roll forming machine-What is roll forming?

Roll Forming

This is the most complete description of roll forming on the internet.

You will learn:

- What is roll forming

- Roll forming processes

- Technical advances in roll forming

- The benefits and advantages

- Metals that can be roll formed

- And much more

-

Chapter One – What is roll forming?

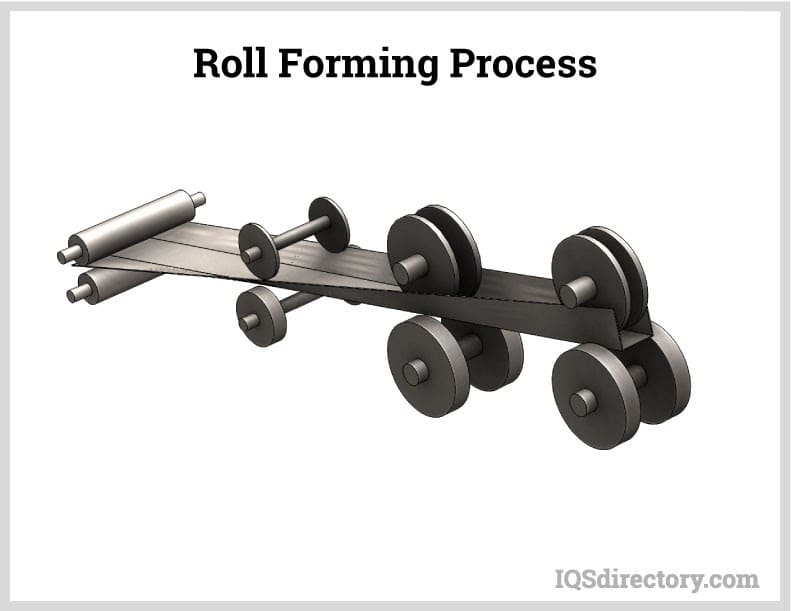

Roll forming is a process that uses a set of precisely placed rollers to perform incremental bending to a continuously fed strip of metal. The rollers are mounted in sets on a consecutive stand with each roller completing one small step of the process.

Rollers are carefully crafted using a flower pattern, which identifies the sequential changes to the metal strip. The shape of each roller is created from the individual sections of the flower pattern.

-

Each of the colors in the above flower pattern illustrates one of the incremental bends used to complete the part. The individual colors are a single bending operation. CAD or CAM renderings are used to simulate the roll forming process so that errors or flaws can be prevented prior to production. Using software applications, engineers can select calibrations and profiles for folding or bending angles to create new geometries by clicking their mouse.

Chapter Two – Roll Forming Process

Each roll forming manufacturer has a different set of steps for their roll forming process. Regardless of the variations, there are a set of basic steps all producers use.

The process begins with a large coil of sheet metal that can be from 1 inch to 30 inches wide with a thickness of 0.012 inch to 0.2 inch. Before a coil can be loaded, it has to be prepared for the process.

-

The above diagram represents each step of roll forming from the feeding of the coil to the cutoff and discharge at the end of the process. Below is a description of each step.

Steps of the Roll Forming Process

Uncoiling

Metal coils may become set during storage and have a tendency to stay coiled and become distorted. To correct the problem, the coil is loaded onto the uncoiler, seen below, and fed through a flattener to remove the coil set. The lead end is trimmed to allow for smooth feeding into the pre-press process.

Part of the pre-press operation may be a tapering of the beginning of the feed coil to make it easier for it to slide into the forming rollers.

-

Pre-press treatment

Before the metal from the coil is fed into the roll forming rollers, it may need applications added as can be seen in the image below, which can involve adding slots, holes, or slits.

-

Roll forming

At this stage, the material is progressively shaped. A typical roll forming machine can consist of 10 to 24 pairs of roller die stands. The machine is individually or gang driven to force the ribbon of metal through the rollers that gradually shape it to the dimensions of the flower pattern.

Cutoff and discharge

Parts are cut to length as they are in motion, which increases the efficiency and speed of the roll forming process. Once they are cut, they are discharged to a run-out table to be placed for shipment or further processing.

-

Metal sheet Perforados punching machine

Secondary processes

There are a variety of ways secondary processes can be performed. Some can be completed as the part comes off the cutoff, while others may have to be performed at another station.

The image below has samples of some of the listed secondary processes, which include:

- Punching

- Notching

- Tight tolerance forming

- Straightening

- Adding other components

- Minor assembly

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025