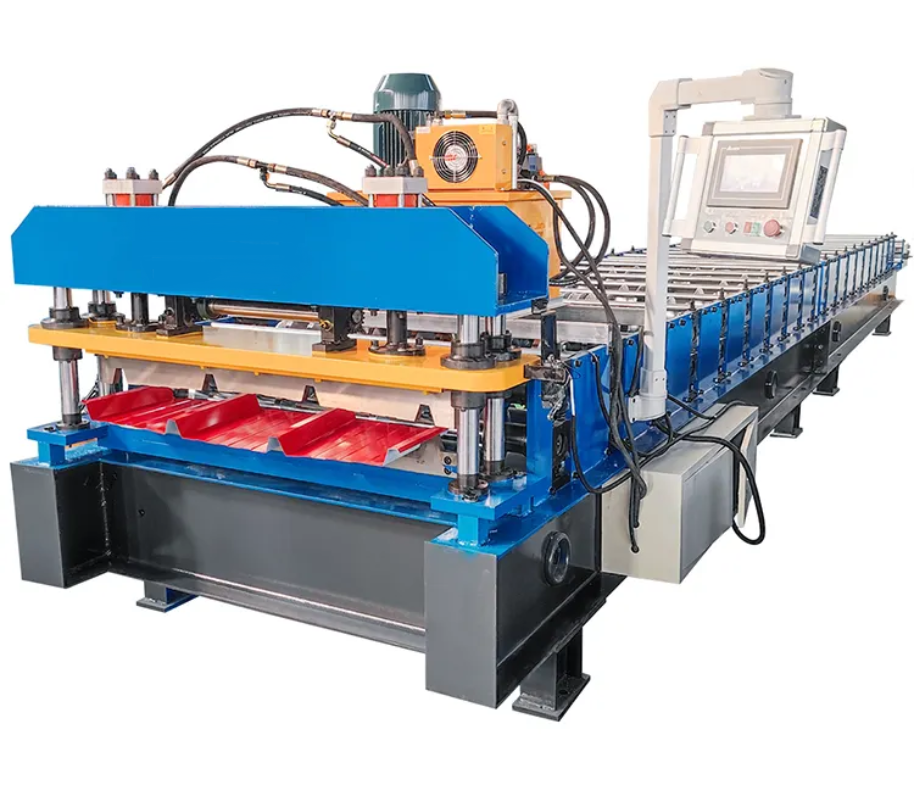

custom roofing roll former

Custom Roofing Roll Former Enhancing Efficiency and Quality in Roof Manufacturing

In the world of roofing, efficiency, precision, and quality are paramount. Custom roofing roll formers have emerged as essential tools in the manufacturing process, allowing companies to produce roofing materials that meet specific customer requirements. These machines combine advanced technology with flexibility, facilitating the production of a wide variety of roofing profiles, sizes, and materials.

A roofing roll former is a machine that manufactures metal roofing panels by forming sheets of metal into specific shapes. The process involves feeding a flat metal sheet through a series of rollers that gradually shape it into the desired profile. Custom roofing roll formers are designed to accommodate different types of roofing profiles, including standing seam, corrugated, and shingles, making them ideal for businesses that cater to diverse roofing needs.

One of the most significant advantages of a custom roll former is its ability to produce materials on-demand. Traditional manufacturing methods often involve long lead times and significant inventory costs. However, with a custom roll former, manufacturers can quickly switch between different profiles and sizes as needed. This adaptability not only reduces waste but also allows companies to respond more swiftly to market demands and customer preferences.

custom roofing roll former

Moreover, these machines offer enhanced precision. The use of computer numerical control (CNC) technology in modern roll formers ensures that every panel produced meets strict specifications. This level of accuracy minimizes errors and provides consistent quality across all products. As a result, roofing contractors can trust that the materials they receive will fit perfectly and perform optimally when installed.

Customization is another key feature of modern roofing roll formers. Manufacturers can tailor their machines to produce specific profiles that cater to unique architectural designs or regional styles. This capability allows roofing companies to differentiate themselves in a competitive market by offering exclusive products that stand out in terms of aesthetics and functionality.

Additionally, investing in a custom roofing roll former can lead to long-term cost savings

. While the initial investment may be substantial, the reduction in labor costs, waste, and inventory expenses typically pays off quickly. Companies can achieve a quicker return on investment while also improving their production capacity and turnaround times.In conclusion, custom roofing roll formers are revolutionizing the roofing industry by enhancing efficiency, precision, and customization. As manufacturers continue to seek ways to innovate and meet the evolving demands of the market, these machines will play an increasingly vital role in producing high-quality roofing materials. By adopting this technology, companies can not only improve their operational efficiency but also deliver superior products that meet their clients’ unique needs.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025