Oca . 22, 2025 02:53

Back to list

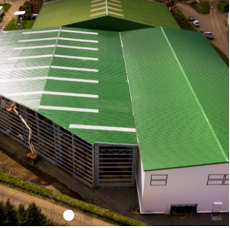

corrugated iron roofing sheet making machine

The demand for corrugated iron machines has significantly surged in the construction and manufacturing industries, driven by the necessity for efficient, durable, and cost-effective solutions. These machines have revolutionized the way industries approach metal forming, providing an unparalleled blend of craftsmanship and functionality. Understanding the intricacies of corrugated iron machines is crucial for businesses wanting to leverage their productivity, and doing so requires a comprehensive grasp of their operation, technological advancements, and application benefits.

Experience with corrugated iron machines also underscores the significance of customization. Different projects demand different specifications, whether it’s the curvature of the corrugations or the grade of the steel employed. By offering tailored solutions, businesses can meet specific client needs, ranging from architectural designs to niche industrial requirements. An in-depth understanding of the material science behind the metals and the mechanical processes involved empowers businesses to offer exclusive, bespoke solutions that differentiate them from competitors. The trustworthiness in a company utilizing corrugated iron machines is further enhanced by transparent communication with clients. Offering insights into material choices, explaining the reasoning behind design decisions, and setting realistic timelines can bridge the trust gap between supplier and client. In the digital age, leveraging online platforms to share customer testimonials and case studies further bolsters a business’s reputation. A particularly effective strategy is showcasing before-and-after scenarios that demonstrate the transformative impact of using corrugated iron in construction projects. For businesses looking to invest in a corrugated iron machine, considerations should include the machine’s capacity, speed, ease of operation, and energy efficiency. It’s not enough to have the latest technology; it’s essential to have technology that integrates well with existing systems and offers scalable solutions for future expansion. Partnering with reputable manufacturers who provide robust after-sales support and training modules ensures that businesses can maximize the potential of their investment. In conclusion, corrugated iron machines stand at the forefront of modern manufacturing, embodying a synthesis of technological prowess and industrial necessity. By harnessing the full potential of these machines through diligent maintenance, adherence to standards, and commitment to transparency, businesses can not only optimize their production processes but also solidify their standing in the market. As industries continue to evolve, the role of corrugated iron machines will undeniably grow, marking a significant leap forward in sustainable and efficient industrial practices.

Experience with corrugated iron machines also underscores the significance of customization. Different projects demand different specifications, whether it’s the curvature of the corrugations or the grade of the steel employed. By offering tailored solutions, businesses can meet specific client needs, ranging from architectural designs to niche industrial requirements. An in-depth understanding of the material science behind the metals and the mechanical processes involved empowers businesses to offer exclusive, bespoke solutions that differentiate them from competitors. The trustworthiness in a company utilizing corrugated iron machines is further enhanced by transparent communication with clients. Offering insights into material choices, explaining the reasoning behind design decisions, and setting realistic timelines can bridge the trust gap between supplier and client. In the digital age, leveraging online platforms to share customer testimonials and case studies further bolsters a business’s reputation. A particularly effective strategy is showcasing before-and-after scenarios that demonstrate the transformative impact of using corrugated iron in construction projects. For businesses looking to invest in a corrugated iron machine, considerations should include the machine’s capacity, speed, ease of operation, and energy efficiency. It’s not enough to have the latest technology; it’s essential to have technology that integrates well with existing systems and offers scalable solutions for future expansion. Partnering with reputable manufacturers who provide robust after-sales support and training modules ensures that businesses can maximize the potential of their investment. In conclusion, corrugated iron machines stand at the forefront of modern manufacturing, embodying a synthesis of technological prowess and industrial necessity. By harnessing the full potential of these machines through diligent maintenance, adherence to standards, and commitment to transparency, businesses can not only optimize their production processes but also solidify their standing in the market. As industries continue to evolve, the role of corrugated iron machines will undeniably grow, marking a significant leap forward in sustainable and efficient industrial practices.

Latest news

-

The Role of Hydraulic Systems in Sheet Metal SlittersNewsAug.23, 2025

-

Customization Options in Metal Deck Roll Forming MachinesNewsAug.23, 2025

-

Safety Tips When Using a Gutter Making MachineNewsAug.23, 2025

-

Key Components of a C Purlin Machine ExplainedNewsAug.23, 2025

-

Maintenance Tips for a Steel Angle Roll Forming MachineNewsAug.23, 2025

-

Portable Metal Roofing Machine Applications in Remote ConstructionNewsAug.23, 2025

-

Roof Panel MachineNewsAug.18, 2025

Related Products