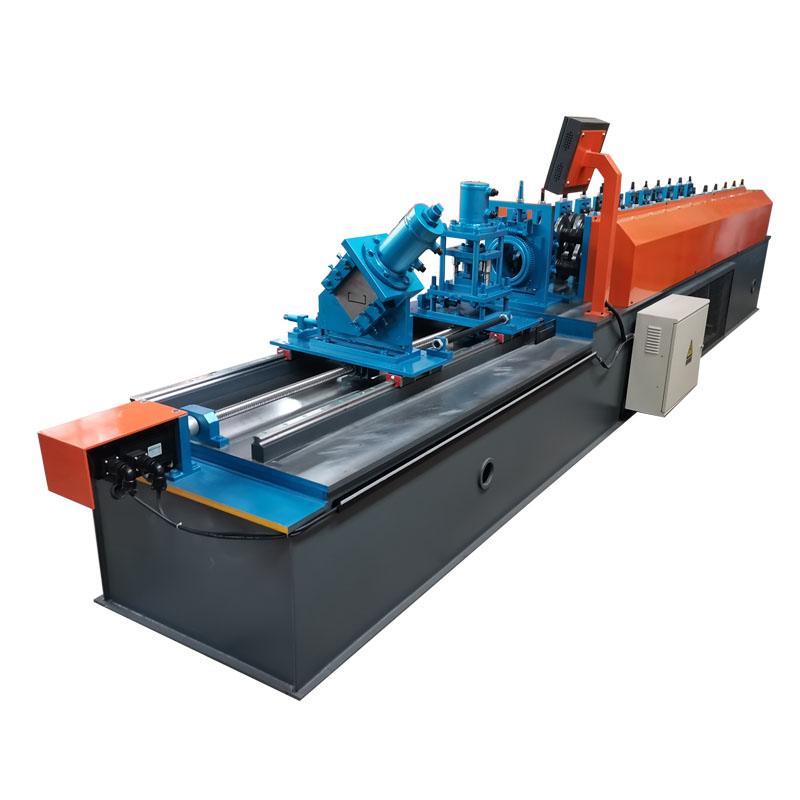

floor deck machine factory

The Floor Deck Machine Factory Innovating Construction Solutions

In the rapidly evolving construction industry, efficiency and innovation are crucial to meeting the demands of modern architecture and infrastructure. One of the vital components of this evolution is the floor deck machine, a revolutionary tool that has significantly streamlined the process of creating floor systems. This article delves into the significance of floor deck machines, explores the workings of a floor deck machine factory, and highlights the impact of this technology on construction practices.

Understanding Floor Deck Machines

Floor deck machines are specialized equipment designed to manufacture floor deck panels used in commercial and residential buildings. These panels are essential components in floor systems, providing structural support and stability. The machines typically work by forming and cutting sheet metal into specific shapes and sizes required for various construction projects. Various types of floor deck machines exist, each tailored to produce different deck profiles, such as composite and non-composite decks.

The advantages of using floor deck machines are ample. They provide precision manufacturing that reduces human error, enhance productivity by automating the production process, and ensure consistent quality in the output. Furthermore, the integration of advanced technologies, such as computer numerical control (CNC), has allowed these machines to produce complex designs quickly and efficiently.

The Role of a Floor Deck Machine Factory

A floor deck machine factory specializes in the production and assembly of floor deck machines, bringing together engineers, technicians, and skilled laborers. The factory environment is characterized by a dynamic interplay of design, engineering, and manufacturing processes.

Design and Engineering

The journey of a floor deck machine begins with the design phase. Engineers use advanced software to create blueprints that outline the machine’s structure, capabilities, and production capacity. During this phase, they also consider factors such as material suitability, energy efficiency, and ease of use. The design must also comply with industry regulations and standards to ensure safety and reliability.

Manufacturing Process

Once the design is finalized, the manufacturing process begins

. This involves several steps, such asfloor deck machine factory

1. Material Selection High-quality steel and other materials are chosen, as they directly impact the durability and performance of the machine.

2. Fabrication Components are fabricated using cutting-edge machinery, including laser cutters and welding equipment. Each part is meticulously crafted to fit together seamlessly.

3. Assembly Skilled technicians assemble the fabricated components, ensuring precision and alignment at every step. This phase often involves rigorous testing to confirm that each machine operates correctly and meets specifications.

4. Quality Assurance A robust quality assurance process is in place, involving inspections and tests at various stages of production. This guarantees that the final products are reliable and effective.

Impact on Construction Practices

The advancements in floor deck machine technology have had a profound effect on construction practices across the globe. By enabling rapid production of high-quality floor decking materials, these machines have significantly curtailed project timelines. Builders can complete projects faster, leading to reduced labor costs and increased profitability.

Moreover, the enhanced accuracy of machine-produced decks ensures that the floor systems are safer and more resilient. This reliability is crucial in today’s construction landscape, where safety and longevity are paramount.

The sustainability aspect is another critical factor. Modern floor deck machines are designed to minimize waste, utilizing materials efficiently and recycling remnants whenever possible. This aligns with the construction industry's ongoing commitment to sustainability and eco-friendly practices.

Conclusion

The role of floor deck machines and their manufacturing factories is increasingly important in the construction industry. As these technologies continue to advance, they promise to deliver even greater efficiencies, quality, and sustainability in building practices. The future of construction will undoubtedly be shaped by innovations originating from the floor deck machine factory, setting new standards in productivity and performance. The journey from design to execution holds immense potential, driving a paradigm shift in how structures are conceived, built, and maintained. As we step into an era of smart construction and automation, the impact of floor deck machines is likely to resonate for years to come.

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

-

The Role of Purlin Machine in Modern Structural BuildingNewsJun.05, 2025

-

The Advantages of Investing in a Metal Roof Sheet Making MachineNewsJun.05, 2025

-

Key Features of Hydraulic Bending MachineNewsJun.05, 2025

-

Innovations in Standing Seam Metal Roof Machine TechnologyNewsJun.05, 2025

-

High - Performance Roof Panel Machine for SaleNewsJun.05, 2025

-

Key Features to Look for in a Roof and Wall Panel MachineNewsMay.23, 2025