Metal Deck Roll Forming Equipment for Efficient Construction Solutions and Enhanced Strength

Metal Deck Roll Forming Machine Revolutionizing Construction and Architecture

In the realm of modern construction, efficiency, durability, and cost-effectiveness are key factors driving the choice of materials and manufacturing methods. Among the innovations that have significantly transformed the industry is the metal deck roll forming machine. This advanced technology streamlines the production of high-quality metal decking used in commercial buildings, warehouses, and industrial structures.

What is a Metal Deck Roll Forming Machine?

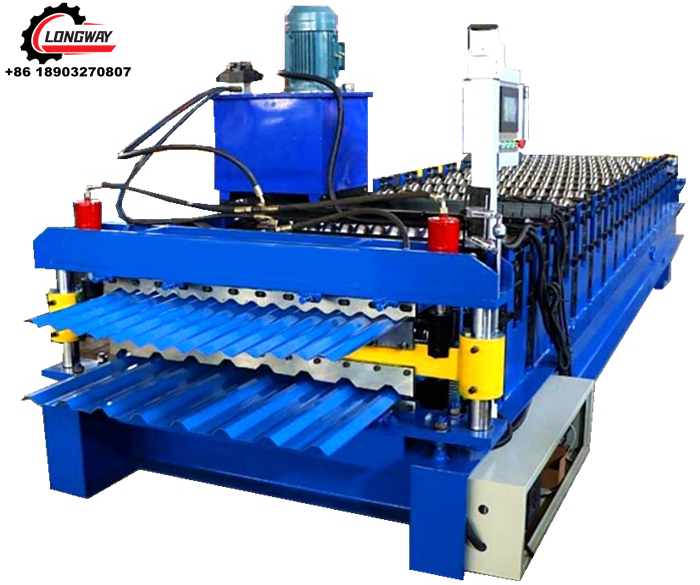

A metal deck roll forming machine is a specialized equipment designed to continuously produce metal decking sheets from coil stock. The process involves unwinding a coil of metal, feeding it through a series of rollers, and shaping it into precise dimensions and profiles. These machines can create various types of metal decking, including composite, form, and roof deck, each serving unique structural and aesthetic purposes.

The Process Explained

The roll forming process begins with loading a coil of metal, typically made from steel or aluminum, onto the machine. The coil is then uncoiled and fed into a series of rollers that progressively shape the metal into the desired profile. These rollers are meticulously engineered to ensure accuracy, producing consistent thickness and smooth edges.

Once the metal has been formed, it may undergo further processing, such as cutting to length or adding protective coatings. The end result is a robust metal deck that can support heavy loads while providing a flat surface for subsequent flooring applications.

Advantages of Using Metal Deck Roll Forming Machines

1. Cost Efficiency The mass production capabilities of roll forming machines drastically reduce labor and material costs. With the ability to produce long runs of metal decking without extensive downtime, manufacturers can achieve economies of scale.

2. Precision Engineering Roll forming machines are designed for exactness. The automated controls allow for precise adjustments, ensuring that each piece of metal decking meets the required specifications and tolerances.

metal deck roll forming machine

3. Versatility Metal deck roll forming machines can produce a variety of profiles and gauges, making them suitable for different applications. This adaptability allows manufacturers to cater to the specific needs of their clients without investing in multiple production lines.

4. Speed of Production These machines are equipped to operate at high speeds while maintaining accuracy, significantly reducing lead times. Faster production rates translate to improved project timelines, a critical factor in the competitive construction industry.

5. Durability The metal decking produced through this process is known for its strength and longevity. Metal decks are resistant to environmental factors, including moisture and pests, making them an enduring choice for building materials.

6. Sustainable Practices With a growing emphasis on sustainability in construction, metal decking offers an eco-friendly option. Metal can be recycled, and the production process can be optimized to reduce waste, contributing to greener building practices.

Applications of Metal Decking

Metal decking is widely utilized across various sectors. In commercial construction, it serves as a key structural component for floors and ceilings. Industrial applications often leverage metal decking for its ability to support heavy machinery and storage solutions. Additionally, architects and builders favor metal decking for its aesthetic appeal, allowing for creative design solutions in modern buildings.

Conclusion

The impact of metal deck roll forming machines on the construction industry cannot be overstated. They provide innovative solutions that enhance efficiency, precision, and sustainability in the production of metal decking. As the demand for robust and adaptable building materials continues to grow, these machines will play a pivotal role in shaping the future of construction and architecture.

In summary, investing in a metal deck roll forming machine is not just about acquiring equipment; it's about embracing a transformative technology that enhances productivity, reduces costs, and meets the ever-evolving demands of the construction landscape. As industries seek out advanced solutions to optimize their operations, metal deck roll forming machines stand out as a critical asset in realizing modern infrastructure goals.

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025

-

Key Features of a Roller Shutter Door Forming MachineNewsMay.23, 2025

-

Key Features of a Purlin Roll Forming MachineNewsMay.23, 2025

-

Key Features of a Cut to Length & Slitting LineNewsMay.23, 2025

-

Benefits of Using a Downspout Gutter Forming MachineNewsMay.23, 2025

-

Advantages of Using a Steel Deck Floor Roll Forming MachineNewsMay.23, 2025

-

Revolutionize Your Gutter Production with a Gutter MachineNewsMay.23, 2025