Purlin Machines: Types, Features, and Pricing Guide

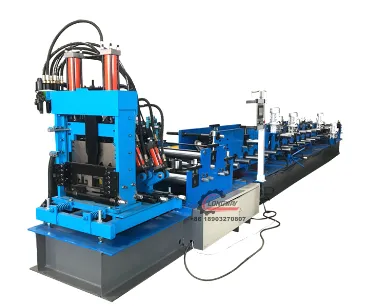

A purlin machine is a roll forming machine designed to produce steel structural elements known as purlins, which are commonly used in roofing and wall support frameworks for metal buildings. Whether you're in steel fabrication, construction, or pre-engineered building (PEB) manufacturing, owning a purlin roll forming machine allows you to produce components on-demand with precision and efficiency.

If you're looking for a purlin machine for sale, comparing specifications, production capabilities, and understanding the purlin machine price will help you choose the right equipment for your operation.

What Is a Purlin Machine

A purlin machine forms galvanized steel, cold-rolled steel, or other metals into C-shaped, Z-shaped, or interchangeable C/Z purlin profiles. These machines are designed to roll form flat steel strips into purlins of varying widths, heights, and thicknesses. Most machines today are fully automated and controlled by PLC systems for precise dimension control.

Purlins produced by these machines are widely used in:

Industrial steel buildings

Warehouses and sheds

Carports and garages

Steel frame residential housing

Agricultural structures

Types of Purlin Machines

1. C Purlin Machine

Produces C-shaped purlins in various sizes. These purlins are typically used for wall and floor joists, roof support beams, and structural framing.

2. Z Purlin Machine

Forms Z-shaped purlins used in roofing systems, particularly where lapping is needed to increase span and strength.

3. Interchangeable C/Z Purlin Machine

Offers the flexibility to produce both C and Z profiles on a single machine. Changeover between profiles can be manual or automatic, depending on machine type.

4. Hat Purlin Machine

Less common but used for specific light-duty applications like partition walls or ceilings.

Key Features of a Purlin Machine

Roll Forming Stations

Depending on the thickness and profile complexity, machines may have 13 to 20+ forming stations.

Profile Size Range

Typical machines can produce purlins from 80 mm to 300 mm in width, with thicknesses from 1.2 mm to 3.0 mm or more.

Adjustable Width and Height

Hydraulic or motorized adjustments for width and flange height allow flexible production without changing rollers.

Cutting System

Hydraulic cutting with flying shear or stop-to-cut systems, often integrated with PLC control for precise lengths.

Punching System

Optional inline hydraulic punching for holes, slots, or notches used in bolting or structural connections.

PLC Control Panel

Automated length setting, batch quantity control, and error alerts via a user-friendly touch screen interface.

Material Compatibility

Machines typically handle galvanized steel, cold-rolled steel, or mild steel coils.

Purlin Machine Price Overview

The purlin machine price varies depending on configuration, automation level, production capacity, and supplier origin.

Estimated Price Ranges (USD)

|

Machine Type |

Typical Price Range |

|

C Purlin Machine (manual adjust) |

$15,000 – $25,000 |

|

Z Purlin Machine |

$18,000 – $30,000 |

|

C/Z Interchangeable (manual) |

$25,000 – $40,000 |

|

C/Z Interchangeable (auto-adjust) |

$40,000 – $65,000+ |

Additional equipment costs:

Decoiler (manual or hydraulic): $2,000 – $6,000

Hydraulic punching unit: $3,000 – $8,000

Stacking table or output rack: $1,000 – $3,000

The total investment depends on whether you need a basic setup or a high-output automated line.

What to Consider Before Buying a Purlin Machine

Profile Requirements

Define which purlin profiles (C, Z, or both) and sizes you need. This will guide machine type and tooling configuration.

Production Volume

If you need frequent size changes or high output, an automatic adjustable machine is worth the higher investment.

Material Specs

Confirm that the machine handles your target material type, width, and thickness range.

Automation Level

Consider how much manual adjustment your operation can handle. Auto-adjust and auto-punch systems reduce labor and increase speed.

Supplier Reputation

Choose a manufacturer with proven experience, detailed technical specs, post-sale support, and available spare parts.

Installation and Training

Check if the supplier offers on-site setup and operator training, especially for automated models.

Applications of Purlin Machines

Manufacturing of steel building structures

Production of roofing and wall support systems

Pre-engineered building kits

Steel warehouse and garage framing

Agricultural building construction

Carport and shed production lines

Whether you're producing for your own projects or selling structural components to contractors, owning a purlin machine can reduce costs and improve supply flexibility.

A purlin machine is a valuable asset for metal building manufacturers, steel fabricators, and construction material suppliers. With the ability to produce C, Z, or combined purlin profiles in-house, businesses can reduce lead times, improve product consistency, and expand their offerings.

When searching for a purlin machine for sale, assess your technical requirements, production goals, and the full range of features before making a purchase. Understanding the real purlin machine price and comparing manual versus automatic options will help you choose the right solution for long-term profitability.

Purlin Machine FAQs

What is the difference between C and Z purlins?

C purlins are symmetrical and easier to install but have limited span. Z purlins have a diagonal shape that allows lapping and longer spans.

Can one machine make multiple purlin sizes?

Yes. Most modern purlin machines allow width and height adjustments to produce various sizes. Some support automatic adjustment without roller change.

Is punching included in the machine?

Some machines come with inline hydraulic punching units for bolt holes and slots. Others may require a separate punching machine.

How long does it take to switch between sizes?

In manual machines, changeover can take 15–30 minutes. In auto-adjust machines, changeover can be done in under 5 minutes via touchscreen settings.

Do purlin machines require special foundations?

Standard industrial concrete flooring is usually sufficient. Heavy-duty machines may require reinforced foundations, depending on size and weight.

-

Corrugated iron roofing sheet making machine with CE, AutoΝέαNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyΝέαNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCΝέαNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseΝέαNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseΝέαNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableΝέαNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CEΝέαNov.11, 2025