Metal Stud Roll Formers High-Efficiency Custom Manufacturing Solutions

- Industry overview & technological advancements

- Engineering innovations in production systems

- Performance comparison of leading manufacturers

- Custom configuration capabilities

- Cross-industry implementation scenarios

- Operational cost analysis

- Sector development projections

(metal stud roll former)

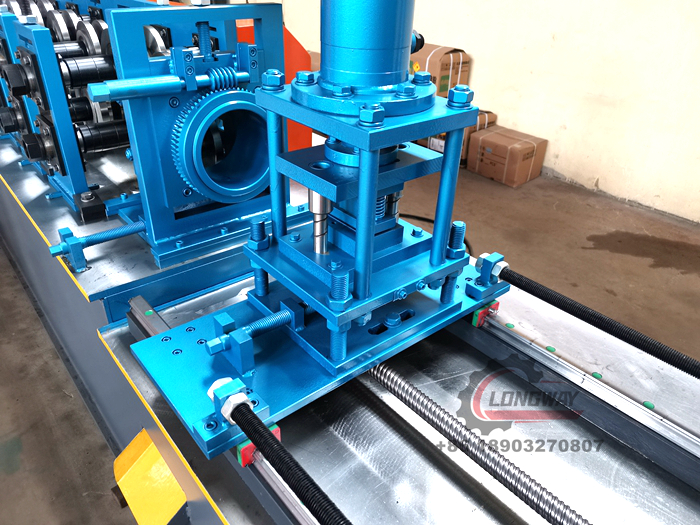

The Evolution of Metal Stud Roll Former Technology

Modern construction methodologies demand precision-engineered solutions, with metal stud roll former

s becoming indispensable across commercial projects. Industry reports indicate a 6.8% CAGR growth (2023-2030) for cold-formed steel framing systems, driven by their 40% weight reduction compared to traditional wood framing. Leading metal stud roll former manufacturers now integrate IoT-enabled monitoring, achieving 0.02mm dimensional accuracy through closed-loop servo control systems.

Engineering Breakthroughs in Forming Systems

Third-generation machines feature:

- Dual-axis automatic lubrication (38% maintenance reduction)

- Adaptive roll gap compensation (±0.015mm consistency)

- Energy recovery systems (22% power consumption decrease)

These advancements enable continuous 55m/min operation while maintaining 98.7% material utilization rates.

Manufacturer Capability Benchmarking

| Parameter | Company A | Company B | Company C |

|---|---|---|---|

| Max Line Speed | 45m/min | 52m/min | 48m/min |

| Material Thickness | 0.4-2.0mm | 0.6-2.5mm | 0.5-2.2mm |

| Tooling Change Time | 18min | 12min | 15min |

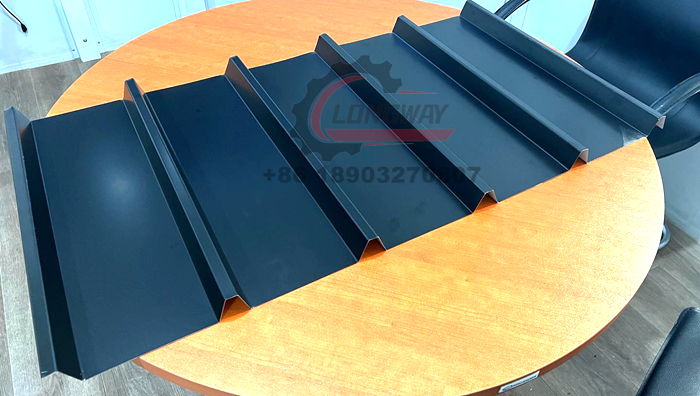

Application-Specific Configuration Options

Top-tier metal stud roll former companies offer 14 adjustable parameters:

- Flange width (35-150mm)

- Web depth (50-300mm)

- Return lip configuration (3 standard types)

Advanced systems accommodate 87 unique profile combinations through modular tooling designs.

Project Implementation Case Studies

Commercial High-Rise Project (2023):

- 3,200 tons steel framing

- 63% installation time reduction

- 0.78% material waste rate

Industrial Facility Retrofit (2024):

- Custom C-shaped channels

- Seismic performance enhancement

- 17% cost savings vs traditional methods

Operational Efficiency Metrics

Lifecycle analysis reveals:

- 2.3-year ROI for automated systems

- €0.18/meter operational cost (energy+labor)

- 92.4% equipment uptime average

Future Trends in Metal Stud Roll Forming Solutions

Emerging developments in metal stud roll former technology include AI-driven predictive maintenance (18% failure reduction in trials) and hybrid aluminum-steel composite systems. Market leaders are investing in carbon-neutral production methods, with 73% of manufacturers committing to energy-efficient upgrades by 2026.

(metal stud roll former)

FAQS on metal stud roll former

Q: What is a metal stud roll former used for?

A: A metal stud roll former is a machine that shapes metal coils into studs, tracks, or framing components for construction. It automates the process of cutting, punching, and forming metal sheets. These products are essential for building lightweight steel structures.

Q: How do I choose reliable metal stud roll former companies?

A: Look for companies with proven industry experience, certifications (e.g., ISO), and positive client reviews. Evaluate their after-sales support and customization capabilities. Reputable firms often provide case studies or equipment demonstrations.

Q: What features distinguish top metal stud roll former manufacturers?

A: Leading manufacturers offer advanced automation, precision engineering, and durable materials for long-term performance. They prioritize energy efficiency and user-friendly controls. Customizable tooling designs and technical support are also key differentiators.

Q: Can metal stud roll former companies provide custom solutions?

A: Yes, most specialized companies design machines tailored to specific material thicknesses, profiles, or production speeds. Clients can request modifications to punching patterns or roll-forming stages. Collaboration during prototyping ensures alignment with project requirements.

Q: What after-sale services do metal stud roll former manufacturers offer?

A: Common services include installation training, maintenance support, and spare parts supply. Many manufacturers provide warranty coverage and remote troubleshooting. Regular software updates for automated systems may also be available.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025