High-Quality Stainless Steel Slitting Machines for Precision Cutting

Stainless Steel Slitting Machine Revolutionizing Metal Processing

In the realm of metal processing, stainless steel slitting machines play a pivotal role in enhancing efficiency and precision. These specialized machines are designed to cut stainless steel sheets into narrower strips with remarkable accuracy, catering to various industries such as automotive, construction, and appliances. As the demand for stainless steel products continues to rise, the importance of slitting machines in manufacturing processes cannot be overstated.

What is a Stainless Steel Slitting Machine?

A stainless steel slitting machine is a heavy-duty piece of industrial equipment that slices large coils of stainless steel into smaller widths. This process is essential for producing strips that meet specific customer requirements or fit specific applications. The machine operates with a series of rotary blades that cut through the steel with speed and precision, minimizing waste and maximizing productivity.

Key Features and Technologies

Modern stainless steel slitting machines are equipped with advanced technologies and features that enhance their performance

. These may include1. Auto-Feeding Systems Many slitting machines come with automatic feeding mechanisms that ensure a continuous and steady flow of material. This feature reduces manual labor and increases operational efficiency.

2. High-Precision Cutting With laser alignment and digital controls, these machines achieve exact cutting measurements, resulting in uniform strips that meet strict tolerances. This precision is crucial for industries where even a small deviation can lead to considerable issues.

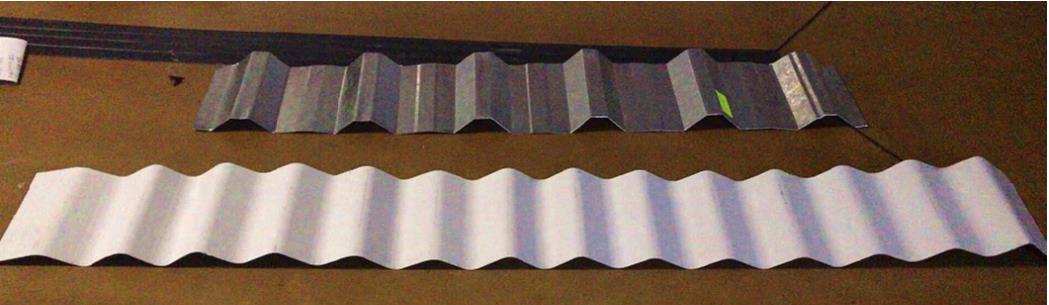

stainless steel slitting machine

3. Waste Management Systems Advanced slitting machines often include integrated waste management systems that optimize the collection and recycling of scrap material. This not only helps in reducing operational costs but also promotes sustainability in metal processing.

4. Adjustable Slitting Blades The ability to easily adjust the slitting blades allows operators to change the width of the cut quickly. This adaptability is essential for businesses that need to meet varying customer specifications.

Benefits of Using Stainless Steel Slitting Machines

The advantages of using stainless steel slitting machines are numerous. First and foremost, they enhance productivity by speeding up the cutting process, allowing manufacturers to fulfill larger orders within shorter timeframes. Additionally, the high degree of accuracy achieved by these machines ensures that the end products are of superior quality, helping companies maintain their reputation in competitive markets.

Moreover, slitting machines contribute to cost savings. By maximizing material use and reducing waste, businesses can significantly lower their production costs. The automation and efficiency of these machines also reduce labor requirements, further translating into financial benefits.

Conclusion

As industries worldwide strive for higher efficiency and quality, the role of stainless steel slitting machines becomes increasingly vital. The combination of advanced technology, precision cutting, and waste management makes these machines indispensable in the metal processing sector. With the ongoing innovations in this field, manufacturers can expect even greater improvements in performance and capabilities, cementing the importance of slitting machines in the future of metal production. Whether for large-scale manufacturing or specialized projects, investing in a stainless steel slitting machine can provide businesses with a significant competitive edge.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025