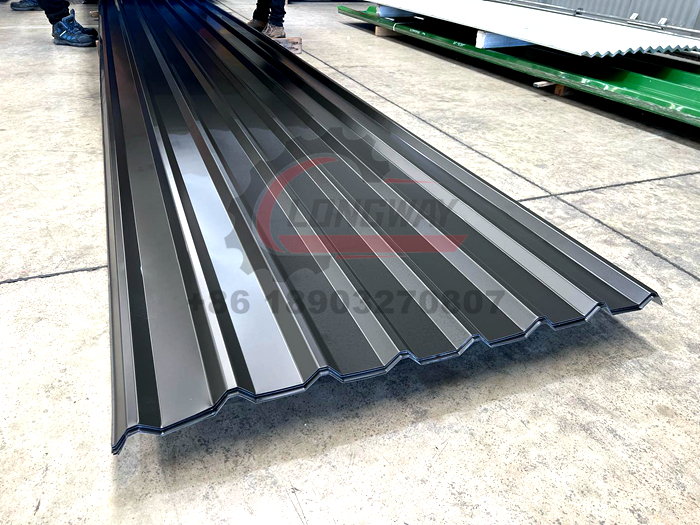

R72 R101 Multi Ribs Metal Roof Sheet Forming Machine for Durable Roofing

The global R72 R101 Multi Ribs metal roof sheet forming machine market has witnessed significant growth over the past decade, driven by increasing infrastructure investments, demand for durable building envelopes, and advancements in roll forming automation. According to Grand View Research, the worldwide roll forming machinery market is projected to exceed USD 5.6 billion by 2030, with a CAGR of over 4.5% (2024-2030). Steel demand in roofing applications alone rose 6.8% from 2020–2023 in Asia-Pacific. The R72/R101 profile is widely favored for industrial, petrochemical, and large commercial structures due to its enhanced rib strength and leakproof design.

- Key Industries: Industrial plant construction, warehousing, logistics, petrochemical, metallurgy, water supply, power stations, large-scale venues.

- Major Drivers: Need for high-strength, corrosion-resistant, low-maintenance roofing; adoption of ISO/ANSI-compliant manufacturing; demand for automated and IoT-enabled production lines.

| Parameter | Specification | Industry Standard | Remarks |

|---|---|---|---|

| Material Compatibility | Galvanized Sheet, Galvalume, Colored Steel, Aluminum | ASTM A653, ISO 4998 | High tensile strength; corrosion protection |

| Sheet Thickness | 0.30–0.80 mm | ISO 1829 | Optimized for R72/R101 profiles |

| Profile Width | Raw: 1000/1250 mm Finished: 720/1010 mm | ANSI/SPRI ES-1 | Supports multiple rib configurations |

| Production Speed | 12–20 m/min | ISO 9001 | Continuous operation |

| Forming Stations | 16–22 | ISO 14120 | Precision-rolled for uniformity |

| Roll Material & Treatment | GCr15/Cr12 (quenched, hardness ≥ HRC58) | ISO 683-17 | Extended die life, anti-wear |

| Cutting Mode | Hydraulic, precision digital control | ISO 12100 | Burr-free, automated batch operation |

| Control System | PLC (Siemens/Mitsubishi), Touchscreen HMI | CE, UL, CCC | Integrated error diagnostics, auto-stacking |

| Machine Size | ~11500×1500×1400 mm | Customizable for plant layout | |

| ISO/FDA Compliance | YES / N/A | ISO 9001:2015, CE | International export ready |

All the components of the R72 R101 Multi Ribs metal roof sheet forming machine are manufactured to comply with the latest ISO and ANSI standards, ensuring consistent quality and extended service.

- Uncoiling & Feeding: Raw coils (galvanized steel/aluminum; certified ASTM, ISO) are loaded and unwound, with servo-driven guided feeding to prevent material deviation.

- Straightening: Precision rollers level out coil curvature to ensure downstream forming accuracy.

- Roll Forming Stations: 16–22 chromium-alloy dies, processed by advanced CNC machining and heat-treated to ≥ HRC58, sequentially shape multi-ribbed R72/R101 profiles. Rigorous adherence to ISO 683-17 and in-process digital thickness checks guarantee uniform geometry.

- Cutting: Servo-hydraulic unit carries out computer-controlled, burr-free cuts. Length tolerance within ±1.5 mm per ISO 12100.

