Leading Manufacturers of Snap Lock Standing Seam Roll Forming Machines and Their Innovations

The Rise of Snap Lock Standing Seam Roll Forming Machines

In recent years, the construction and manufacturing industries have experienced a surge in demand for advanced building materials that are durable, efficient, and aesthetically pleasing. Among these innovations, snap lock standing seam roof systems have emerged as a popular choice, thanks to their remarkable weather resistance, energy efficiency, and sleek appearance. Central to this trend is the role of snap lock standing seam roll forming machines, which have become indispensable in the production of these roofing systems.

Understanding Snap Lock Standing Seam Roof Systems

Before diving into the machinery that produces these systems, it is crucial to understand what snap lock standing seam roofs are. This roofing type consists of long metal panels that are interlocked together, creating a seamless and watertight surface. The snap lock refers to the mechanism by which these panels are attached, allowing for easy installation and expansion, making them ideal for various climates and applications.

The advantages of snap lock standing seam roofs include their durability, resistance to wind uplift, and minimal maintenance requirements. Additionally, they can be crafted from various materials, such as steel, aluminum, or copper, which can be finished in a range of colors and textures to suit different architectural styles.

The Technology Behind Roll Forming Machines

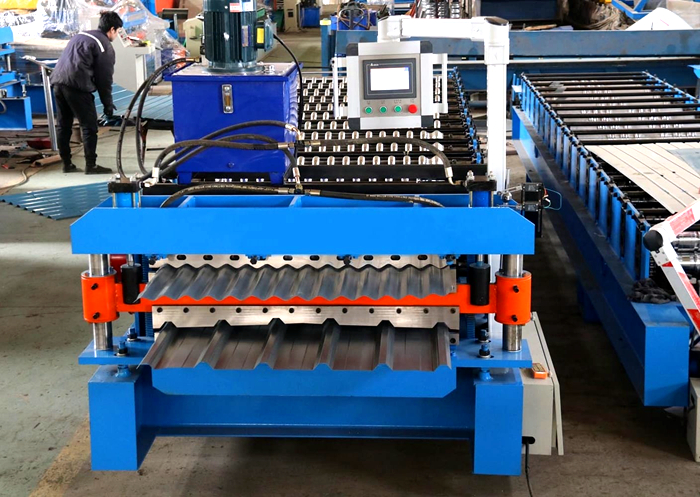

To produce snap lock standing seam roofing, manufacturers utilize specialized equipment known as roll forming machines. These machines are designed to reshape flat metal sheets into desired profiles through a series of progressive die stations. The roll forming process allows for the continuous production of long, uniform panels, which is essential for efficient construction.

Modern roll forming machines come equipped with various features, including computer numerical control (CNC) systems that ensure precision and repeatability. This technology allows manufacturers to produce panels with varying widths, heights, and profiles based on customer specifications. Furthermore, automation in roll forming machines enhances efficiency by reducing labor costs and minimizing material waste.

Key Players in the Industry

The market for snap lock standing seam roll forming machines has seen numerous companies emerging as key players. These manufacturers vary in size, capabilities, and geographical reach, providing different models of machinery to cater to a wide range of customer needs. Some notable companies in this field include

snap lock standing seam roll forming machine companies

1. Chen Hsong Group Known for its precision engineering, Chen Hsong offers customized roll forming solutions that meet the demands of the metal roofing market.

2. Zhongtuo Roll Forming Machine This company specializes in a variety of roll forming machines, including those for snap lock standing seam roofs. They emphasize quality control and innovative design in their manufacturing process.

3. Metform International With a strong global presence, Metform provides advanced roll forming technology, focusing on efficiency and sustainability in manufacturing.

4. Severance Tool Industries Known for their high-quality tooling and machinery, they offer solutions specifically geared toward producing metal roofing products.

5. Freiburg Machine Solutions This company is recognized for its engineering prowess and offers a range of customizable options for roll forming machines, including features that enhance production speed and product quality.

Future of Snap Lock Standing Seam Roll Forming Machines

As the construction industry moves towards using more sustainable materials and energy-efficient systems, the demand for snap lock standing seam roll forming machines is expected to grow. Innovations in technology, such as enhanced automation, smart controls, and improved materials, will likely shape the future of these machines.

Moreover, the rise of green building practices will drive companies to invest in roll forming technology that minimizes environmental impact. For example, machines that efficiently use energy and raw materials can not only enhance profitability but also align with the sustainable values of modern construction.

Conclusion

The evolution of snap lock standing seam roll forming machines highlights a significant trend in the construction industry. By providing manufacturers with the tools to create efficient, durable, and attractive roofing solutions, these machines are poised to meet the increasing demands for quality building materials. As technology advances and sustainability becomes a higher priority, the role of these machines will only solidify in the ever-evolving landscape of construction and manufacturing. With a strong foundation laid by key industry players, the future of snap lock standing seam roofs looks brighter than ever.

-

Understanding Steel Coil Cutting Machines and Their ImportanceNewsMay.16, 2025

-

The Essential Guide to Floor Deck Roll Forming MachinesNewsMay.16, 2025

-

Slitting Lines and Their BenefitsNewsMay.16, 2025

-

Sheet Metal Slitting Machines and Their OptionsNewsMay.16, 2025

-

Choosing the Best Downpipe Roll Forming MachinesNewsMay.16, 2025

-

5 Inch Gutter Machines: The Key to Efficient Gutter ProductionNewsMay.16, 2025

-

The Latest Trends in Cut to Length Equipment and MachinesNewsMay.09, 2025