Lajme

-

The main difference is that while rolling forces the metal to flow into a different shape, sheet metal forming works by causing deformation in the material overall, with minimal effect on the grain structure or the thickness of the material.Lexo më shumë

The main difference is that while rolling forces the metal to flow into a different shape, sheet metal forming works by causing deformation in the material overall, with minimal effect on the grain structure or the thickness of the material.Lexo më shumë -

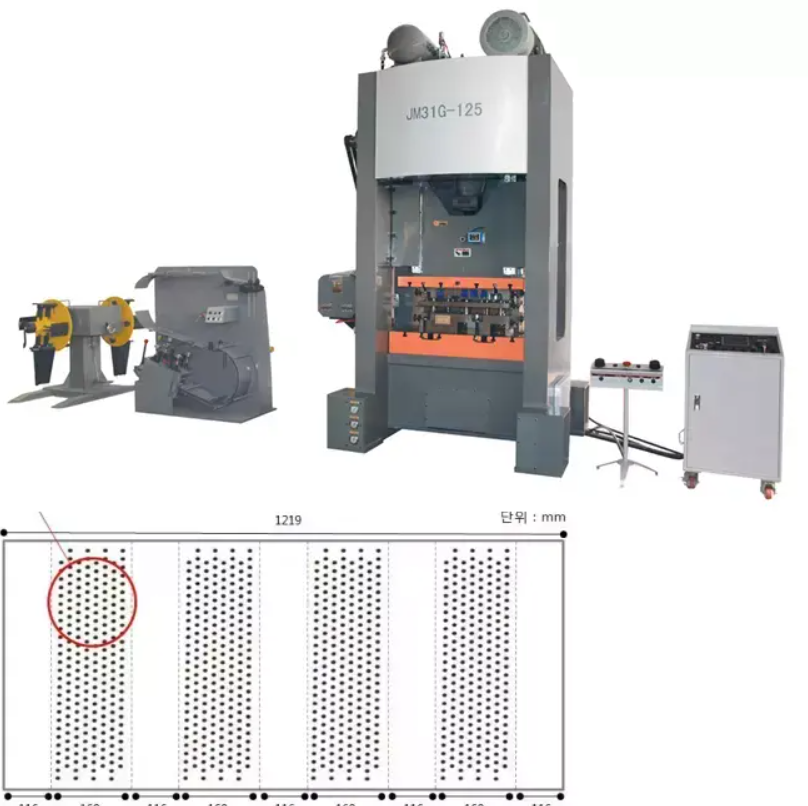

Tooling costs in manufacturing are already a sore spot for many purchasers, but some think roll form tooling is cost-prohibitive altogether. The up-front price tag tends to blind them to literal down-the-line savings. That’s right -- if your project fits, a roll form manufacturer can actually optimize your spending and get your parts out the door sooner and for less money per part.Lexo më shumë

Tooling costs in manufacturing are already a sore spot for many purchasers, but some think roll form tooling is cost-prohibitive altogether. The up-front price tag tends to blind them to literal down-the-line savings. That’s right -- if your project fits, a roll form manufacturer can actually optimize your spending and get your parts out the door sooner and for less money per part.Lexo më shumë -

IPlastic Injection Molding Machines Types and Benefitsnjection and extrusion molding are two popular plastic molding methods in the industrial and manufacturing sector that are used to make products with varying shapes and sizes. Depending on the product and the customer, both processes have their individual strengths. Midstate Mold & Engineering is strictly a plastic injection molding manufacturing company, but it is always helpful to our customers to know the difference between each process.Lexo më shumë

IPlastic Injection Molding Machines Types and Benefitsnjection and extrusion molding are two popular plastic molding methods in the industrial and manufacturing sector that are used to make products with varying shapes and sizes. Depending on the product and the customer, both processes have their individual strengths. Midstate Mold & Engineering is strictly a plastic injection molding manufacturing company, but it is always helpful to our customers to know the difference between each process.Lexo më shumë -

