Şub . 15, 2025 19:47

Back to list

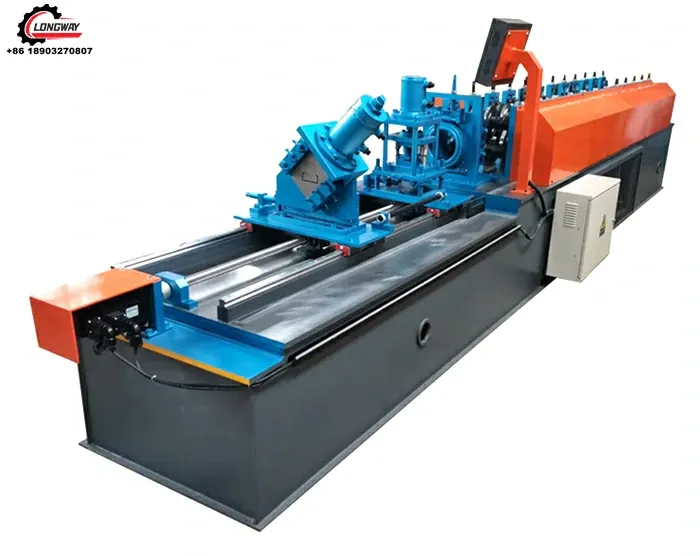

cold purling roll forming machine

In the rapidly evolving world of industrial machinery, the cold purling roll forming machine stands out as a highly specialized tool. This machine is essential for manufacturers seeking to create corrugated sheets and various profiles with precision and speed. Its increasing popularity is not just by chance; it's a direct result of its exceptional benefits and unparalleled efficiency in the production process.

From a sustainability perspective, cold purling roll forming machines are a smart choice. They generate significantly less waste compared to alternative methods. The precise forming process ensures minimal scrap production, promoting an eco-friendly production environment. Additionally, the energy consumption of these machines is considerably lower, aligning with global trends toward more sustainable manufacturing practices by reducing carbon footprints. When discussing expertise and authority in the field of industrial machinery, manufacturers and suppliers of cold purling roll forming machines often lead the conversation. These entities are at the forefront of research and development, continuously upgrading machine capabilities to meet evolving market demands. The credibility of these manufacturers is evident in their adherence to international quality standards and regulations, ensuring that the machinery not only performs optimally but also meets safety guidelines. For businesses, investing in a cold purling roll forming machine translates to a significant competitive advantage. It provides the capability to produce a higher volume of products in a shorter time frame without compromising on quality. This investment allows businesses to respond promptly to market needs, build a strong reputation for reliability and quality, and foster trust among clients and stakeholders. In conclusion, the cold purling roll forming machine embodies a harmonious blend of precision, efficiency, and adaptability. As an indispensable tool in the realm of industrial manufacturing, it assures high-quality production, cost-effectiveness, and sustainable practices. Its continued evolution reflects the industry's commitment to innovation and excellence, making it a trustworthy ally for manufacturers aiming to stay ahead in a competitive marketplace. As the construction and manufacturing sectors grow, the significance of these machines is only set to increase, assuring industry stakeholders of their strategic importance in modern manufacturing.

From a sustainability perspective, cold purling roll forming machines are a smart choice. They generate significantly less waste compared to alternative methods. The precise forming process ensures minimal scrap production, promoting an eco-friendly production environment. Additionally, the energy consumption of these machines is considerably lower, aligning with global trends toward more sustainable manufacturing practices by reducing carbon footprints. When discussing expertise and authority in the field of industrial machinery, manufacturers and suppliers of cold purling roll forming machines often lead the conversation. These entities are at the forefront of research and development, continuously upgrading machine capabilities to meet evolving market demands. The credibility of these manufacturers is evident in their adherence to international quality standards and regulations, ensuring that the machinery not only performs optimally but also meets safety guidelines. For businesses, investing in a cold purling roll forming machine translates to a significant competitive advantage. It provides the capability to produce a higher volume of products in a shorter time frame without compromising on quality. This investment allows businesses to respond promptly to market needs, build a strong reputation for reliability and quality, and foster trust among clients and stakeholders. In conclusion, the cold purling roll forming machine embodies a harmonious blend of precision, efficiency, and adaptability. As an indispensable tool in the realm of industrial manufacturing, it assures high-quality production, cost-effectiveness, and sustainable practices. Its continued evolution reflects the industry's commitment to innovation and excellence, making it a trustworthy ally for manufacturers aiming to stay ahead in a competitive marketplace. As the construction and manufacturing sectors grow, the significance of these machines is only set to increase, assuring industry stakeholders of their strategic importance in modern manufacturing.

Latest news

Related Products