Jan . 29, 2025 06:15

Back to list

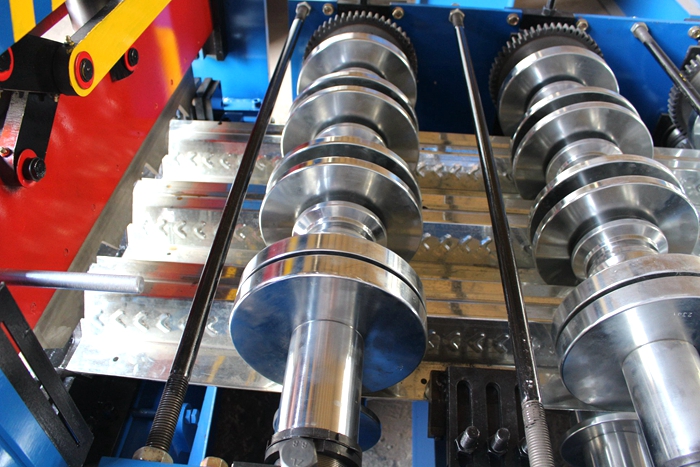

T18 C18 Metal roofing machine Roof sheet forming machine

Portable metal roll forming machines have revolutionized the metalworking industry, offering unmatched flexibility and efficiency for a wide range of applications. Sharing insights garnered from years of hands-on experience with these machines, this article aims to illuminate their intrinsic value, operational prowess, and the unparalleled benefits they present to professionals seeking precision and reliability in metal fabrication.

Trustworthiness and authoritativeness are further reinforced by industry endorsements and compliance with international standards, which are crucial for ensuring the safety and reliability of roll forming machines. High-quality portable roll formers typically carry certifications that attest to their adherence to rigorous engineering and safety standards, providing users with the assurance that these machines will perform reliably in demanding conditions. In operational terms, portable roll forming machines streamline the metal shaping process by minimizing material wastage and reducing the time required to achieve finished products. This efficiency translates into significant cost savings for businesses and contractors, enhancing their competitiveness in the market. Companies have reported increased profit margins by integrating portable roll formers into their production lines, largely attributed to reduced labor costs and maximized output. Moreover, maintenance of portable roll formers is generally straightforward, with many models designed for quick routine checks and part replacements. This practicality in maintenance underscores their sustained operation over time, often resulting in an impressive return on investment. From a long-term perspective, businesses that are diligent in machine maintenance can expect these portable units to deliver a durable and dependable service life, further justifying their initial investment. In conclusion, portable metal roll forming machines stand as a testament to advancements in metal fabrication technology, embodying a potent mix of experience-based usability, expert-level precision, authoritative certification, and trustworthiness. Their integration into metalworking practices not only bolsters operational efficiency but also empowers businesses with the tools necessary to innovate and excel in an increasingly competitive industrial landscape.

Trustworthiness and authoritativeness are further reinforced by industry endorsements and compliance with international standards, which are crucial for ensuring the safety and reliability of roll forming machines. High-quality portable roll formers typically carry certifications that attest to their adherence to rigorous engineering and safety standards, providing users with the assurance that these machines will perform reliably in demanding conditions. In operational terms, portable roll forming machines streamline the metal shaping process by minimizing material wastage and reducing the time required to achieve finished products. This efficiency translates into significant cost savings for businesses and contractors, enhancing their competitiveness in the market. Companies have reported increased profit margins by integrating portable roll formers into their production lines, largely attributed to reduced labor costs and maximized output. Moreover, maintenance of portable roll formers is generally straightforward, with many models designed for quick routine checks and part replacements. This practicality in maintenance underscores their sustained operation over time, often resulting in an impressive return on investment. From a long-term perspective, businesses that are diligent in machine maintenance can expect these portable units to deliver a durable and dependable service life, further justifying their initial investment. In conclusion, portable metal roll forming machines stand as a testament to advancements in metal fabrication technology, embodying a potent mix of experience-based usability, expert-level precision, authoritative certification, and trustworthiness. Their integration into metalworking practices not only bolsters operational efficiency but also empowers businesses with the tools necessary to innovate and excel in an increasingly competitive industrial landscape.

Latest news

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

Related Products