How do you determine what type of plastics manufacturer you should work with to design your custom plastic part? Forming plastic parts for industrial, commercial or medical uses requires different processes depending on the shape required and application of the product. Here’s the difference between plastic extrusion and injection molding.Lexo më shumë

How do you determine what type of plastics manufacturer you should work with to design your custom plastic part? Forming plastic parts for industrial, commercial or medical uses requires different processes depending on the shape required and application of the product. Here’s the difference between plastic extrusion and injection molding.Lexo më shumë -

The main difference between injection molding and extrusion molding is that injection molding is highly restrictive molding by injection mold, and extrusion is semi-restrictive molding by extrusion die.Lexo më shumë

The main difference between injection molding and extrusion molding is that injection molding is highly restrictive molding by injection mold, and extrusion is semi-restrictive molding by extrusion die.Lexo më shumë -

Blow moulding is a manufacturing process used for the production of plastic bottles, containers, and custom shapes. At Central Machinery and Plastic Products, we use extrusion blow moulding (EBM). EBM bottles are easily identifiable by their pinch line across the base of the bottle. This line is created as the mould cavity closes on the parison and the tail is trimmed off.Lexo më shumë

Blow moulding is a manufacturing process used for the production of plastic bottles, containers, and custom shapes. At Central Machinery and Plastic Products, we use extrusion blow moulding (EBM). EBM bottles are easily identifiable by their pinch line across the base of the bottle. This line is created as the mould cavity closes on the parison and the tail is trimmed off.Lexo më shumë -

Extrusion moulding is used to form plastic or metal materials into a pre-defined shape. During the process, the material is melted and pushed through an extrusion moulding machine, forming a long, tube-like shape or rod. This is cooled and cut to the required length. Often, extrusion moulding plastic products created in this way are used for wiring or insulating applications.The products’ cross-sections show uniformity throughout the length of the tubing, which is highly prized for numerous projects. Extrude plastics can also be formed into other tubular products, such as drinking straws. The plastic can also be shaped into thin sheeting or films by being flattened out by a set of cooling rolls.Lexo më shumë

Extrusion moulding is used to form plastic or metal materials into a pre-defined shape. During the process, the material is melted and pushed through an extrusion moulding machine, forming a long, tube-like shape or rod. This is cooled and cut to the required length. Often, extrusion moulding plastic products created in this way are used for wiring or insulating applications.The products’ cross-sections show uniformity throughout the length of the tubing, which is highly prized for numerous projects. Extrude plastics can also be formed into other tubular products, such as drinking straws. The plastic can also be shaped into thin sheeting or films by being flattened out by a set of cooling rolls.Lexo më shumë -

At an initial glance, extrusion and injection molding may appear to be very similar manufacturing processes. Both processes send molten material through machines to mass-produce low-cost parts of the desired shape. Both are a continuous production processes that amortizes costs as one orders higher quantities of parts. But, as we will see, these similarities quickly disappear when examining the differences between extrusion and injection molding.Lexo më shumë

At an initial glance, extrusion and injection molding may appear to be very similar manufacturing processes. Both processes send molten material through machines to mass-produce low-cost parts of the desired shape. Both are a continuous production processes that amortizes costs as one orders higher quantities of parts. But, as we will see, these similarities quickly disappear when examining the differences between extrusion and injection molding.Lexo më shumë -

How do you determine what type of plastics manufacturer you should work with to design your custom plastic part? Forming plastic parts for industrial, commercial or medical uses requires different processes depending on the shape required and application of the product. Here’s the difference between plastic extrusion and injection molding.Lexo më shumë

How do you determine what type of plastics manufacturer you should work with to design your custom plastic part? Forming plastic parts for industrial, commercial or medical uses requires different processes depending on the shape required and application of the product. Here’s the difference between plastic extrusion and injection molding.Lexo më shumë -

