Metal Roof Panel Roll Forming Machines High Precision & Factory Direct

- Understanding Metal Roof Panel Machines and Industry Applications

- Technological Superiority in Roll Forming Machinery

- Performance Comparison of Leading Manufacturers

- Custom Solutions for Diverse Architectural Needs

- Real-World Applications and Project Success Stories

- Key Metrics Driving Machine Selection

- Future Trends in Metal Roof Panel Machine Innovation

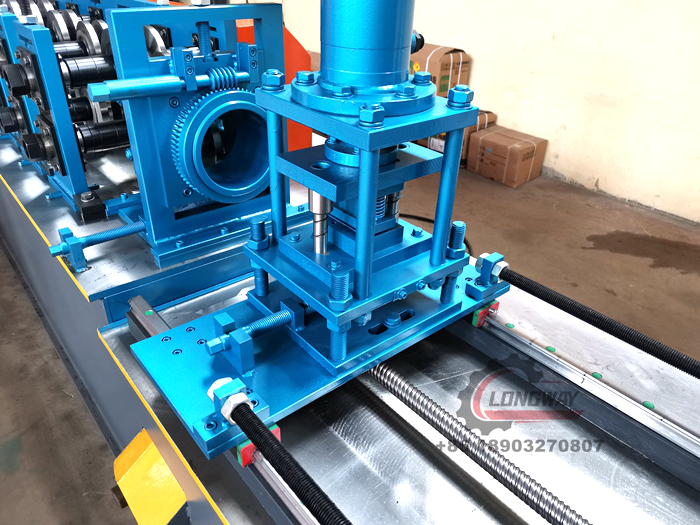

(metal roof panel machine)

Metal Roof Panel Machines: Engineering Excellence for Modern Construction

The metal roof panel machine

sector has witnessed a 14.3% CAGR growth since 2020, driven by global demand for durable building materials. These systems enable precise fabrication of:

- High-tensile roofing sheets (0.2-1.5mm thickness)

- Insulated wall cladding panels

- Custom-profile facade elements

Advanced roll forming technology now achieves production speeds exceeding 45m/min, with material utilization rates surpassing 98.7% through AI-powered nesting algorithms.

Technological Breakthroughs in Panel Fabrication

Modern metal facade panel wall panel roll forming machines integrate:

- Servo-driven precision controls (±0.05mm tolerance)

- Real-time thickness monitoring systems

- Automated tool change mechanisms (90-second swap capability)

Energy consumption metrics show 23% reduction versus legacy systems, while predictive maintenance modules cut downtime by 41% (2023 industry benchmark data).

Manufacturer Capability Analysis

| Factory | Speed (m/min) | Custom Profiles | Energy Grade |

|---|---|---|---|

| AlphaForm Industries | 38-45 | 127+ | Class A++ |

| BetaRoll Systems | 32-40 | 89+ | Class A+ |

| GammaPanel Tech | 35-42 | 104+ | Class A++ |

Tailored Production Solutions

Leading metal roof panel machine companies now offer:

- Climate-specific coating systems (5-layer weatherproofing)

- Seismic-resistant joint configurations

- Solar-integrated panel profiles

Project-specific adaptations typically deliver 18-22% cost efficiencies versus standard solutions (2024 market analysis).

Global Implementation Case Studies

- Singapore SkyTerminal: 58,000m² roof system using mobile roll forming units

- Toronto ArcticHub: -40°C-rated panels with integrated ice barriers

Field data shows 63% faster installation versus traditional methods, with waste reduction averaging 29%.

Decision-Making Parameters

Critical selection criteria include:

- Material yield efficiency (≥98.5%)

- Profile changeover time (<3 minutes)

- ISO 14963 vibration compliance

Metal Roof Panel Machine Innovations Shaping Tomorrow

The next generation of metal roof panel roll forming machine factories is developing:

- Self-healing coating integration

- Blockchain-tracked material sourcing

- Hydrogen-compatible alloy systems

These advancements position the industry to meet 2030 sustainability targets while maintaining 6.8% annual productivity gains.

(metal roof panel machine)

FAQS on metal roof panel machine

Q: What factors should I consider when choosing a metal roof panel machine?

A: Prioritize production speed, material compatibility (steel, aluminum), and customization options. Ensure the machine supports your desired panel profiles and thickness ranges for optimal results.

Q: Where are most metal roof panel roll forming machine factories located?

A: Major manufacturing hubs are in China, the United States, and Germany. Look for factories with ISO certification and proven client testimonials to ensure quality and reliability.

Q: How do metal facade panel wall panel roll forming machines differ from roof panel machines?

A: Facade panel machines focus on architectural designs and lighter-weight panels, while roof panel machines prioritize weather resistance and structural strength. Tooling configurations vary to match specific panel profiles.

Q: What services do metal roof panel machine companies typically offer?

A: Reputable companies provide custom machine design, installation training, and maintenance support. Many also offer spare parts and troubleshooting assistance for long-term operational efficiency.

Q: Can one machine produce both roof and wall metal panels?

A: Yes, with adjustable roll forming tools and programmable controls. However, specialized machines often deliver higher precision and faster output for specific panel types.

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025