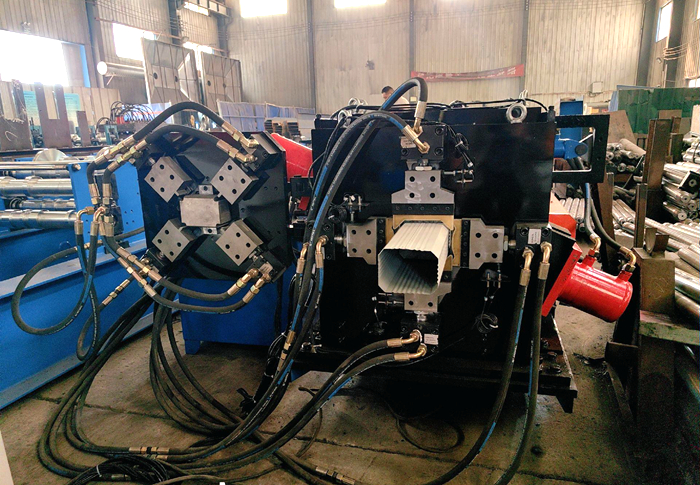

custom roll forming line machine

Custom Roll Forming Line Machine Revolutionizing Metal Fabrication

In today's fast-paced manufacturing environment, efficiency and precision are key to staying competitive. One of the standout technologies driving improvements in the metal fabrication industry is the custom roll forming line machine. This sophisticated equipment is designed to transform flat metal sheets into specific profiles through a continuous bending process. By tailoring the machinery to meet unique production needs, businesses can significantly enhance their operational effectiveness.

A custom roll forming line machine utilizes a series of rollers to gradually shape metal strips or sheets. The process begins with the input of a flat metal sheet, which then passes through multiple pairs of rollers. Each pair is strategically designed to perform a specific bend, ultimately leading to the desired final shape without the need for cutting. This continuous process minimizes waste and maximizes material utilization, making it an economically viable solution for manufacturers.

One of the most significant advantages of a custom roll forming line machine is its ability to produce highly specialized shapes quickly and consistently

. Industries such as construction, automotive, and electrical often require specific profiles for various applications. By employing a custom machine, manufacturers can create intricate designs that meet their specific requirements, ensuring that no compromise is made on quality or performance.custom roll forming line machine

Moreover, modern roll forming technologies have introduced advanced features such as automatic adjustment systems and computer controls. These innovations allow for swift changes between different product designs, making it easy to switch production lines without extensive downtime. This flexibility is particularly beneficial in today's market, where customization is increasingly in demand, and manufacturers must adapt quickly to customer specifications.

Durability and longevity are also essential considerations in the design of custom roll forming line machines. Built with robust materials, these machines can endure the rigors of continuous operation while maintaining precision. Regular maintenance and upgrades can further extend their lifespan, providing manufacturers with a worthwhile investment.

Additionally, environmental concerns cannot be overlooked. Custom roll forming minimizes waste generated during production, as the continuous process optimizes the use of raw materials. Manufacturers can also implement recycling measures for scrap materials, supporting sustainability initiatives within their operations.

In conclusion, custom roll forming line machines represent a vital advancement in the metal fabrication industry. Their capacity for high precision, efficiency, and flexibility makes them indispensable to manufacturers seeking a competitive edge. By tailoring these machines to fit specific production needs, companies can not only enhance their productivity but also improve their environmental footprint, aligning with modern manufacturing standards. With ongoing innovations, the future of custom roll forming looks bright, promising even greater efficiencies and capabilities for the industry.

-

The Role of Hydraulic Systems in Sheet Metal SlittersNewsAug.23, 2025

-

Customization Options in Metal Deck Roll Forming MachinesNewsAug.23, 2025

-

Safety Tips When Using a Gutter Making MachineNewsAug.23, 2025

-

Key Components of a C Purlin Machine ExplainedNewsAug.23, 2025

-

Maintenance Tips for a Steel Angle Roll Forming MachineNewsAug.23, 2025

-

Portable Metal Roofing Machine Applications in Remote ConstructionNewsAug.23, 2025

-

Roof Panel MachineNewsAug.18, 2025