More Language

Untranslated

Feb . 20, 2025 03:01

Back to list

metal roof roll forming machine supplier

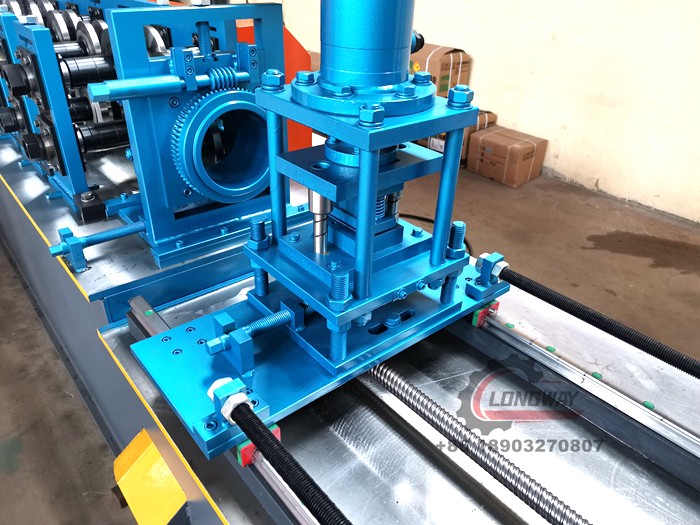

In the realm of modern construction, the choice of materials plays a pivotal role in both the economic efficiency and environmental impact of a project. One of the increasingly popular choices among contractors and builders is metal roofing, and when it comes to sourcing these materials efficiently, a metal roof roll forming machine supplier becomes essential. This article aims to provide an in-depth exploration of how selecting the right supplier for a metal roof roll forming machine can significantly enhance your business's operational efficiency and output quality.

Trustworthiness, while harder to quantify, is perhaps the most crucial factor when choosing a supplier. A trustworthy supplier is transparent about their processes, product limitations, and service agreements. They are prompt in addressing queries and concerns, which is indicative of their reliability. Customer testimonials and case studies are invaluable resources in assessing a supplier’s trustworthiness. They provide insight into the supplier’s ability to deliver on their promises and the quality of their customer service. Moreover, a supplier’s willingness to provide comprehensive training and support cannot be overstated. When investing in a metal roof roll forming machine, the assurance that your team will be adequately trained to operate it efficiently is indispensable. Comprehensive training programs provided by the supplier ensure that your operations remain uninterrupted and production timelines are met. Additionally, robust after-sales support, including maintenance and repair services, further cements the supplier's role as a valuable partner in business operations. In the ever-competitive world of construction, operational efficiency can significantly impact profitability. Metal roof roll forming machines, when sourced from a reputable supplier, streamline the production of high-quality roofing materials. This not only reduces overhead costs but also enhances the durability and aesthetic appeal of the final product. A proficient supplier offers machines that minimize energy consumption and material waste, aligning with the growing demand for sustainable construction practices. In conclusion, selecting a metal roof roll forming machine supplier is a strategic decision that should be approached with careful consideration of their experience, expertise, authoritativeness, and trustworthiness. The right supplier acts as a cornerstone of your production capabilities, enhancing not only the quality and reliability of your output but also your company’s reputation in the market. As the construction industry continues to evolve, partnering with a leading supplier who understands your needs and innovates continuously offers a competitive edge, ensuring your projects meet both current demands and future challenges.

Trustworthiness, while harder to quantify, is perhaps the most crucial factor when choosing a supplier. A trustworthy supplier is transparent about their processes, product limitations, and service agreements. They are prompt in addressing queries and concerns, which is indicative of their reliability. Customer testimonials and case studies are invaluable resources in assessing a supplier’s trustworthiness. They provide insight into the supplier’s ability to deliver on their promises and the quality of their customer service. Moreover, a supplier’s willingness to provide comprehensive training and support cannot be overstated. When investing in a metal roof roll forming machine, the assurance that your team will be adequately trained to operate it efficiently is indispensable. Comprehensive training programs provided by the supplier ensure that your operations remain uninterrupted and production timelines are met. Additionally, robust after-sales support, including maintenance and repair services, further cements the supplier's role as a valuable partner in business operations. In the ever-competitive world of construction, operational efficiency can significantly impact profitability. Metal roof roll forming machines, when sourced from a reputable supplier, streamline the production of high-quality roofing materials. This not only reduces overhead costs but also enhances the durability and aesthetic appeal of the final product. A proficient supplier offers machines that minimize energy consumption and material waste, aligning with the growing demand for sustainable construction practices. In conclusion, selecting a metal roof roll forming machine supplier is a strategic decision that should be approached with careful consideration of their experience, expertise, authoritativeness, and trustworthiness. The right supplier acts as a cornerstone of your production capabilities, enhancing not only the quality and reliability of your output but also your company’s reputation in the market. As the construction industry continues to evolve, partnering with a leading supplier who understands your needs and innovates continuously offers a competitive edge, ensuring your projects meet both current demands and future challenges.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products