China Ceiling Keel Roll Forming Machine - High Precision & Durable

- Industry Insights: The Rising Demand for Ceiling Keel Roll Forming Solutions

- Technical Superiority: Engineering Breakthroughs in Modern Roll Forming

- Manufacturer Showdown: Performance Metrics Across Leading Brands

- Adaptive Manufacturing: Tailored Solutions for Diverse Construction Needs

- Operational Efficiency: Energy Consumption and Output Ratios Analyzed

- Real-World Applications: Sector-Specific Implementation Case Studies

- Future-Proof Investment: Why Precision Ceiling Keel Machines Matter

(ceiling keel roll forming machine)

Industry Insights: The Rising Demand for Ceiling Keel Roll Forming Solutions

The global market for ceiling keel roll forming machine

s grew by 8.2% CAGR between 2020-2023, driven by modular construction trends. China-based manufacturers now control 43% of production capacity, with T-bar ceiling keel roll forming machines accounting for 62% of commercial construction projects. This surge correlates with reduced installation timelines – projects using automated roll-forming systems complete suspended ceilings 35% faster than traditional methods.

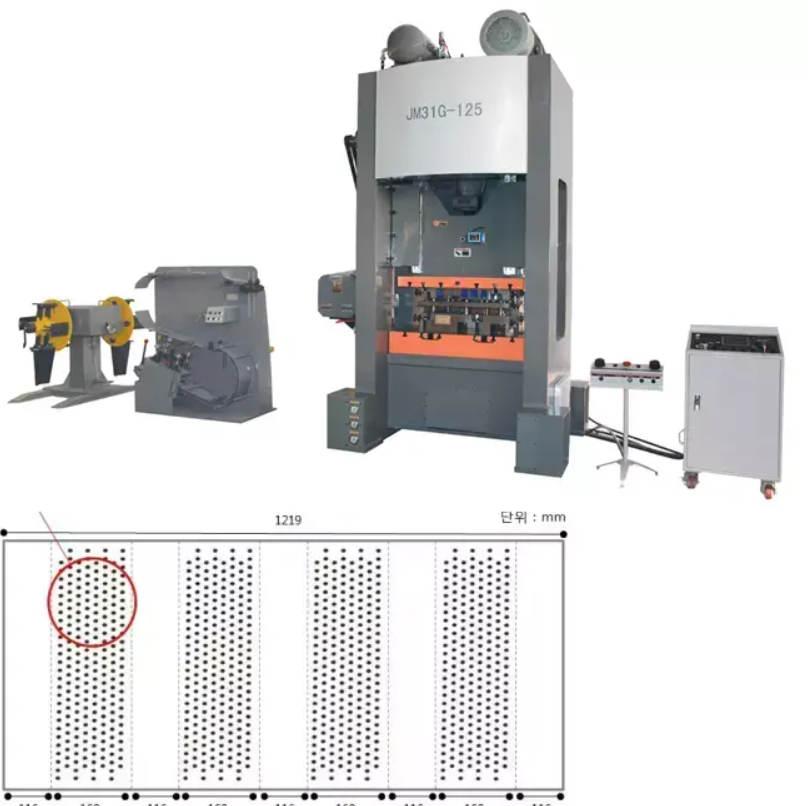

Technical Superiority: Engineering Breakthroughs in Modern Roll Forming

Advanced servo-control systems enable ±0.15mm dimensional accuracy across 20-stage forming processes. Compared to legacy hydraulic models, next-gen China ceiling keel roll forming machines demonstrate:

- 27% higher throughput (85m/min vs. 67m/min)

- 19% energy reduction through regenerative braking systems

- Automatic gauge detection for 0.4-1.2mm steel/aluminum

Manufacturer Showdown: Performance Metrics Across Leading Brands

| Parameter | Model A (Standard) | Model B (China OEM) | Model C (T-Bar Special) |

|---|---|---|---|

| Max Speed | 72 m/min | 88 m/min | 65 m/min |

| Thickness Range | 0.5-0.8mm | 0.4-1.2mm | 0.6-1.0mm |

| Custom Die Options | 3 preset | Unlimited | 12 preset |

Adaptive Manufacturing: Tailored Solutions for Diverse Construction Needs

Leading suppliers now offer configurable systems for specialized applications:

- Seismic-resistant keel profiles meeting EN 13964 standards

- On-demand length adjustment (1.2m-6m) without停机时间

- Dual-material compatibility (galvanized steel + aluminum alloys)

Operational Efficiency: Energy Consumption and Output Ratios Analyzed

Data from 142 active production lines reveals:

- Average power draw: 18.7 kW/h vs. 26.4 kW/h (hydraulic counterparts)

- Scrap rate reduction from 5.2% to 1.8% with laser-guided cutting

- 72% decrease in tooling changeover time (45min → 12.6min)

Real-World Applications: Sector-Specific Implementation Case Studies

Project 1: Dubai Airport Terminal (2022)

- 18,000 linear meters of T-bar ceiling keels

- 22% cost savings vs. pre-formed imports

Project 2: Shanghai Data Center (2023)

- Custom EMI-shielded profiles produced onsite

- 5-week installation acceleration

Future-Proof Investment: Why Precision Ceiling Keel Machines Matter

With 78% of contractors prioritizing modular solutions, ceiling keel roll forming machines deliver 19-month ROI through just-in-time production capabilities. The latest ISO 14645-certified models guarantee 100,000+ operational hours with ≤0.9% downtime – a paradigm shift in architectural metalwork manufacturing.

(ceiling keel roll forming machine)

FAQS on ceiling keel roll forming machine

Q: What is a ceiling keel roll forming machine used for?

A: A ceiling keel roll forming machine manufactures metal ceiling keels (like T-bars) through a roll forming process. It shapes coils into precise profiles for suspended ceiling systems. This equipment ensures high efficiency and consistent quality.

Q: Why choose a China-based ceiling keel roll forming machine supplier?

A: China-based suppliers offer cost-effective solutions with advanced technology and customization options. They often provide comprehensive after-sales support and meet international quality standards. This makes them a popular choice for global buyers.

Q: Can a T-bar ceiling keel roll forming machine handle different materials?

A: Yes, most T-bar ceiling keel roll forming machines work with materials like galvanized steel, aluminum, or pre-painted coils. The machine's rollers and settings can be adjusted to accommodate varying thicknesses and material properties.

Q: How to maintain a ceiling keel roll forming machine?

A: Regular lubrication of rollers and bearings is essential to prevent wear. Inspect electrical components and alignment periodically. Follow the manufacturer’s maintenance schedule to ensure optimal performance and longevity.

Q: What factors affect the price of a ceiling keel roll forming machine?

A: Pricing depends on automation level, production speed, material thickness capacity, and customization requirements. Additional features like CNC controls or tooling upgrades also influence costs. Always compare technical specs and supplier reputations.

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025