Jan . 16, 2025 05:46

Back to list

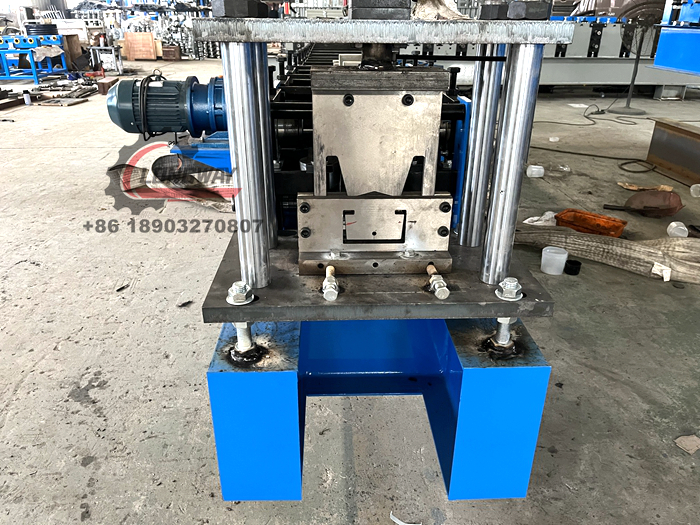

Metal sheet Perforados punching machine

When exploring the world of advanced manufacturing, the rolling shutter machine stands out as an essential tool for industries seeking precision and efficiency. Its evolution and application transcend simple mechanics to embody technological artistry, aimed at optimising production processes and product quality. Renowned for their role in producing superior rolling shutters for commercial and residential buildings, these machines not only enhance functional efficiency but also significantly contribute to aesthetic appeal.

When it comes to authoritativeness, brands known for pioneering innovations in rolling shutter machines remain at the forefront. Companies that invest in R&D to continually refine mechanism efficiency and product output validate their authoritative position in the market. They often lead training workshops and offer certification programs to boost skill levels within the industry, contributing invaluable knowledge to upcoming engineers. Trustworthiness in rolling shutter machine operation is non-negotiable, given the significant investment each machine entails for manufacturers. Dependable machines have undergone rigorous testing and quality assurance processes. Insights from long-term users highlight the durability and cost-effectiveness of these machines, providing testimonials of their dependability. Transparently published service records and warranties further solidify this trust. In conclusion, owning or operating a rolling shutter machine is an investment in technology and skill that extends beyond traditional boundaries, pushing for a balance between functionality and form. A deep understanding and responsible application of their capabilities can lead to groundbreaking developments in architectural design and functionality, promoting efficiency and sustainability in manufacturing processes. This commitment to the seamless integration of technology and user expertise propels companies to new heights in the ever-evolving landscape of industrial machinery.

When it comes to authoritativeness, brands known for pioneering innovations in rolling shutter machines remain at the forefront. Companies that invest in R&D to continually refine mechanism efficiency and product output validate their authoritative position in the market. They often lead training workshops and offer certification programs to boost skill levels within the industry, contributing invaluable knowledge to upcoming engineers. Trustworthiness in rolling shutter machine operation is non-negotiable, given the significant investment each machine entails for manufacturers. Dependable machines have undergone rigorous testing and quality assurance processes. Insights from long-term users highlight the durability and cost-effectiveness of these machines, providing testimonials of their dependability. Transparently published service records and warranties further solidify this trust. In conclusion, owning or operating a rolling shutter machine is an investment in technology and skill that extends beyond traditional boundaries, pushing for a balance between functionality and form. A deep understanding and responsible application of their capabilities can lead to groundbreaking developments in architectural design and functionality, promoting efficiency and sustainability in manufacturing processes. This commitment to the seamless integration of technology and user expertise propels companies to new heights in the ever-evolving landscape of industrial machinery.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products