steel coil slitting

Understanding Steel Coil Slitting Process and Applications

Steel coil slitting is a critical manufacturing process that involves cutting wide rolls of steel coils into narrower strips, or slits, to meet specific requirements for various applications. This method is essential in the metal processing industry, allowing manufacturers to produce customized widths that can subsequently be used in a multitude of products, from automotive parts to construction materials.

The Slitting Process

The slitting process typically begins with a large coil of steel, which can vary in thickness, width, and alloy composition. The coil is unwound from a coil stand and passed through a series of rollers that ensure it remains flat and free from any defects. This initial preparation is crucial as even minor imperfections can lead to significant issues down the line.

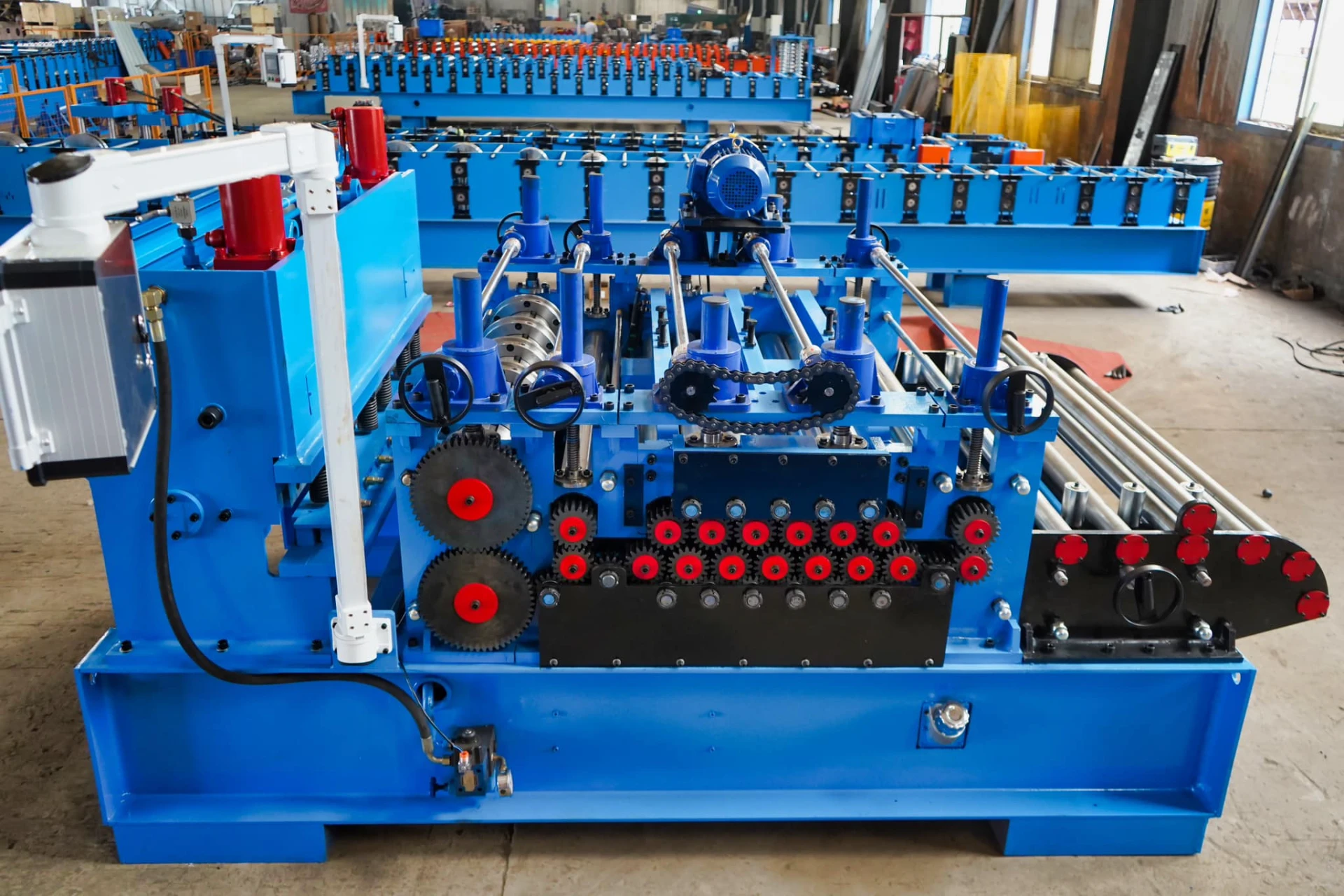

Once aligned correctly, the steel coil is fed into a slitting machine, where a series of sharp, circular knives cut the material into strips. The spacing between these knives determines the width of the final slits. Advanced slitting machines can accommodate multiple knives simultaneously, allowing for the efficient production of various widths in one cycle. As the slitting occurs, the individual strips are often guided and wound onto separate reels, creating manageable and easy-to-handle products.

Quality Control and Precision

Quality control is paramount in the slitting process. Manufacturers must ensure that each slit meets precise specifications regarding width, thickness, and surface finish. Tolerances are typically very tight, especially for applications that require specific properties such as ductility or strength. Various inspection techniques, including laser measurement systems and vision inspection, are employed to guarantee that the final product adheres to both industry standards and customer expectations.

steel coil slitting

Applications of Slit Steel Coils

The applications for slit steel coils are extensive and varied. One of the most significant industries utilizing this process is the automotive sector, where slit coils are used to produce components such as chassis parts, brackets, and structural supports. The light-weighting trend in automotive design has spurred demand for specific steel grades, necessitating precise slitting to achieve cost-effective components while ensuring strength and safety.

In the construction industry, slit steel coils are utilized for fabricating roofing and siding materials, reinforcing bars, and other structural elements. The ability to obtain specific widths allows construction firms to customize their supply chains, reducing waste and improving project turnaround times. Additionally, industries such as appliance manufacturing, HVAC, and furniture production also benefit from the versatility of slit steel coils in various fittings and frameworks.

Technological Advancements

Recent advancements in cutting technology and automation have significantly improved the efficiency of the slitting process. High-speed, computerized slitting machines now offer features such as automatic knife adjustments and real-time quality monitoring. These innovations not only streamline the production process but also enhance precision, allowing manufacturers to remain competitive in a demanding marketplace.

Conclusion

Steel coil slitting is a vital process that plays an integral role in various industries requiring high-quality steel products. With its ability to meet specific customer needs through precision cutting, the slitting process continues to evolve alongside technological advancements, ensuring efficiency and quality. As industries grow and adapt, the demand for customized steel strips will only increase, solidifying the importance of steel coil slitting in the manufacturing landscape.

-

Optimizing Your Production with CZ Purlin MachinesNewsMay.19, 2025

-

Maximizing Efficiency with C and U Channel Roll Forming MachinesNewsMay.19, 2025

-

Investing in Z Purlin MachinesNewsMay.19, 2025

-

Efficient Solutions with Metal Stud and Track Roll Forming MachinesNewsMay.19, 2025

-

Choosing the Best C Purlin MachinesNewsMay.19, 2025

-

Boost Your Production with Wall Angle Roll Forming MachinesNewsMay.19, 2025

-

Understanding Steel Coil Cutting Machines and Their ImportanceNewsMay.16, 2025