Extrusion moulding is used to form plastic or metal materials into a pre-defined shape. During the process, the material is melted and pushed through an extrusion moulding machine, forming a long, tube-like shape or rod. This is cooled and cut to the required length. Often, extrusion moulding plastic products created in this way are used for wiring or insulating applications.The products’ cross-sections show uniformity throughout the length of the tubing, which is highly prized for numerous projects. Extrude plastics can also be formed into other tubular products, such as drinking straws. The plastic can also be shaped into thin sheeting or films by being flattened out by a set of cooling rolls.Lexo më shumë

Extrusion moulding is used to form plastic or metal materials into a pre-defined shape. During the process, the material is melted and pushed through an extrusion moulding machine, forming a long, tube-like shape or rod. This is cooled and cut to the required length. Often, extrusion moulding plastic products created in this way are used for wiring or insulating applications.The products’ cross-sections show uniformity throughout the length of the tubing, which is highly prized for numerous projects. Extrude plastics can also be formed into other tubular products, such as drinking straws. The plastic can also be shaped into thin sheeting or films by being flattened out by a set of cooling rolls.Lexo më shumë -

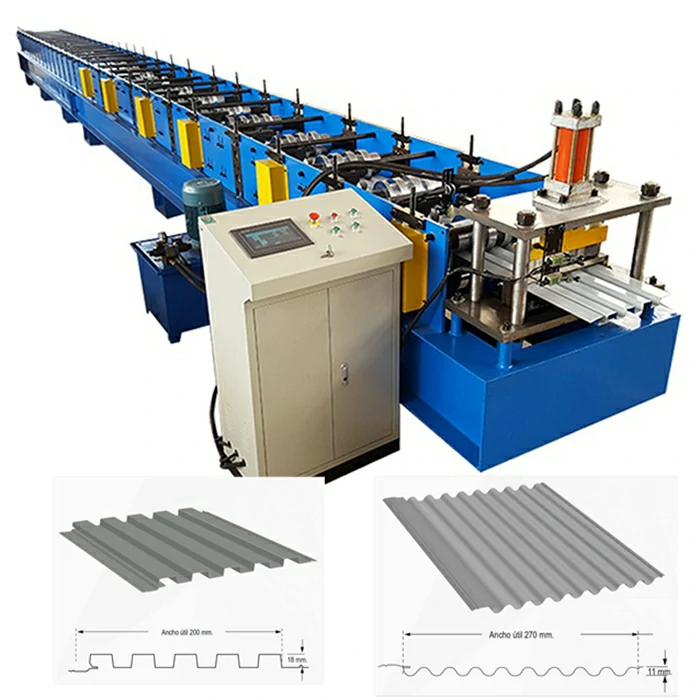

Roll forming machinery is a boon for both the quality and efficiency of metal fabrication. It allows for repeatable consistency within a product run, as well as versatility in design configurations and materials for metal parts. With wide-ranging applications from appliances and furniture to telecommunications and supports or frames for construction, this equipment produces large volumes of formed metal parts quickly, accurately, and affordably through consecutive bending stages.Lexo më shumë

Roll forming machinery is a boon for both the quality and efficiency of metal fabrication. It allows for repeatable consistency within a product run, as well as versatility in design configurations and materials for metal parts. With wide-ranging applications from appliances and furniture to telecommunications and supports or frames for construction, this equipment produces large volumes of formed metal parts quickly, accurately, and affordably through consecutive bending stages.Lexo më shumë -

Small-scale roll forming machines are specialized pieces of equipment making a big impact in cold-formed steel and construction — but are they worth it? Keep reading as we explain exactly how they work, plus the pros and cons, so you can make an informed decision if you’re considering a purchase.Lexo më shumë

Small-scale roll forming machines are specialized pieces of equipment making a big impact in cold-formed steel and construction — but are they worth it? Keep reading as we explain exactly how they work, plus the pros and cons, so you can make an informed decision if you’re considering a purchase.Lexo më shumë