coil slitting line

Understanding the Coil Slitting Line in Metal Processing

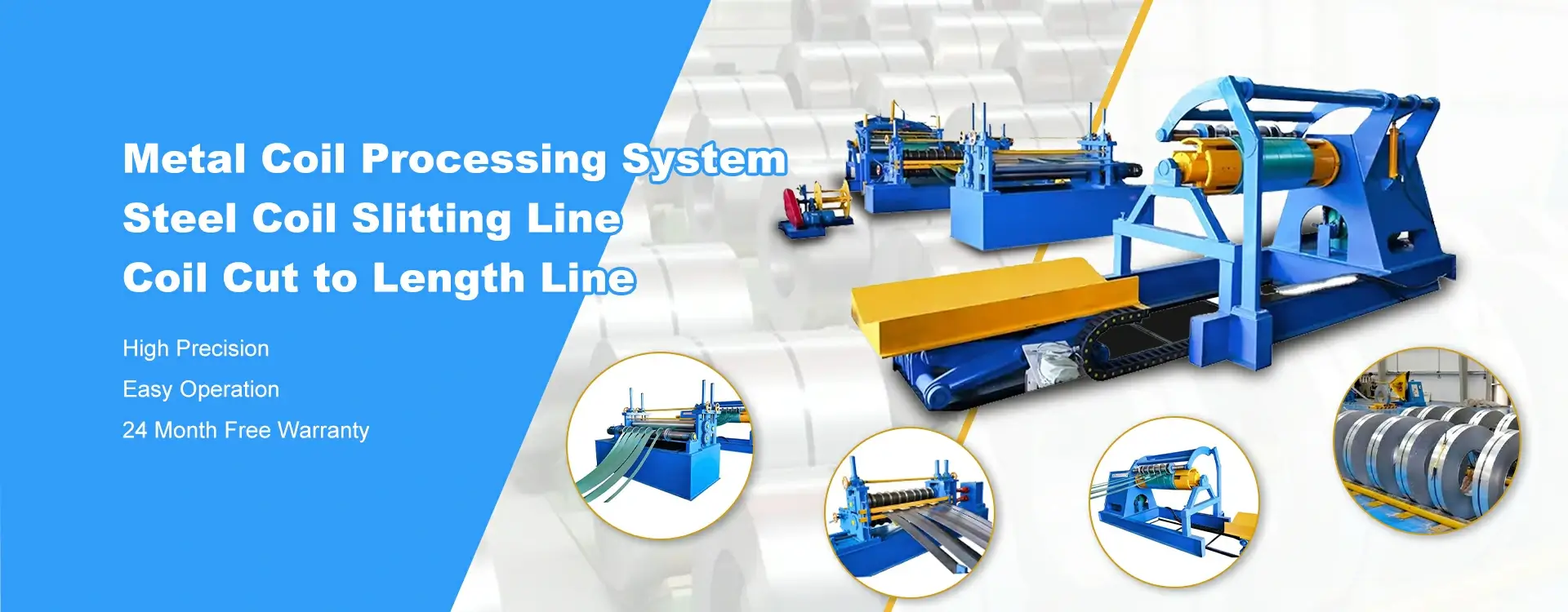

The coil slitting line is a crucial piece of equipment in the metal processing industry, particularly for those involved in the manufacturing and distribution of steel and aluminum products. The primary function of a coil slitting line is to cut large rolls, or coils, of metal into narrower strips that meet specific width requirements for various applications. This process not only enhances the material's usability but also increases efficiency in subsequent fabrication processes.

Components of a Coil Slitting Line

A standard coil slitting line comprises several key components a coil reel, tensioning units, slitting knives, a scrap removal system, and a recoiler. The coil reel holds the large parent coil, while the tensioning units ensure the metal is properly fed and tensioned during the slitting process. The slitting knives are critical, as they slice through the sheet metal, creating the desired strip widths. A scrap removal system is essential for handling the leftover material, ensuring a clean operation and minimizing waste. Finally, the recoiler collects the finished strips, winding them into manageable rolls.

The Slitting Process

The slitting process begins with the unwinding of the parent coil from the coil reel. As the metal is fed into the slitting area, the slitting knives are engaged, and the material is cut into strips. The precision of this cutting process is vital, as even minor inaccuracies can lead to significant waste during later stages of production. The use of high-quality, sharp knives and proper machine settings helps maintain tight tolerances.

Once the strips are cut, the scrap material—usually in the form of narrow steel bands—is collected by the scrap removal system. This is often done using a combination of magnetic and mechanical systems that ensure all leftover material is efficiently managed and recycled where possible.

coil slitting line

Advantages of Coil Slitting Lines

Investing in a coil slitting line provides several advantages for manufacturers. First and foremost, it allows for the efficient processing of materials to meet specific customer requirements. By producing narrow strips, companies can cater to niche markets, enhancing their product offerings.

Moreover, coil slitting lines are designed for high-speed operations, meaning they can process large volumes of material quickly, reducing labor costs and increasing productivity. This efficiency becomes even more significant in a competitive market, where speed to market can be a decisive factor.

Additionally, modern slitting lines are often equipped with advanced control systems and automation, allowing for precise adjustments and monitoring of the slitting process. This technological advancement minimizes the risk of material waste and ensures consistent quality across all products.

Conclusion

In conclusion, the coil slitting line plays an essential role in the metal processing industry by transforming large coils of metal into desirable strip widths for various applications. Understanding its components, processes, and advantages can provide manufacturers with a competitive edge in the marketplace. As industries continue to evolve and demand for tailored metal products grows, the coil slitting line will remain an indispensable asset, contributing to efficiency and innovation within the sector. Investing in such technology not only streamlines operations but also opens the door to new possibilities in product offerings and market reach.

-

Optimizing Your Production with CZ Purlin MachinesNewsMay.19, 2025

-

Maximizing Efficiency with C and U Channel Roll Forming MachinesNewsMay.19, 2025

-

Investing in Z Purlin MachinesNewsMay.19, 2025

-

Efficient Solutions with Metal Stud and Track Roll Forming MachinesNewsMay.19, 2025

-

Choosing the Best C Purlin MachinesNewsMay.19, 2025

-

Boost Your Production with Wall Angle Roll Forming MachinesNewsMay.19, 2025

-

Understanding Steel Coil Cutting Machines and Their ImportanceNewsMay.16, 2025