Φεβ . 16, 2025 01:22

Back to list

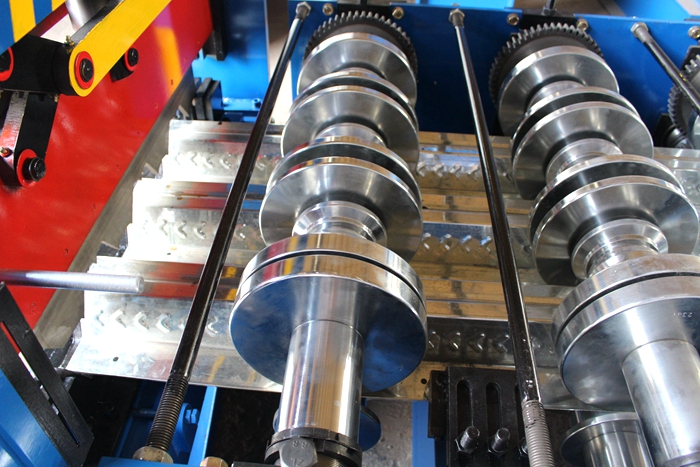

corrugated iron roofing roll forming machine

For those in the construction or manufacturing industries, sourcing high-quality corrugated iron roofing is crucial for project success. This need has propelled the corrugated iron roofing roll forming machine to the forefront of industrial equipment selections. As one navigates the detailed nuances of choosing the correct machinery, a comprehensive understanding of the equipment's operation and benefits brings assured expertise and facilitates informed decision-making.

The authority of a manufacturer can significantly influence the purchasing decision, underscoring the importance of sourcing from a reputable supplier. Established manufacturers often boast extensive research and development capabilities, resulting in advanced features such as quick-change tooling and programmable logic controllers (PLC) for better control and adaptability to different production requirements. Their known reliability provides peace of mind and strengthens the overall operational process, reassuring users that their investment will yield a high return. Trustworthiness involves assessed performance over time and across different conditions. When selecting a corrugated iron roofing roll forming machine, potential buyers are advised to seek reviews and testimonials that speak to the machine's consistency and adaptability. Several companies offer trial executions, allowing potential users to witness firsthand the machine's capability to produce varying corrugation angles and depths. This opportunity to evaluate performance ensures a trustworthy investment and fosters long-term business relationships. A thorough examination of the machine's maintenance requirements and support services further aligns with the trust factor. Knowledgeable suppliers understand the value of offering comprehensive after-sales support, including readily available spare parts and responsive customer service to address technical issues swiftly. This commitment solidifies confidence in the machinery's performance and ensures ongoing productivity. In conclusion, a corrugated iron roofing roll forming machine stands as an indispensable asset in the realm of metal forming, emphasizing the need for seasoned experience, product expertise, manufacturing authority, and unwavering trust. By prioritizing these elements in procurement decisions, industry professionals can create resilient, high-quality roofing solutions that meet diverse architectural demands while optimizing operational efficiency.

The authority of a manufacturer can significantly influence the purchasing decision, underscoring the importance of sourcing from a reputable supplier. Established manufacturers often boast extensive research and development capabilities, resulting in advanced features such as quick-change tooling and programmable logic controllers (PLC) for better control and adaptability to different production requirements. Their known reliability provides peace of mind and strengthens the overall operational process, reassuring users that their investment will yield a high return. Trustworthiness involves assessed performance over time and across different conditions. When selecting a corrugated iron roofing roll forming machine, potential buyers are advised to seek reviews and testimonials that speak to the machine's consistency and adaptability. Several companies offer trial executions, allowing potential users to witness firsthand the machine's capability to produce varying corrugation angles and depths. This opportunity to evaluate performance ensures a trustworthy investment and fosters long-term business relationships. A thorough examination of the machine's maintenance requirements and support services further aligns with the trust factor. Knowledgeable suppliers understand the value of offering comprehensive after-sales support, including readily available spare parts and responsive customer service to address technical issues swiftly. This commitment solidifies confidence in the machinery's performance and ensures ongoing productivity. In conclusion, a corrugated iron roofing roll forming machine stands as an indispensable asset in the realm of metal forming, emphasizing the need for seasoned experience, product expertise, manufacturing authority, and unwavering trust. By prioritizing these elements in procurement decisions, industry professionals can create resilient, high-quality roofing solutions that meet diverse architectural demands while optimizing operational efficiency.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products