Янв . 17, 2025 04:10

Back to list

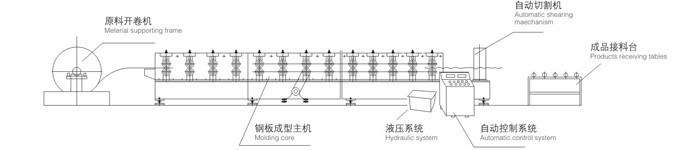

cladding roll forming machine

Cold roll forming is an innovative manufacturing process that involves the continuous bending of a long strip of sheet metal, typically coiled steel, into a desired cross-section. This process has been gaining traction for its numerous advantages and applications across diverse industries such as automotive, construction, and renewable energy sectors. To fully grasp the potential of cold roll forming, one must delve into its intricacies, real-world applications, and the expertise required to harness its full capabilities.

In terms of authoritativeness, cold roll forming is backed by a plethora of research and development from leading industrial institutes and universities. These research efforts are continuously expanding the potential uses and efficiencies of the process, ensuring that cold roll forming remains at the cutting edge of manufacturing technology. Industry conferences and publications are testament to ongoing advancements and shared discoveries, further establishing the authority of cold roll forming within the manufacturing sector. Building trust within the ecosystem of cold roll forming is connected to the transparency of processes and the reliability of the output. Manufacturers that prioritize quality control measures, such as ISO-certified production standards, routinely earn the trust of clients. Quality assurance processes are integrated at each step—from material selection and tool design to process execution and final product inspection—ensuring that each piece meets stringent safety and performance criteria. Case studies from trusted brands highlight the longevity, resilience, and aesthetic appeal of products manufactured using cold roll forming, solidifying client trust in the technology. In conclusion, cold roll forming is more than just a manufacturing process; it is a transformative approach in product development. By leveraging cold roll forming, industries gain access to a method that merges efficiency with superior product integrity. As industries strive for higher performance, reduced costs, and sustainable practices, cold roll forming emerges as a pivotal technology, backed by a wealth of experience, specialized expertise, authoritative research, and an unwavering commitment to trust and quality. This synergy positions cold roll forming as an irreplaceable asset in the modern manufacturing landscape, promising a future where innovation meets reliability.

In terms of authoritativeness, cold roll forming is backed by a plethora of research and development from leading industrial institutes and universities. These research efforts are continuously expanding the potential uses and efficiencies of the process, ensuring that cold roll forming remains at the cutting edge of manufacturing technology. Industry conferences and publications are testament to ongoing advancements and shared discoveries, further establishing the authority of cold roll forming within the manufacturing sector. Building trust within the ecosystem of cold roll forming is connected to the transparency of processes and the reliability of the output. Manufacturers that prioritize quality control measures, such as ISO-certified production standards, routinely earn the trust of clients. Quality assurance processes are integrated at each step—from material selection and tool design to process execution and final product inspection—ensuring that each piece meets stringent safety and performance criteria. Case studies from trusted brands highlight the longevity, resilience, and aesthetic appeal of products manufactured using cold roll forming, solidifying client trust in the technology. In conclusion, cold roll forming is more than just a manufacturing process; it is a transformative approach in product development. By leveraging cold roll forming, industries gain access to a method that merges efficiency with superior product integrity. As industries strive for higher performance, reduced costs, and sustainable practices, cold roll forming emerges as a pivotal technology, backed by a wealth of experience, specialized expertise, authoritative research, and an unwavering commitment to trust and quality. This synergy positions cold roll forming as an irreplaceable asset in the modern manufacturing landscape, promising a future where innovation meets reliability.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products