Affordable Options for Roll Forming Machines You Should Consider

Affordable Types of Roll Forming Machines

Roll forming is a widely used manufacturing process that converts flat metal sheets into specific shapes by passing them through a series of rollers. This technique is highly sought after in industries such as construction, automotive, and appliance manufacturing due to its efficiency and ability to produce consistent profiles. However, investing in a high-quality roll forming machine can be a significant financial commitment. Fortunately, there are several affordable types of roll forming machines available that cater to various production needs without breaking the bank.

1. Basic Manual Roll Forming Machines

For small businesses or startups, manual roll forming machines are an excellent entry point into the world of roll forming. These machines are simple to operate and require minimal upfront investment. Typically designed for low-volume production, manual roll forming machines allow operators to feed metal sheets manually into the rollers. While these machines may lack the automation and speed of more advanced models, they provide a cost-effective solution for producing basic shapes and profiles on a small scale.

2. Entry-Level Electric Roll Forming Machines

For businesses looking to scale production while maintaining affordability, entry-level electric roll forming machines are a popular choice. These machines use electric drives, providing increased speed and efficiency compared to manual machines. They are suitable for producing a variety of profiles, including roof panels, wall panels, and guttering. Although they come with a higher price tag than manual machines, entry-level electric models offer better productivity and precision, making them a wise investment for companies focused on growing their output.

3. Semi-Automatic Roll Forming Machines

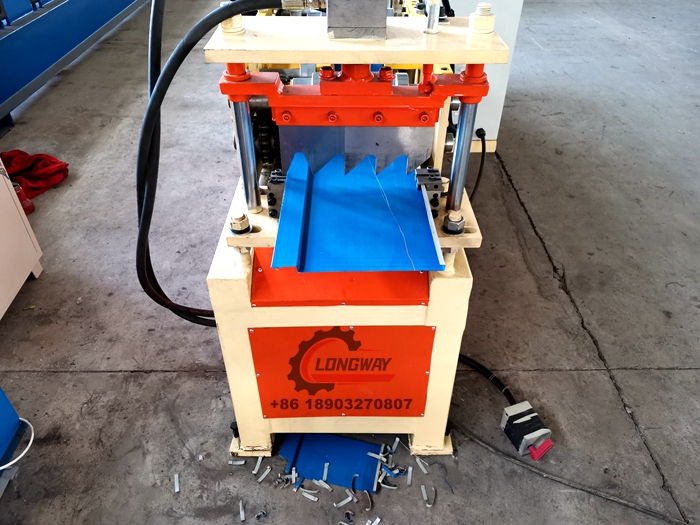

cheap types of roll forming machine

Semi-automatic roll forming machines are designed for businesses that require a balance between affordability and efficiency. These machines can work with various metal materials and are capable of producing complex profiles. Semi-automatic models often feature automation elements, such as automatic feeding and cutting systems, which streamline the production process while still being budget-friendly. They are ideal for medium-sized businesses seeking to improve productivity without incurring the high costs associated with fully automatic machines.

4. Compact Roll Forming Machines

Compact roll forming machines are designed for small spaces while maintaining functionality and affordability. These machines are often lighter and smaller than their larger counterparts, making them suitable for workshops with limited floor space. Despite their compact size, they can still deliver high-quality profiles and are particularly popular among manufacturers specializing in custom projects. Businesses looking for versatility without large financial outlays will find compact roll forming machines to be a practical option.

5. Used or Refurbished Roll Forming Machines

Another cost-effective option is purchasing used or refurbished roll forming machines. Many manufacturers upgrade their equipment or go out of business, leaving behind machines that are still in good working condition. Buying second-hand can significantly reduce initial investment costs. However, it’s essential to conduct thorough research and inspection before making a purchase to ensure that the machine meets production requirements and is reliable.

Conclusion

Investing in a roll forming machine doesn't have to be prohibitively expensive. With a variety of affordable options available, including manual machines, entry-level electric models, semi-automatic machines, compact designs, and even used equipment, businesses of all sizes can find a solution that fits their needs and budget. When selecting a roll forming machine, it’s vital to assess production requirements, available space, and budget constraints, ensuring that the chosen equipment will provide the best value and efficiency for years to come.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025