High-Quality R Panel Roll Forming Machine Manufacturing for Durable Construction Solutions

The Rise of R Panel Roll Formers A Game Changer for the Construction Industry

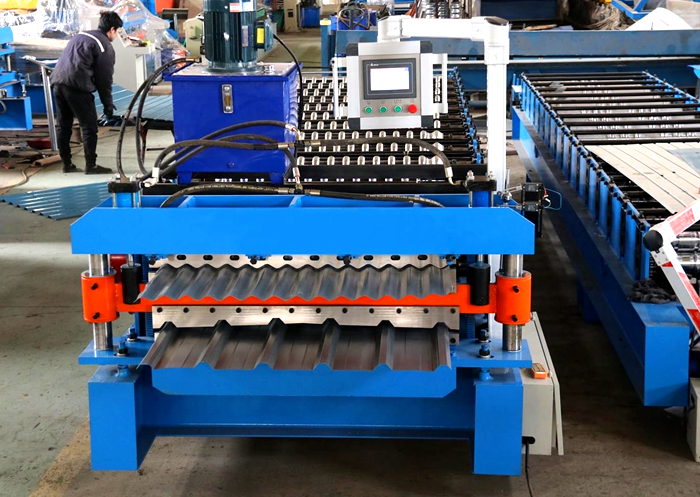

In recent years, the construction industry has witnessed significant advancements in manufacturing technologies, particularly with the introduction of the R panel roll former. This innovative machinery has revolutionized the way steel roofing and siding panels are produced, streamlining processes and enhancing efficiency. As the demand for durable and cost-effective building materials continues to grow, R panel roll formers have become an indispensable asset for many factories around the globe.

R panel roll forming involves the continuous shaping of metal sheets into specific profiles, which are then utilized for various applications in residential, commercial, and industrial construction. One of the key advantages of using R panel roll formers is their ability to produce high-quality panels at a faster rate compared to traditional methods. This not only reduces production time but also minimizes labor costs, making it an attractive option for manufacturers.

The Rise of R Panel Roll Formers A Game Changer for the Construction Industry

Moreover, the R panel design itself offers several benefits, such as excellent water runoff and superior insulation capabilities. When installed correctly, these panels create a durable barrier against the elements, contributing to energy efficiency in buildings. As energy efficiency becomes a greater concern in the construction sector, R panel products are widely recognized for their potential to reduce energy costs while maintaining structural integrity.

r panel roll former factory

From a manufacturing perspective, investing in R panel roll formers means tapping into a range of technological advancements. Modern roll forming machines are equipped with sophisticated computer controls that allow for precise adjustments and monitoring of the production process. This enhances quality control and ensures that each panel produced meets set specifications. Additionally, automation in these machines can lead to further reductions in labor costs, further solidifying the argument for their adoption.

Environmental sustainability is also a critical factor shaping the future of the construction industry. As builders and manufacturers seek to adopt greener practices, the use of R panel roll formers aligns with these initiatives. The production process generates minimal waste, and the materials used, often steel or aluminum, are recyclable. This eco-friendly aspect is increasingly appealing to consumers who prioritize sustainability in their purchasing decisions.

However, it is important to note that the success of R panel roll formers also depends on the availability of skilled operators and technicians who can manage and maintain the equipment. As the industry continues to evolve, training programs and workshops for these professionals are crucial to ensure high productivity and the longevity of the machines.

In conclusion, the emergence of R panel roll formers has marked a significant turning point in the construction industry. Their capacity to produce high-quality, durable panels efficiently positions them as a game changer for manufacturers and builders alike. As more factories embrace this technology, the benefits, including cost savings, product versatility, and sustainability, will undoubtedly enhance the overall quality of construction projects. The future of R panel roll forming appears bright, with ongoing innovations likely to pave the way for even more sophisticated manufacturing solutions in the years to come.

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025