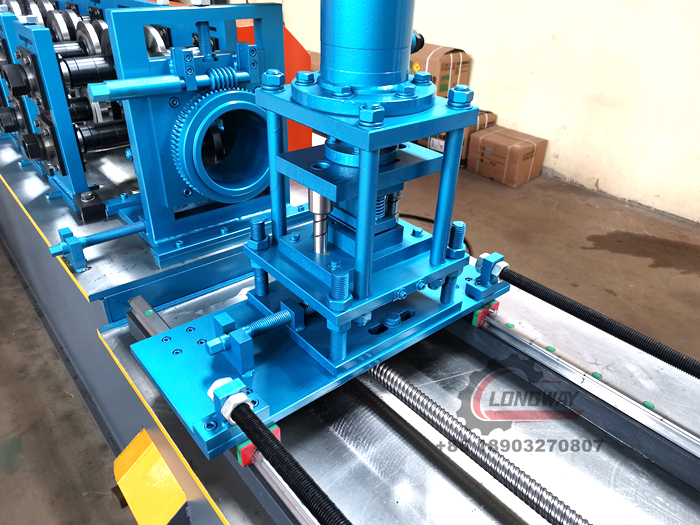

custom double layer roofing sheet roll forming machine

Custom Double Layer Roofing Sheet Roll Forming Machine An Overview

In the modern construction industry, the demand for efficient and versatile roofing solutions has led to significant advancements in manufacturing technologies. One such innovation is the custom double layer roofing sheet roll forming machine. This equipment is designed to produce roofing sheets with two distinct profiles within a single pass, maximizing efficiency and minimizing waste.

A double layer roofing sheet roll forming machine operates by utilizing two sets of tooling that form the sheets simultaneously. This design allows manufacturers to produce two different types of roofing sheets, such as corrugated and tile profiles, on the same machine. This versatility is particularly beneficial for businesses looking to diversify their product offerings without the need for multiple machines.

The key advantages of using a double layer roll forming machine are cost efficiency, space-saving, and increased productivity. By producing two types of sheets in one operation, manufacturers can reduce labor and operational costs. Additionally, a dual-layer machine occupies less floor space, making it an ideal choice for smaller factories with limited room for equipment.

custom double layer roofing sheet roll forming machine

Customization is a critical aspect of today’s manufacturing processes. A custom double layer roofing sheet roll forming machine can be tailored to meet the specific needs of any project. Customers can choose the material, thickness, and coating of the sheets produced. Common materials include galvanized steel, aluminum, and color-coated sheets, enabling the production of roofing materials suitable for a variety of environmental conditions and aesthetic preferences.

The machines are also equipped with advanced control systems that ensure precise dimensions and consistent quality throughout the production run. Many models feature PLC (Programmable Logic Controller) technology that allows for easy operation, monitoring, and adjustment of speeds and settings. Optional features such as automatic cut-to-length systems and other automated processes further enhance efficiency.

Furthermore, the demand for sustainable construction materials is driving innovations in roofing solutions. Manufacturers of double layer roofing sheet roll forming machines are increasingly integrating eco-friendly practices into their operations. This includes utilizing recyclable materials and adopting energy-efficient technologies that reduce the overall carbon footprint of the manufacturing process.

In conclusion, the custom double layer roofing sheet roll forming machine represents a significant advancement in roofing material production. Its ability to produce multiple profiles in a single operation not only enhances productivity but also offers manufacturers the flexibility to adapt to market demands. As the construction industry continues to evolve, investing in such innovative machinery will be essential for businesses aiming to stay competitive while meeting the diverse needs of their customers. Embracing these technologies ensures that manufacturers can deliver high-quality, aesthetically pleasing, and environmentally friendly roofing solutions, ultimately contributing to the growth and sustainability of the construction sector.

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025