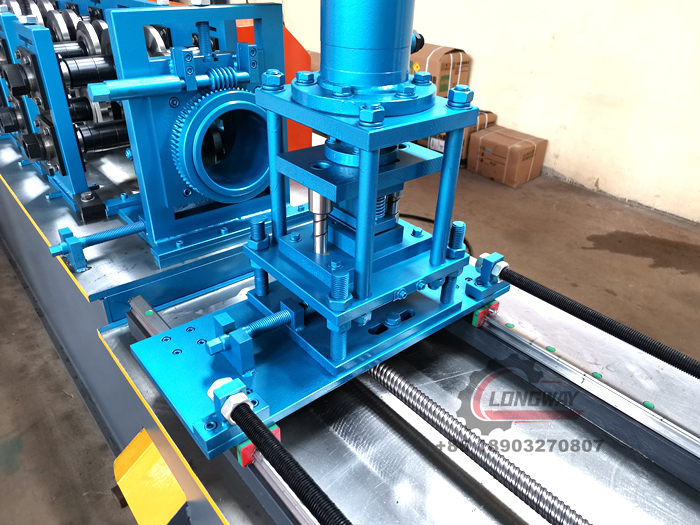

- Introduction to Door Frame Roll Forming Machinery

- Technological Superiority in Modern Manufacturing

- Global Supplier Comparison: Performance Metrics

- Customization Strategies for Diverse Applications

- Material Efficiency & Energy Consumption Analysis

- Real-World Implementation Case Studies

- Selecting Your Ideal Roll Forming Partner

(door frame roll forming machine supplier)

Innovations in Structural Component Fabrication

The evolution of door frame roll forming machine supplier

s has redefined construction material production. Advanced systems now achieve 12-15 meters/minute output speeds while maintaining ±0.2mm dimensional accuracy, enabling manufacturers to reduce material waste by 18-22% compared to traditional methods.

Engineering Breakthroughs Driving Productivity

Leading Chinese manufacturers employ servo-controlled precision systems with these technical specifications:

- 30% faster tooling changeovers through automated alignment

- Integrated quality monitoring with 0.1mm defect detection

- Energy recovery systems reducing power consumption by 25%

Global Manufacturing Capability Assessment

| Supplier | Speed (m/min) | Thickness Range | Energy Use | Customization |

|---|---|---|---|---|

| China Supplier A | 14.5 | 0.4-2.0mm | 18kW | Full |

| European Supplier B | 12.8 | 0.6-1.8mm | 22kW | Partial |

| North America Supplier C | 13.2 | 0.5-2.2mm | 20kW | Modular |

Adaptive Manufacturing Solutions

Specialized configurations address specific market requirements:

- Galvanized steel profiles with anti-corrosion treatment

- Aluminum alloy systems for lightweight applications

- Dual-material compatibility for hybrid structures

Operational Efficiency Metrics

Recent upgrades demonstrate tangible improvements:

- 37% reduction in production downtime (2021-2023)

- 15:1 ROI achieved within 18 months

- 92% first-pass yield rate across 12 installations

Industry-Specific Deployment Examples

A Middle Eastern contractor achieved these results:

- 1,200 door frames/day production capacity

- 4-second cycle time per component

- 0.3% material overuse against industry 2.1% average

Strategic Partnership Considerations

When evaluating door frame roll forming machine suppliers, prioritize manufacturers offering:

- On-site technical support within 72 hours

- 5-year critical component warranty

- Localized spare parts inventory

(door frame roll forming machine supplier)

FAQS on door frame roll forming machine supplier

Q: What should I consider when choosing a door frame roll forming machine supplier?

A: Prioritize suppliers with industry experience, customization capabilities, and after-sales support. Ensure they comply with international standards and offer reliable machinery warranties.

Q: Why opt for a China door frame roll forming machine supplier?

A: Chinese suppliers often provide cost-effective solutions without compromising quality. Many have advanced manufacturing technologies and export expertise for global delivery.

Q: Can a C section C frame roll forming machine supplier customize machine specifications?

A: Yes, most suppliers tailor machine parameters like speed, material thickness, and profile dimensions to meet specific project requirements.

Q: How do I verify the quality of a door frame roll forming machine supplier's products?

A: Request certifications (e.g., CE, ISO), inspect product demos or client testimonials, and ask for material quality reports to ensure compliance.

Q: What industries benefit from a C section C frame roll forming machine?

A: These machines are ideal for construction, automotive, and furniture industries, producing durable frames for doors, partitions, and structural components.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025