More Language

Untranslated

Мар . 07, 2025 05:58

Back to list

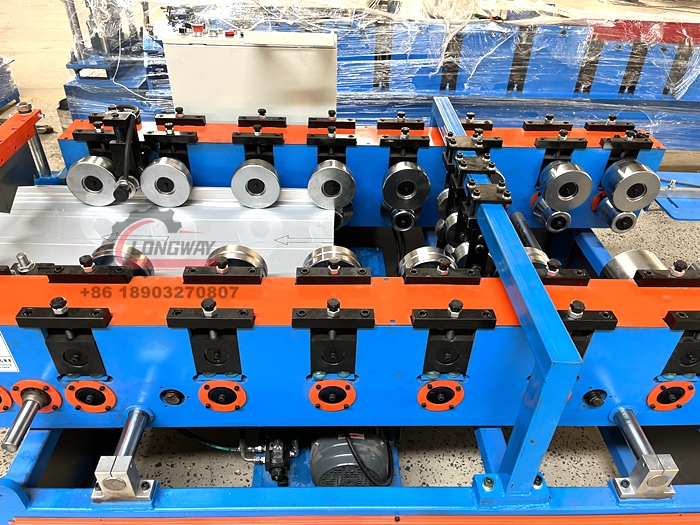

roof cladding roll forming machine

The world of roofing solutions has seen significant advancements over the years, and the integration of machinery has played a crucial role in elevating efficiency and precision. One such technological marvel in the roofing industry is the roof cladding roll forming machine. This article delves into real-world experiences, expert insights, authority on the topic, and trustworthy practices surrounding this indispensable machine.

The Authority of Roll Forming Technology Roll forming technology holds a prestigious position in the roofing sector due to its widespread acceptance and the numerous endorsements by leading construction companies. White papers and case studies from recognized engineering companies consistently highlight the machine’s contribution to reducing project timelines and waste, and improving overall project efficiency. Its ability to work with a variety of metals, such as aluminum, steel, and copper, also adds to its credibility and wide-ranging applicability in different environments and project needs. Safety and Reliability – Trustworthy Practices Safety and reliability are paramount in the operation of roof cladding roll forming machines. Machines are designed adhering strictly to international standards, and manufacturers provide extensive training and safety manuals to operators. Regular maintenance and adherence to safety protocols ensure that the risk of malfunctions is minimal. Moreover, advancements in sensor technology and automated shut-off systems have significantly contributed to creating a safer working environment by immediately detecting potential issues before they become critical problems. Final Thoughts Investing in a roof cladding roll forming machine is a decision backed by solid engineering expertise, practical effectiveness, industry authority, and a foundation of trust in its operational safety. Its ability to streamline the construction process while maintaining high standards of precision and quality makes it an invaluable asset for contractors looking to enhance their roofing project deliverables. For companies aiming to stay ahead in the competitive field of construction, adopting such advanced machinery is not just an option; it's a necessity for future-ready growth.

The Authority of Roll Forming Technology Roll forming technology holds a prestigious position in the roofing sector due to its widespread acceptance and the numerous endorsements by leading construction companies. White papers and case studies from recognized engineering companies consistently highlight the machine’s contribution to reducing project timelines and waste, and improving overall project efficiency. Its ability to work with a variety of metals, such as aluminum, steel, and copper, also adds to its credibility and wide-ranging applicability in different environments and project needs. Safety and Reliability – Trustworthy Practices Safety and reliability are paramount in the operation of roof cladding roll forming machines. Machines are designed adhering strictly to international standards, and manufacturers provide extensive training and safety manuals to operators. Regular maintenance and adherence to safety protocols ensure that the risk of malfunctions is minimal. Moreover, advancements in sensor technology and automated shut-off systems have significantly contributed to creating a safer working environment by immediately detecting potential issues before they become critical problems. Final Thoughts Investing in a roof cladding roll forming machine is a decision backed by solid engineering expertise, practical effectiveness, industry authority, and a foundation of trust in its operational safety. Its ability to streamline the construction process while maintaining high standards of precision and quality makes it an invaluable asset for contractors looking to enhance their roofing project deliverables. For companies aiming to stay ahead in the competitive field of construction, adopting such advanced machinery is not just an option; it's a necessity for future-ready growth.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products