custom rollformers

Understanding Custom Rollformers A Key Solution for Modern Manufacturing

In the evolving landscape of manufacturing, the need for precision, efficiency, and adaptability is paramount. At the forefront of these manufacturing needs are custom rollformers, innovative machines that streamline the production of metal products and components. Understanding the intricacies of custom rollformers can provide significant insights into their capabilities, benefits, and applications in various industries.

What are Custom Rollformers?

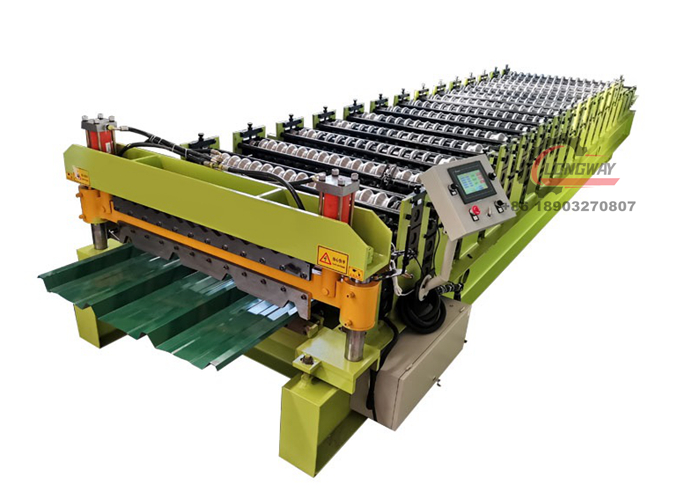

Custom rollformers are specialized machinery designed to transform flat metal sheets into specific profiles through a continuous bending process. Unlike traditional methods that can be time-consuming and labor-intensive, custom rollforming offers a highly efficient way to create complex shapes with precision. These machines can be tailored according to the unique specifications of a project, allowing manufacturers to produce a wide variety of components, from simple brackets to intricate architectural features.

The Rollforming Process

The rollforming process begins with a flat metal strip, usually made of steel, aluminum, or another malleable material, which is fed through a series of rollers. Each roller is strategically designed to gradually shape the metal as it passes through, creating a desired profile in a continuous motion. The beauty of this process lies in its capability to produce lengthy parts with consistent cross-sections, minimizing waste and maximizing material yield.

Benefits of Custom Rollformers

1. Precision and Consistency One of the primary advantages of custom rollformers is their ability to maintain high precision and consistent quality throughout production. The automated nature of these machines ensures that every piece produced meets strict specifications, reducing the risk of errors and rework.

custom rollformers

2. Cost-Effectiveness While the initial investment in custom rollforming equipment may be substantial, the long-term savings can be significant. The efficiency of the rollforming process translates into lower labor costs and reduced material waste. Additionally, the speed of production allows manufacturers to meet demand quickly, further contributing to cost savings.

3. Flexibility and Customization Custom rollformers are inherently adaptable, allowing manufacturers to tailor designs to specific project requirements. Whether a company needs a unique profile for a building project or a standard shape for everyday applications, custom rollformers can be configured to meet those needs.

4. Scalability As production needs grow, custom rollformers can scale up operations without a significant increase in overhead costs. This scalability makes them an attractive option for manufacturers looking to expand their capabilities or enter new markets.

Applications in Various Industries

The versatility of custom rollformers opens doors to numerous applications across various industries. In the construction and architecture sectors, rollformed components are used extensively for roofing, siding, and framing. The automotive industry benefits from rollformed parts for structural components, while the HVAC industry utilizes them for ductwork and ventilation systems. Additionally, custom rollformers are integral to producing components for machinery, furniture, and even consumer electronics.

Conclusion

In conclusion, custom rollformers represent a crucial advancement in manufacturing technology. Their ability to create high-quality, custom metal profiles with speed and efficiency is transforming how industries approach production. As businesses continue to seek ways to enhance their operations and meet the demands of an ever-changing market, investing in custom rollforming technology becomes increasingly advantageous. Understanding this innovative solution is essential for manufacturers aiming to stay competitive in today’s dynamic industrial landscape. By embracing the capabilities of custom rollformers, businesses can not only streamline their manufacturing processes but also pave the way for future growth and innovation.

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025