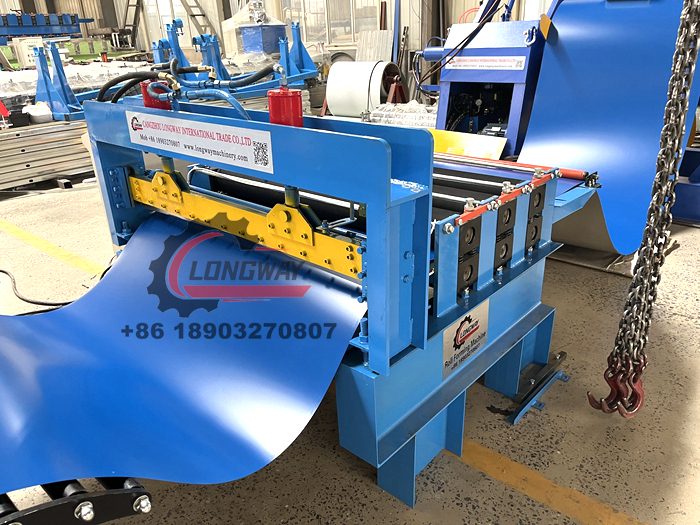

standing seam roll forming machine

Exploring the Benefits of Standing Seam Roll Forming Machines

Standing seam roofing systems have gained popularity in recent years due to their durability, energy efficiency, and aesthetic appeal. Central to the production of these systems is the standing seam roll forming machine, a specialized piece of equipment designed to create high-quality metal roofing panels. This article explores the advantages and features of standing seam roll forming machines, as well as their impact on the construction industry.

Standing seam roofs consist of vertically oriented panels that are connected by raised seams, which are securely fastened and not exposed to the elements. This design allows for excellent water drainage and minimizes the risk of leaks. The process of manufacturing these panels involves the use of a roll forming machine, which continuously bends a flat metal coil into the desired shape, creating panels with precise dimensions.

One of the primary advantages of standing seam roll forming machines is their efficiency

. These machines are capable of producing large quantities of roofing panels rapidly, significantly reducing labor costs and production time. Automated systems can be tailored to produce panels of varying widths and profiles, allowing manufacturers to meet diverse client needs without the expense of multiple machinery setups.standing seam roll forming machine

Additionally, modern standing seam roll forming machines incorporate advanced technologies such as computerized controls and real-time monitoring. These features enable manufacturers to maintain tight tolerances and ensure product quality throughout the production process. Furthermore, the machines can be programmed to deliver customized lengths, enhancing the flexibility and versatility of the production capabilities.

Another significant benefit is the material efficiency these machines offer. Roll forming minimizes waste by utilizing the entire metal coil, as opposed to cutting large sheets into smaller pieces. This not only reduces material costs but also contributes to more sustainable manufacturing practices. Given the increasing demand for eco-friendly construction solutions, the ability to produce sustainable roofing options is a valuable asset for metal roofing manufacturers.

Moreover, standing seam roofing systems are known for their long lifespan and low maintenance requirements. By investing in roll forming machines, manufacturers can produce high-quality panels that offer exceptional durability and performance. This longevity translates into greater customer satisfaction, as builders and homeowners alike value the reliability of standing seam roofs.

In conclusion, standing seam roll forming machines are essential in the production of modern roofing solutions that combine durability, efficiency, and aesthetic appeal. As the construction industry continues to evolve, the demand for high-quality, customizable, and sustainable roofing options is likely to grow. Manufacturers that leverage the capabilities of roll forming technology will not only enhance their operational efficiency but also meet the diverse needs of an increasingly discerning market. With the right machinery, the future of metal roofing looks promising.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025