c purlin roll forming machine supplier

The Importance of C Purlin Roll Forming Machines for Modern Construction

In the ever-evolving realm of construction and building materials, C purlins have emerged as a critical component for various structural applications. These channel-shaped steel components play a vital role in providing support for roofs, walls, and other architectural elements. With the increasing demand for efficient and high-quality construction, the significance of C purlin roll forming machines cannot be overstated. This article delves into the importance of these machines and the factors to consider when selecting a reliable supplier.

What are C Purlins?

C purlins are structural elements that are typically used in the construction of commercial buildings, warehouses, and industrial facilities. They offer exceptional strength to weight ratio, making them an ideal choice for supporting heavy loads without compromising structural integrity. C purlins are available in various sizes and thicknesses, enabling builders to select the most appropriate specifications for their projects.

The Role of Roll Forming Machines

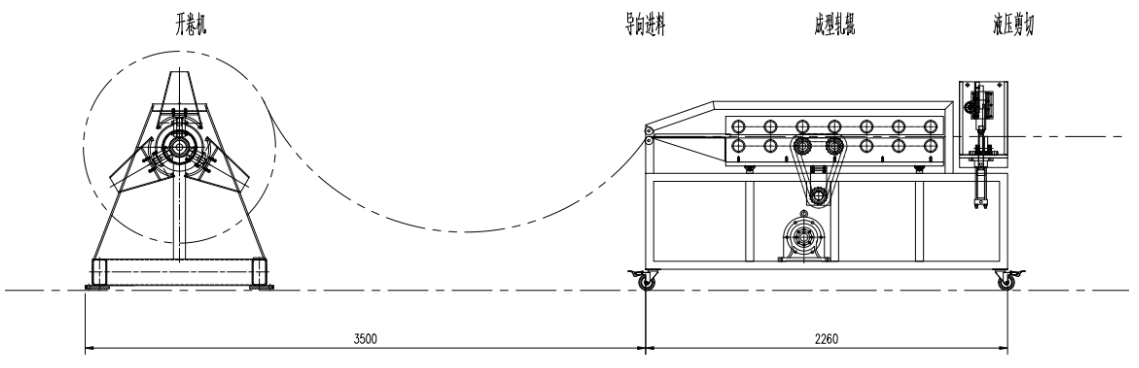

Roll forming machines are specialized equipment designed to manufacture C purlins from rolled steel. These machines operate by continuously feeding flat steel strip into a series of rollers, which gradually bend and shape the material into the desired profile. The efficiency of this process results in timely production, reduced material waste, and uniform product quality.

An effective C purlin roll forming machine can produce a wide range of purlin dimensions, fulfilling the diverse needs of construction projects. Furthermore, advanced machines are often equipped with computerized control systems that enhance accuracy and allow for easy adjustments during production.

Choosing a Reliable Supplier

When it comes to sourcing a C purlin roll forming machine, selecting a reputable supplier is crucial. Here are some factors to consider

1. Quality of Machines Ensure the supplier offers machines that meet international quality and safety standards. High-quality machines not only enhance production efficiency but also minimize maintenance costs in the long run.

c purlin roll forming machine supplier

2. Customization Options Different construction projects require specific profiles. Therefore, choose a supplier who can provide customization options to accommodate unique design requirements.

3. Technical Support and Service A reliable supplier should offer comprehensive technical support, including installation, training, and ongoing maintenance services. This support can significantly reduce downtime and improve overall production efficiency.

4. Reputation and Experience Look for suppliers with a solid reputation in the industry and extensive experience in manufacturing roll forming machines. Customer testimonials and case studies can provide insight into the quality of their products and services.

5. After-Sales Services Ensure that the supplier offers after-sales services, such as spare parts availability and prompt responses to service requests. This can save time and resources in case of any issues with the machinery.

Advantages of Using C Purlin Roll Forming Machines

Investing in a high-quality C purlin roll forming machine provides numerous advantages for construction businesses. Firstly, the automation of the production process significantly enhances efficiency, allowing manufacturers to produce large volumes of purlins in a shorter time frame.

Secondly, these machines contribute to cost savings by minimizing material wastage. The precision of roll forming ensures that each purlin is produced to the exact specifications required for the project, thereby reducing the likelihood of errors and rework.

Additionally, the ability to create customized profiles provides builders with more flexibility in design, enabling them to meet the specific needs of their clients.

Conclusion

In conclusion, C purlin roll forming machines are indispensable tools in the modern construction industry. They streamline the production process, ensure high-quality outputs, and offer the customization needed to cater to various project requirements. When choosing a supplier, it is vital to consider factors such as machine quality, customization options, technical support, and after-sales services. By making informed decisions, construction businesses can leverage these machines to enhance their productivity and competitiveness in the market. As the demand for robust and efficient construction materials continues to grow, investing in C purlin roll forming machines is a strategic move for any forward-thinking construction firm.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025