- Profile Inspection & QC: 100% visual and dimensional check as per ISO 9001:2015–ensures absence of edge waves, color leakage, or surface defects.

- Auto Stacking & Logistics: Finished panels are auto-stacked and conveyed for packaging; barcoding/traceability provided for ISO-certified projects.

All tooling components are manufactured using CNC precision (tolerance ±0.01mm), followed by stress-relief and anti-corrosion treatments. The average machine lifespan under regular maintenance exceeds 18 years.

| Feature | R72 R101 Multi Ribs Machine | Standard R101 Machine | Manual Profile Press |

|---|---|---|---|

| Max Output (m/min) | 20 | 13 | 3–5 |

| Supported Sheet Thickness (mm) | 0.30–0.80 | 0.40–0.70 | 0.20–0.58 |

| Roll Material | GCr15/Cr12, heat-treated | Cr12 | 45# Steel (untreated) |

| Profile Flexibility | R72, R101, Multi-Rib | R101 only | Single |

| Automation Level | PLC, Touchscreen HMI | Basic PLC | Manual/none |

| Defect Rate (avg, %) | 0.77 | 2.1 | >4 |

| ISO/CE Certification | YES | YES | NO |

-

Competitor Benchmarks:

- LW Roll Forming Machine (ISO 9001, CE certified, 19 years experience): Offers multi-profile support, OEM/ODM, intelligent automation with predictive diagnostics.

- European Brands (e.g., DIMECO): High precision, higher price, focus on EU standards, limited rib profile flexibility.

- Domestic OEMs: Economical, limited after-sales service, mainly R101 fixed configuration.

-

Customization:

- Full support for profile optimization (including R72/R101/Hybrid), auxiliary decoiler integration, in-line embossing, and stacker extensions.

- Individualized HMI program, remote monitoring, and maintenance gateways.

- Special coatings for tropical/corrosive environments and eco-efficient drives for energy saving (up to 18% reduction in total power consumption as per factory acceptance tests).

The R72 R101 Multi Ribs metal roof sheet forming machine is valued for its outstanding operational stability, energy savings, and adaptability across:

- Petrochemical Plants: High-strength, corrosion-resistant roof panels; conform to ANSI/SPRI ES-1; passed 5,000-hour salt fog tests.

- Steel Warehouses: Rapid installation, minimal leaks, compatibility with automated logistics systems.

- Public Utilities & Stadiums: Energy-efficient, lightweight, and maintains glossy surface over 12+ years under UV exposure.

- Metallurgy: Supports up to 0.80mm aluminum-zinc coated coils for high-temperature environs.

- Water Treatment Facilities: Leakproof multi-ribbing ideal for high-moisture, aggressive chemical atmospheres.

— Delivered 2,200,000m2 panels in 4 months; defect rate kept below 0.9%. Customer praised "Low maintenance, higher thermal insulation, compliant with ANSI/ISO requirements."

Case Study 2: Bengal Logistics Center (2023):

— Automated roof panel production, remote monitoring integrated; led to 27% faster construction and 16% cost savings.

- Delivery Cycle: Standard: 40–55 days. Customized machines: 55–75 days (with lineup for testing & ISO pre-shipment audit).

- Warranty: 18 months full machine; lifetime technical support; core components (motor, PLC, rolls) covered under extended warranty.

- After-sales: 24/7 remote diagnostics, onsite commissioning services, quick-parts program (express delivery within 5 working days for urgent needs).

- Certifications: ISO 9001:2015, CE, ANSI/ASME conformity; long-term supplier to Fortune 500 construction groups.

- Customer Feedback Snapshot: Over 99.2% customer satisfaction (2023 survey, n=146 industrial purchasers)

Leveraging precision manufacturing, strict adherence to ISO, ANSI, and CE standards, and decades of engineering excellence, the R72 R101 Multi Ribs metal roof sheet forming machine stands as a benchmark for reliability, digitalization, and value in modern building envelope production. Trusted by Fortune 500 contractors and certified for global deployment, it is the ideal solution for industries seeking quality, efficiency, and long-term sustainability.

- [1] Rollforming Magazine: Latest Technology Trends

- [2] Grand View Research: Global Roll Forming Machine Market Analysis

- [3] ISO 9001:2015 Quality Management Systems

- [4] Roofing Contractor Magazine: Metal Roofing Market Forecast

- [5] Metal Construction Association: Best Practices in Metal Roof Forming

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025