Custom Roll Forming Machine for Unique Trapezoidal Profiles and Efficient Production Solutions

Custom Trapezoidal Roll Forming Machine Revolutionizing the Metal Fabrication Industry

In an era where precision engineering and high efficiency are paramount, the demand for custom machinery has surged. One of the notable innovations in this realm is the custom trapezoidal roll forming machine. This specialized equipment is engineered to produce trapezoidal sheets and profiles that are widely used in construction, roofing, and various industrial applications.

Understanding Trapezoidal Roll Forming

Roll forming is a continuous bending operation in which a long strip of metal is gradually shaped into a desired cross-sectional profile. The trapezoidal design, characterized by two parallel sides and two non-parallel sides, offers an optimal combination of strength, stability, and aesthetic appeal. It is particularly favored in roofing systems due to its ability to channel water effectively and reduce accumulation, thereby preventing leaks.

Custom trapezoidal roll forming machines are tailored to meet the specific requirements of manufacturers. They allow for the production of profiles with varying dimensions, materials, and thicknesses, making them ideal for diverse applications. These machines can process various metals, including steel, aluminum, and copper, ensuring versatility in production lines.

Benefits of Customization

One of the significant advantages of a custom trapezoidal roll forming machine is the ability to streamline production processes. Manufacturers can design their roll forming equipment to accommodate specific profiles they frequently require, reducing downtime and enhancing productivity. This customization enables companies to respond swiftly to market demands, optimizing the supply chain and minimizing waste.

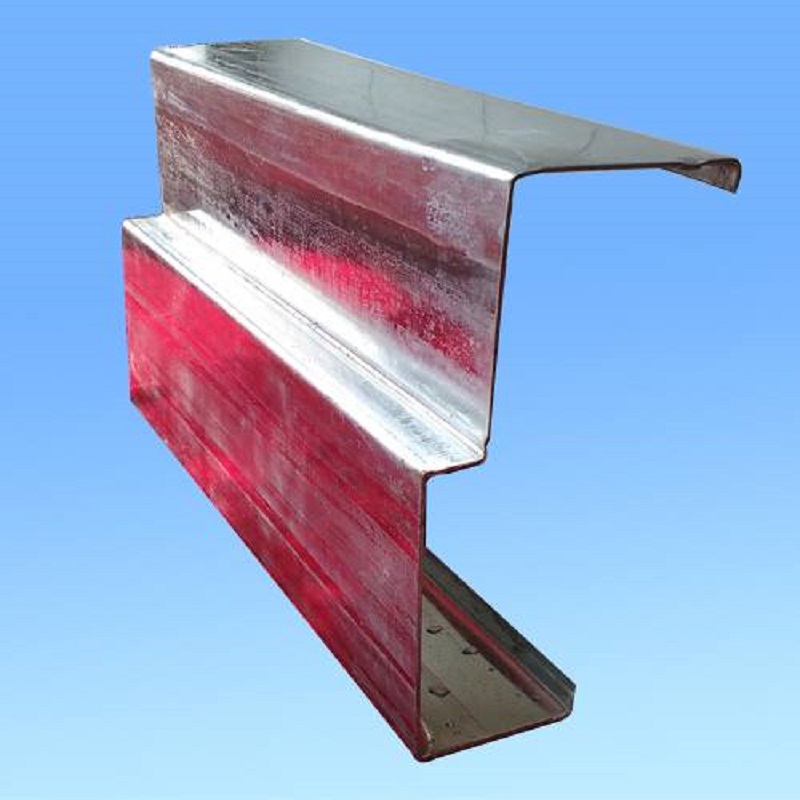

custom trapezoidal roll forming machine

Moreover, the precision of a well-designed roll forming machine ensures consistency in product quality. The processes involved eliminate human errors often found in traditional manufacturing methods, resulting in uniform profiles that meet exact specifications. Such accuracy is crucial in construction, where structural integrity heavily relies on precise components.

Enhanced Efficiency and Cost-Effectiveness

Investing in a custom trapezoidal roll forming machine can also lead to significant cost savings in the long run. Automated systems reduce labor costs and increase output speeds, allowing businesses to meet high demand without compromising on quality. Additionally, the ability to use multiple metal types means that manufacturers can choose the most cost-effective materials for their specific products.

The setup and maintenance of these machines have also evolved with technological advancements. Most modern roll forming machines come equipped with user-friendly interfaces and diagnostic tools that simplify operations and routine checks, thus reducing downtime and the need for extensive training.

Conclusion

In summary, the custom trapezoidal roll forming machine stands out as a vital innovation in the metal fabrication industry. By enabling manufacturers to produce high-quality trapezoidal profiles efficiently, these machines not only enhance productivity but also allow for significant customization tailored to unique operational needs. As industries continue to evolve and demand for tailored solutions grows, the relevance of custom trapezoidal roll forming machines will undoubtedly increase. Embracing this technology will position manufacturers at the forefront of their industries, ready to tackle the challenges of tomorrow.

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025