Custom Metal Roll Forming Machinery Available for Purchase

Custom Metal Roll Forming Machine for Sale An In-Depth Overview

The demand for precision-engineered metal components in various industries has led to the rise of advanced manufacturing technologies. Among these, the custom metal roll forming machine stands out as a vital tool in producing high-quality metal products. This article aims to provide an insightful overview of custom metal roll forming machines, their benefits, applications, and tips for purchasing.

Understanding Roll Forming Technology

Roll forming is a continuous bending operation in which metal strips or sheets are fed through a series of rollers, gradually shaping them into desired profiles. This process is highly efficient and cost-effective, making it ideal for high-volume production runs. Roll forming machines can produce a variety of profiles, including C-sections, Z-sections, and custom shapes tailored to specific requirements.

Advantages of Custom Metal Roll Forming Machines

1. Precision and Consistency One of the primary advantages of using a custom metal roll forming machine is the ability to maintain tight tolerances and produce consistent parts. This precision is crucial in industries such as construction, automotive, and aerospace, where the integrity of metal components significantly impacts final product performance.

2. Cost Efficiency While the initial investment in a custom machine may be higher than traditional methods, the long-term cost savings are substantial. Roll forming machines allow for higher production speeds and lower material waste, reducing overall manufacturing costs.

3. Versatility Custom metal roll forming machines can accommodate a wide range of materials, including steel, aluminum, and other alloys. Additionally, these machines can produce various shapes and sizes, making them suitable for diverse applications across different industries.

4. Enhanced Durability The roll forming process often enhances the strength characteristics of the final product, resulting in components that can withstand higher loads and stresses compared to those produced by other methods.

Applications of Custom Metal Roll Forming Machines

Custom metal roll forming machines find applications in various sectors, including

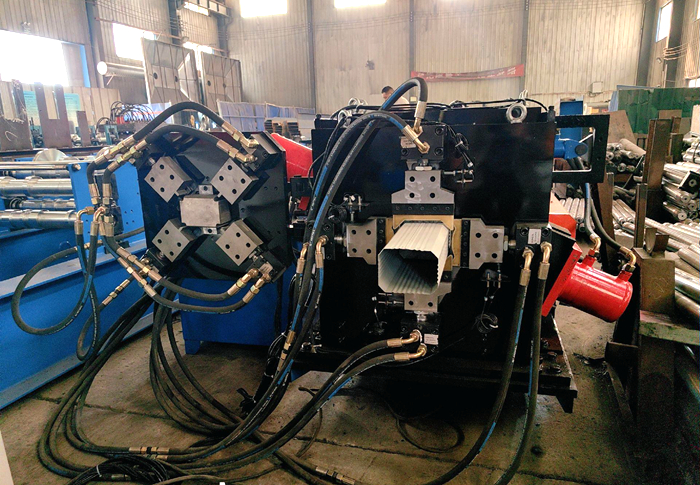

custom metal roll forming machine for sale

- Construction They are extensively used to manufacture structural components, such as steel framing, roofing systems, and wall panels. - Automotive Roll forming is employed to create chassis components, brackets, and reinforcements, delivering strength while minimizing weight. - Aerospace Aircraft manufacturers utilize roll-formed components for structural and aerodynamic applications, benefiting from the high strength-to-weight ratio. - HVAC Roll forming produces ducts, and other components tailored for heating, ventilation, and air conditioning systems, ensuring efficient airflow and energy savings.

Choosing the Right Custom Metal Roll Forming Machine

When looking to purchase a custom metal roll forming machine, several factors should be considered

1. Production Volume Assess your manufacturing needs. Will you be producing large quantities or specialty items? This will influence the machine's design and capabilities.

2. Material Requirements Ensure the machine can handle the materials you intend to use, including any specific thicknesses or alloys.

3. Customization Options Look for a manufacturer that can provide bespoke solutions tailored to your unique specifications, ensuring that the machine meets your production goals.

4. Support and Service Choose a supplier that offers robust customer support and maintenance services. This is crucial for minimizing downtime and ensuring long-term operational efficiency.

5. Budget Considerations While cheaper machines may be tempting, it’s essential to consider the total cost of ownership, including maintenance, parts, and operational efficiency.

Conclusion

Investing in a custom metal roll forming machine can enhance production capabilities, improve product quality, and ultimately reduce costs. Understanding the technology, its applications, and your specific needs will help in making an informed decision. As industries continue to evolve, the role of precision engineering in manufacturing will only grow, making roll forming an invaluable asset for any production facility.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025