Feb . 16, 2025 07:50

Back to list

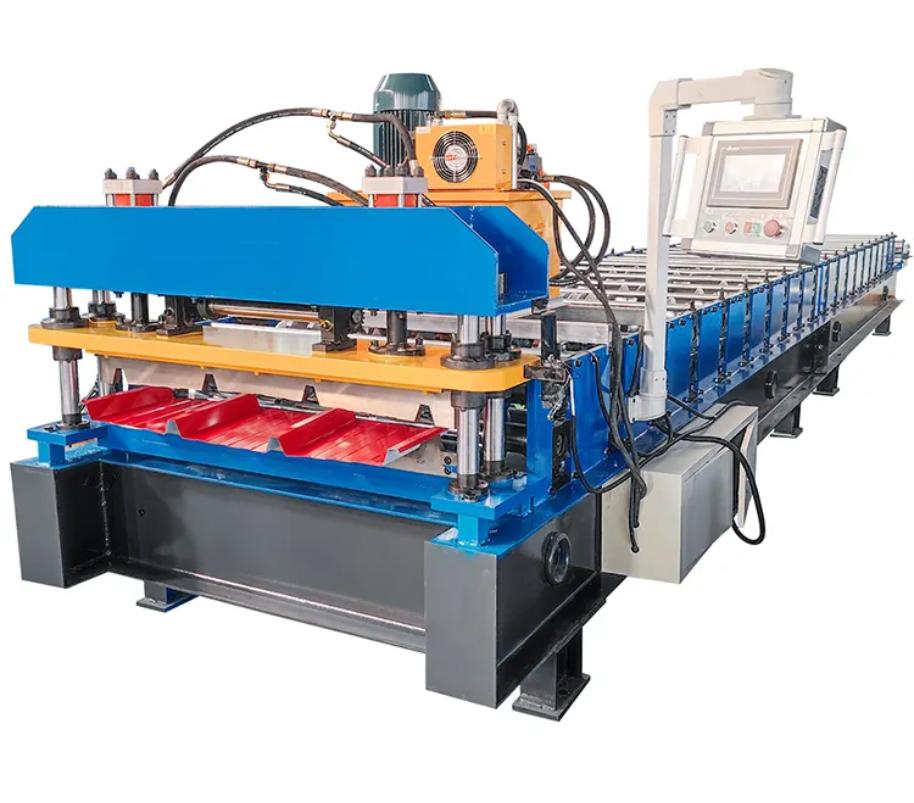

customized double layer roll forming machine

In the ever-evolving landscape of industrial manufacturing, the customized double layer roll forming machine stands as a testament to both innovation and precision. As industries demand more specialized equipment to meet unique production requirements, the need for customization in machinery has become increasingly critical. These roll forming machines are not only transforming how products are manufactured but are also setting a precedent for future technological advancements.

Trustworthiness in the realm of customized double layer roll forming machines is cultivated through transparency and reliability. Suppliers who offer comprehensive warranties, detailed documentation, and efficient customer support build long-term relationships with their clients. Furthermore, they often collaborate closely with clients during the initial design phase to ensure the machine will meet all operational requirements. This level of customer service, coupled with robust post-installation support, ensures clients feel secure in their investment, confident that they will receive ongoing support and that their equipment will continue to meet their production needs over time. Moreover, the adaptability of these machines allows businesses to stay competitive by accommodating future changes in production demands without the need for additional investments in new machinery. The capacity to integrate these machines with existing systems or to modify them to suit new products or processes offers invaluable flexibility. As companies expand or shift focus, having adaptable equipment that can keep pace with change is a critical business advantage. In conclusion, the customized double layer roll forming machine represents more than just a piece of industrial equipment; it embodies the integration of experience, expertise, authority, and trustworthiness. For industries dedicated to precision and efficiency, these machines not only meet existing production demands but also pave the way for future innovations. By investing in custom solutions, companies can project confidence in their manufacturing capabilities, ensuring they remain at the forefront of industry advancements while delivering unparalleled product quality to their clients.

Trustworthiness in the realm of customized double layer roll forming machines is cultivated through transparency and reliability. Suppliers who offer comprehensive warranties, detailed documentation, and efficient customer support build long-term relationships with their clients. Furthermore, they often collaborate closely with clients during the initial design phase to ensure the machine will meet all operational requirements. This level of customer service, coupled with robust post-installation support, ensures clients feel secure in their investment, confident that they will receive ongoing support and that their equipment will continue to meet their production needs over time. Moreover, the adaptability of these machines allows businesses to stay competitive by accommodating future changes in production demands without the need for additional investments in new machinery. The capacity to integrate these machines with existing systems or to modify them to suit new products or processes offers invaluable flexibility. As companies expand or shift focus, having adaptable equipment that can keep pace with change is a critical business advantage. In conclusion, the customized double layer roll forming machine represents more than just a piece of industrial equipment; it embodies the integration of experience, expertise, authority, and trustworthiness. For industries dedicated to precision and efficiency, these machines not only meet existing production demands but also pave the way for future innovations. By investing in custom solutions, companies can project confidence in their manufacturing capabilities, ensuring they remain at the forefront of industry advancements while delivering unparalleled product quality to their clients.

Latest news

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

Related Products