Efficient Channel Framing Roll Forming Machine for Precision Construction Applications

Understanding Channel Framing Roll Forming Machines

In the realm of manufacturing and metalworking, efficiency and precision are paramount. One of the vital processes contributing to these goals is roll forming, particularly through the use of channel framing roll forming machines. These machines play a crucial role in shaping and fabricating metal channels, which serve essential functions in construction, automotive, and various industrial applications.

What is Roll Forming?

Roll forming is a continuous bending operation that converts a long strip of metal, typically coiled steel, into a desired cross-sectional profile. This process involves passing the metal through a series of rollers, each designed to incrementally shape the metal until it reaches the final profile. The primary advantage of roll forming is its ability to produce long lengths of parts with high precision and repeatability.

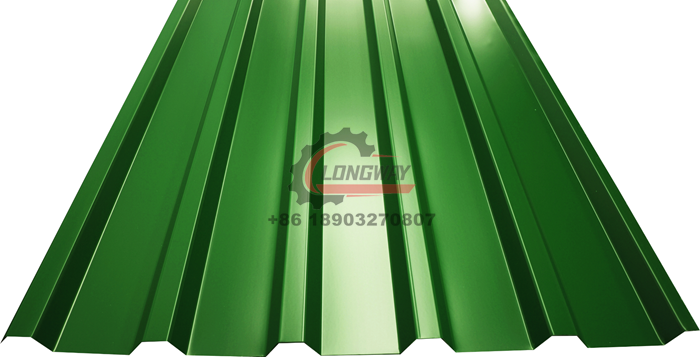

Channel framing roll forming machines are specifically designed to create C or U-shaped channels that are widely used in framing applications. This type of roll forming machine ensures that the channels maintain uniform thickness, strength, and quality throughout the entire length of the section produced.

Key Components of Channel Framing Roll Forming Machines

A typical channel framing roll forming machine comprises several components that work in harmony to achieve the desired product. Here are the main parts

1. Uncoiler This component unwinds coils of sheet metal for processing. It ensures a steady supply of metal into the roll forming system.

2. Rollers The heart of the machine, rollers are specially designed to shape the metal. Different sets of rollers are configured to achieve varying geometries, allowing for customization of channel sizes and profiles.

3. Forming Table The metal passes through a forming table where initial bending occurs. This stage sets the base shape before final shaping occurs in subsequent roller stations.

channel framing roll forming machine

5. Stacker The finished channel sections are then automatically or manually collected and stacked for easy handling and delivery.

Applications of Channel Framing

Channel sections produced by these machines find their way into numerous applications. In construction, they are widely used as structural support in buildings, both residential and commercial. Their strength and lightweight properties make them ideal for framing walls, roofs, and floors. In the automotive industry, channel framing components are used for car frames and other structural elements, contributing to the overall durability and safety of vehicles. Additionally, they are essential in manufacturing applications for creating frames for machinery, shelving units, and other industrial structures.

Benefits of Using Channel Framing Roll Forming Machines

The advantages of employing channel framing roll forming machines are numerous

- Efficiency Roll forming is a continuous process that can produce large quantities of channels with minimal waste. The setup, once established, allows for high-speed production.

- Cost-Effectiveness The reduction in material wastage, coupled with the machine's ability to produce consistent quality parts, results in lower manufacturing costs.

- Customizability Manufacturers can easily modify the tooling to create different channel profiles, catering to various market needs without significant downtime.

- Durability and Quality The controlled manufacturing process ensures that the final products possess high strength and durability, which is critical in structural applications.

Conclusion

In summary, channel framing roll forming machines are indispensable in modern manufacturing. They provide an efficient means of producing high-quality metal channels that serve various industries from construction to automotive. With their ability to enhance productivity, reduce costs, and maintain quality, these machines exemplify the advancements in metal forming technology that continue to shape the manufacturing landscape. As demand for lightweight yet strong materials grows, the importance of channel framing roll forming machines will only increase, paving the way for innovative solutions in building and manufacturing processes.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025