Optimizing Efficiency in the Steel Slitting Process for Enhanced Production Quality

Understanding Slitting Lines An Essential Tool in Metal Processing

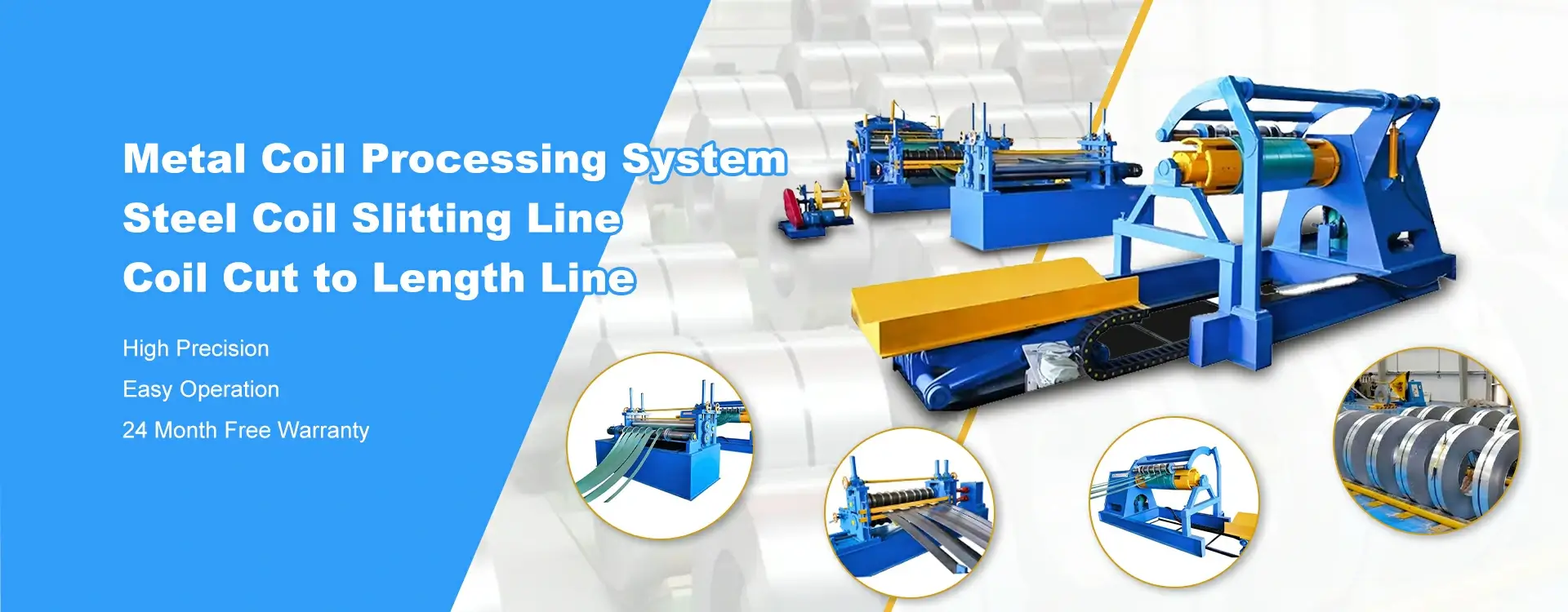

In the world of metal processing, efficiency and precision are paramount. Among the various methodologies employed to transform raw metal into usable products, slitting lines have emerged as a crucial technology for various industries. These automated systems play a vital role in cutting wide metal coils into narrower strips, which can then be further processed or used in manufacturing.

A slitting line typically consists of a series of components designed to achieve uniform strips with exact specifications. Initially, a large coil of metal is fed into the slitting line. This coil, often made of steel, aluminum, or other alloys, is uncoiled and passed through a series of rotating knives. These knives are set to precise widths, allowing for accurate cuts. As the metal passes through, it is sheared into narrower coils, which are then recoiled onto smaller spools automatically.

The precision of slitting lines can significantly affect the quality of the end product. Factors such as blade sharpness, speed settings, and feed rates play a critical role in determining the thickness and accuracy of the strips produced. Manufacturers must meticulously maintain their slitting lines, ensuring that all components are functioning optimally to reduce waste and improve production rates.

Moreover, slitting lines are equipped with various features that increase their versatility and efficiency

. For instance, many modern slitting lines incorporate automated systems for coil handling and inspection. This not only reduces the need for manual labor but also enhances safety and allows for real-time quality assurance. With advanced sensors and monitoring systems in place, operators can quickly identify and rectify any issues that may arise during the slitting process.slitting line

One of the significant advantages of using slitting lines is the ability to generate a variety of strip widths from a single metal coil. This flexibility allows manufacturers to cater to diverse client needs. From automotive parts to construction materials, the application of slitted strips is vast. In industries where specifications are critical, such as aerospace and automotive, the precision offered by slitting lines ensures that components meet stringent quality standards.

In addition to precision and versatility, slitting lines contribute to cost efficiency. By optimizing the cutting process and reducing material waste, manufacturers can lower production costs while increasing output. This is particularly important in today’s competitive market, where margins are often tight, and the demand for high-quality products continues to rise. Furthermore, with the push for sustainability, utilizing a slitting line helps in minimizing scrap and improving the overall environmental footprint of the manufacturing process.

The evolution of slitting technology has also been significant in recent years. With advancements in automation and digital monitoring, slitting lines have become more sophisticated. The integration of Industry 4.0 principles, such as IoT (Internet of Things), allows for more intelligent production processes, where machines can communicate, analyze data, and adapt in real-time to maintain optimal performance.

In conclusion, slitting lines have revolutionized the metal processing industry by providing a means to cut wide coils into precise strips efficiently and effectively. Their role in ensuring product quality, facilitating customization, and boosting production efficiency cannot be overstated. As technology continues to advance, slitting lines will undoubtedly become even more integral to the manufacturing landscape, enhancing productivity and meeting the evolving needs of various sectors. The future of metal processing remains bright, with slitting lines at the forefront of this transformation.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025