The Role of Deck Roll Forming Machines in Modern Construction

Deck roll forming machines have become an integral part of modern construction, enabling faster, more efficient, and cost-effective production of metal decks for roofs and floors. These machines, known for their precision and versatility, have significantly reshaped the way construction projects are approached. Their impact is seen across both commercial and residential developments, where time, cost, and quality are of paramount importance. In this article, we will explore how deck roll forming machines are transforming the construction industry and why they have become a staple in the building process.

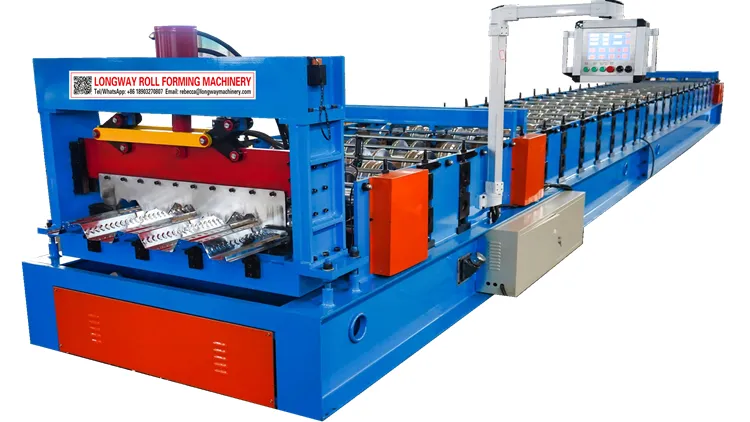

Streamlining Construction Processes with Precision About Deck Roll Forming Machines

One of the primary advantages of using metal deck roll forming machine in modern construction is the precision with which they create metal deck profiles. These machines are capable of producing highly accurate, uniform decking materials that meet specific structural requirements. In traditional methods of decking production, achieving consistent quality across large volumes could be challenging and time-consuming. However, with deck roll forming technology, the process is automated, ensuring that each panel is manufactured to precise measurements.

The accuracy of these machines contributes not only to the structural integrity of the building but also to reducing material waste. As construction projects often involve strict timelines and budgets, minimizing material waste is crucial for maintaining cost efficiency. Deck floor roll forming machine, by producing exact measurements for each panel, contribute to a significant reduction in material wastage, ensuring that no resources are squandered during production.

Improving Speed and Efficiency in Construction With Deck Roll Forming Machines

Time is one of the most valuable assets in modern construction, and deck roll forming machines are designed to save time at multiple stages of the building process. The speed at which these machines operate allows for the rapid production of large quantities of metal decking, reducing overall project timelines. This is especially important in large-scale commercial and industrial projects where delays can be costly.

In addition to increasing production speed, deck roll forming machines offer the ability to produce custom designs at scale. Whether it is for a standard floor or a customized roof deck, the flexibility of these machines ensures that contractors can meet specific design requirements without needing to adjust their production processes significantly. This flexibility is a game-changer, allowing construction teams to focus on other aspects of the project while knowing that the decking component is being produced efficiently and on time.

Enhancing Durability and Safety of Structures With Deck Roll Forming Machines

Deck roll forming machines produce decking that is typically made from high-strength materials like steel and aluminum, offering exceptional durability. These materials provide superior strength-to-weight ratios, making them ideal for use in construction. Whether for residential buildings, commercial establishments, or even bridges, metal decks formed by these machines are designed to withstand the demands of modern construction.

Furthermore, the steel decks produced by roll forming machines are highly resistant to environmental factors such as corrosion, weathering, and temperature fluctuations. This enhanced durability reduces the need for frequent repairs and replacements, leading to long-term cost savings for building owners.

From a safety perspective, the consistency and strength of the decking produced by roll forming machines also contribute to the overall safety of the structure. A well-formed metal deck ensures that the building or structure can handle the loads it is designed to support, reducing the risk of structural failures over time.

Cost-Effectiveness and Competitive Advantage About Deck Roll Forming Machines

In addition to improving speed and quality, deck roll forming machines also offer significant cost benefits. Although the initial investment in these machines can be substantial, their long-term return on investment is undeniable. By improving efficiency, reducing material waste, and cutting labor costs, they help construction firms complete projects on time and within budget.

Furthermore, the ability to produce customized decking solutions means that contractors can cater to a broader range of projects, including those with unique design specifications. This flexibility in production enhances a company’s competitive edge in the marketplace, allowing them to bid on a wider variety of projects, from large commercial builds to niche residential designs.

Supporting Sustainable Building Practices With Deck Roll Forming Machines

Sustainability has become a critical focus in modern construction, and deck roll forming machines are contributing to these efforts in several ways. First, by reducing material waste during the manufacturing process, these machines help minimize the environmental impact of construction projects. Roll-forming also enables the use of recycled materials, as metal decks are highly recyclable, contributing to a more sustainable lifecycle for building components.

Moreover, the precision and strength of the decking produced by these machines mean that buildings can be constructed with a smaller environmental footprint while still maintaining high structural standards. As more construction companies embrace sustainability as a core value, deck roll forming machines play a key role in helping them meet these objectives.

Adaptability to Emerging Trends in Construction With Deck Roll Forming Machines

As construction trends evolve, so do the requirements for building materials. Deck roll forming machines are highly adaptable, making them capable of keeping up with the changing demands of the industry. One such trend is the increasing use of prefabricated and modular construction methods. Deck roll forming machines are well-suited to this approach, as they can produce large quantities of uniform decking components that can be pre-assembled off-site and then transported to the construction site.

In addition to modular construction, the rise of green buildings and eco-friendly designs also benefits from the capabilities of deck roll forming machines. As architects and engineers push for innovative designs that reduce environmental impact, these machines provide the necessary flexibility to create customized solutions for sustainable buildings.

-

Corrugated iron roofing sheet making machine with CE, AutoNachrichtNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNachrichtNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNachrichtNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNachrichtNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNachrichtNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNachrichtNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENachrichtNov.11, 2025